TSN’s cold formed steel bridging connections work together with almost any stud spacing on your cold formed steel framing job to resist weak axis buckling and torsional rotation of members. Used in both interior and exterior applications, TSN’s line of bridging products can save hours of installation time and thousands of dollars in a single project.

Below are some of the highlights of our cold formed steel studs framing (light gauge metal) bridging products.

Quality:

- Load-rated positive mechanical attachment at each stud

- Utilizes only certified, 50ksi steel

- Accommodate most wall stud spacing, including 8″, 12″, 16″ & 24″ centers

Value:

- Fast installation, where no clamping or welding is required

- Guide holes provided for quick and accurate fastener placement

- TSN’s bridging products work flawlessly together as a system

Bridging Background & Requirements:

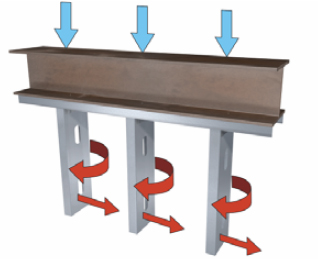

Bridging for load bearing and curtain wall studs is needed to resist the following forces:

- Weak axis buckling induced by axial compression load.

- Torsion induced by wind load.

As axial compression and lateral wind loads are applied, wall studs react with weak axis buckling and torsional rotation. To offset these forces, a form of bridging is incorporated into the wall system. Bridging loads accumulate over the run of the wall, requiring transfer of lateral forces in bridging at columns or to the floor slab into the structural load path to the foundation.

AISI Wall Stud Design Standard (S211) and AISI Specification (S100) provide the load and stiffness requirements for bracing members due to the effects of axial compression load and wind load as given in the on the following tab. Contact TSN Technical Support (888) 474-4876 if further information is needed regarding wall bridging design.

Bridging Force Diagram

Bridging Use Tables

| Bridging Clip Chart: Design Wind Pressure, Stud Spacing and Maximum Bridging Spacing | |||||||||||||||

| Section | 10psf | 20psf | 25psf | ||||||||||||

| 24″ o.c. | 16″ o.c. | 24″ o.c. | 16″ o.c. | 24″ o.c. | |||||||||||

| 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | |

| 600S162-33, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | N/A |

| 600S162-43, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 600S162-54, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 600S162-68, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 600S162-97, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 600S200-33, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 3 | BC-33, 3 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 3 | BC-43, 3 | BC-43, 3 |

| 600S200-43, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 |

| 600S200-54, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 3 |

| 600S200-68, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 600S200-97, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 800S162-33, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 |

| 800S162-43, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 |

| 800S162-54, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 800S162-68, 50 ksi | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 |

| 800S162-97, 50 ksi | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 |

| 800S200-33, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 3 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-43, 1 | BC-33, 3 | BC-43, 3 |

| 800S200-43, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 3 |

| 800S200-54, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 |

| 800S200-68, 50 ksi | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 |

| 800S200-97, 50 ksi | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 |

| Channel / Clip Bridging Chart: Design Wind Pressure and Unsupported Wall Height | |||||||||||||||

| Section | 30psf | 40psf | 50psf | ||||||||||||

| 16″ o.c. | 24″ o.c. | 16″ o.c. | 24″ o.c. | 16″ o.c. | |||||||||||

| 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | |

| 600S162-33, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 3 | N/A | BC-33, 1 | BC-33, 3 | N/A | BC-43, 3 | N/A | N/A | BC-33, 3 | BC-43, 3 | N/A |

| 600S162-43, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | N/A | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | N/A | BC-33, 1 | BC-33, 1 | N/A |

| 600S162-54, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | N/A | BC-33, 1 | BC-33, 1 | BC-33, 3 |

| 600S162-68, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 600S162-97, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 600S200-33, 33 ksi | BC-33, 1 | BC-33, 3 | BC-33, 3 | BC-43, 3 | BC-43, 3 | N/A | BC-33, 3 | BC-43, 3 | BC-43, 3 | BC600 | BC600 | N/A | BC-43, 3 | BC-43, 3 | N/A |

| 600S200-43, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-43, 1 | BC600 | N/A | BC-43, 1 | BC-43, 1 | BC-43, 3 |

| 600S200-54, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 3 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC600 | BC600 | BC-33, 3 | BC-43, 1 | BC600 |

| 600S200-68, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 3 | BC-43, 3 | BC600 | BC-33, 1 | BC-33, 3 | BC-43, 1 |

| 600S200-97, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 |

| 800S162-33, 33 ksi | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 3 | N/A | BC-43, 1 | BC-43, 1 | BC-33, 3 | BC-33, 3 | BC-43, 3 | N/A | BC-43, 1 | BC-33, 3 | N/A |

| 800S162-43, 33 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 3 | N/A | BC-43, 1 | BC-43, 1 | BC-33, 3 |

| 800S162-54, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-33, 3 | BC-33, 1 | BC-33, 1 | BC-43, 1 |

| 800S162-68, 50 ksi | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 |

| 800S162-97, 50 ksi | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 |

| 800S200-33, 33 ksi | BC-43, 1 | BC-43, 1 | BC-33, 3 | BC-33, 3 | BC-43, 3 | BC800 | BC-33, 3 | BC-33, 3 | BC-43, 3 | BC800 | BC800 | BC800 | BC-43, 3 | BC800 | BC800 |

| 800S200-43, 33 ksi | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 3 | BC-43, 3 | BC-43, 1 | BC-33, 3 | BC-33, 3 | BC-43, 3 | BC800 | BC800 | BC-33, 3 | BC-43, 3 | BC800 |

| 800S200-54, 50 ksi | BC-33, 1 | BC-33, 1 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 3 | BC-33, 1 | BC-43, 1 | BC-43, 1 | BC-33, 3 | BC-43, 3 | BC800 | BC-43, 1 | BC-33, 3 | BC-43, 3 |

| 800S200-68, 50 ksi | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 |

| 800S200-97, 50 ksi | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 | BC800 |

Notes:

- Listed wind pressures represent calculated design wind pressure (0.6W based on 2015 IBC).

- Allowable pressures are limited by published test data allowable torsional moments for bridging elements.

- Torsional moment acting on bridging elements is calculated as:

M = 1.5 x Wind Pressure x Bridging Spacing x Stud Spacing x m (distance from stud web to shear center). - Wall height is assumed twice the bridging spacing.

- BuckleBridge® stud spacing is fixed at 16″.

- Stud design is limited by its flexural strength calculated with torsional bracing assumed at the bridging spacing and kφ = 0 and deflection limit of L/360.

- 20 psf and higher wind pressures have been multiplied by 0.7 for deflection determination, in accordance with footnote “f” of IBC table 1604.3. The 10 psf pressure has not been reduced for deflection checks.

Nomenclature:

- BC-33, 1 – BridgeClip BC-33 with (1) #10 screw fastener into bridging member.

- BC-33, 3 – BridgeClip BC-33 with (1) #10 screw fastener into bridging member and (2) #10 screw fasteners into the web of the stud.

- BC-43, 1 – BridgeClip BC-43 with (1) #10 screw fastener into bridging member.

- BC-43, 3 – BridgeClip BC-43 with (1) #10 screw fastener into bridging member and (2) #10 screw fasteners into the web of the stud.

- BC600 – BridgeClip BC600 with (2) #10 screw fasteners into bridging member and (2) #10 screw fasteners into the web of the stud.

- BC800 – BridgeClip BC800 with (2) #10 screw fasteners into bridging member and (2) #10 screw fasteners into the web of the stud.

| BuckleBridge® Bridging Chart: Design Wind Pressure and Maximum Bridging Spacing | |||||||||||||||

| Section | 20psf | 25psf | 30psf | 40psf | 50psf | ||||||||||

| 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | 5′ | 6′ | 7′ | |

| 600S162-33, 33 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | N/A | BKB | BKB | N/A |

| 600S162-43, 33 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | N/A |

| 600S162-54, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 600S162-68, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 600S162-97, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 600S200-33, 33 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | N/A |

| 600S200-43, 33 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 600S200-54, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 600S200-68, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 600S200-97, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S162-33, 33 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | N/A |

| 800S162-43, 33 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S162-54, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S162-68, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S162-97, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S200-33, 33 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S200-43, 33 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S200-54, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S200-68, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

| 800S200-97, 50 ksi | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB | BKB |

Notes:

- Listed wind pressures represent calculated design wind pressure (0.6W based on 2015 IBC).

- Allowable pressures are limited by published test data allowable torsional moments for bridging elements.

- Torsional moment acting on bridging elements is calculated as:

M = 1.5 x Wind Pressure x Bridging Spacing x Stud Spacing x m (distance from stud web to shear center). - Wall height is assumed twice the bridging spacing.

- BuckleBridge® stud spacing is fixed at 16″.

- Stud design is limited by its flexural strength calculated with torsional bracing assumed at the bridging spacing and kφ = 0 and deflection limit of L/360.

- 20 psf and higher wind pressures have been multiplied by 0.7 for deflection determination, in accordance with footnote “f” of IBC table 1604.3. The 10 psf pressure has not been reduced for deflection checks.

Nomenclature:

- BKB – BuckleBridge with (1) #10 screw on alternate sides of the BuckleBridge at 3rd stud (48″ o.c.) Use (2) #10 screws at end of wall run.

Follow us on Social Media