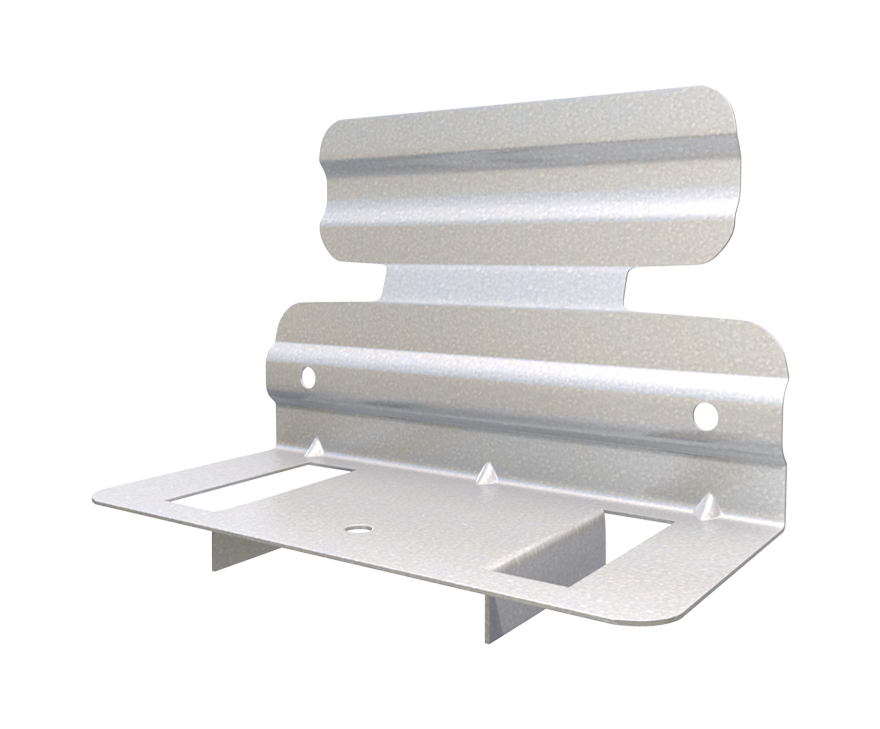

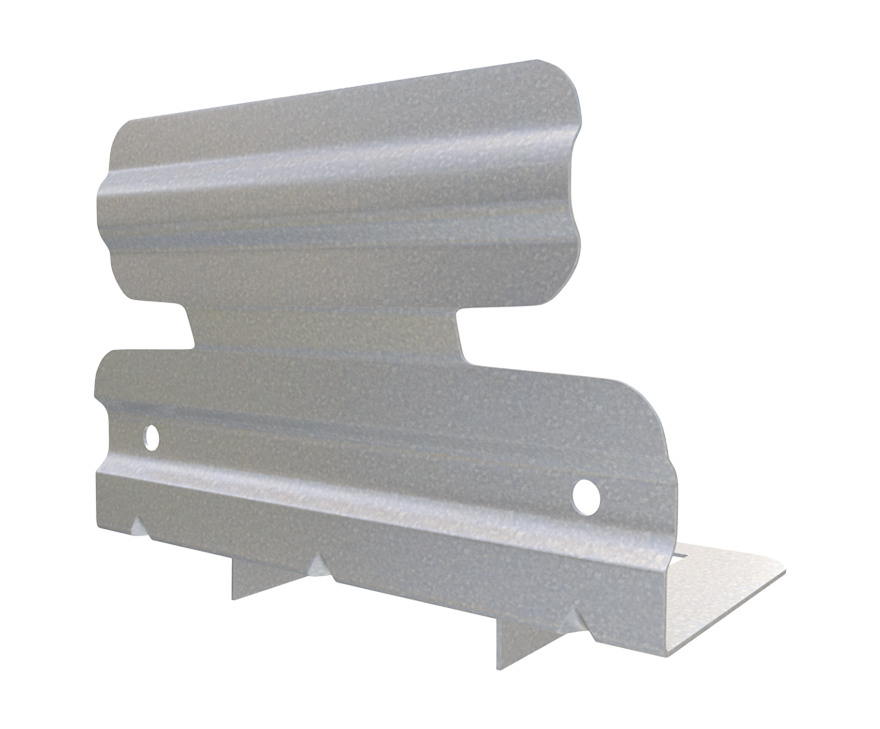

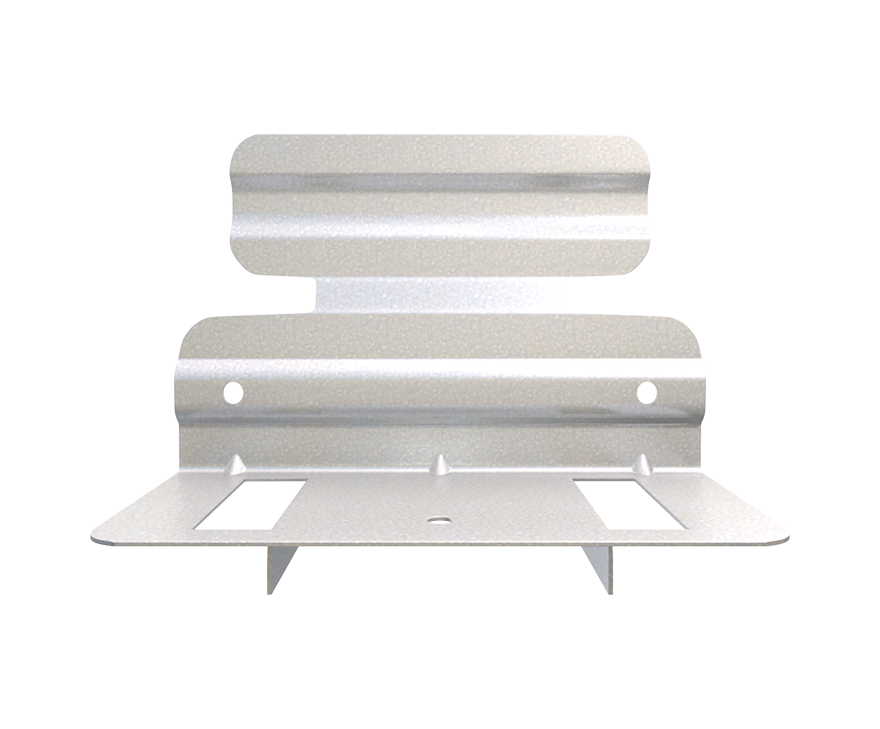

BridgeClip®

Features

- Fast installation

- No clamping

- No welding

- Guide holes provided for quick and accurate fastener placement

- Rounded edges for safety

- Laborers are working on installation, not cutting angle

- Certified, 50ksi steel, G90 galvanized coating

- 33 Mil thickness (BC-33)

- 43 Mil thickness (BC-43, BC600 & BC800)

Order Information

| Designation | Qty/Box | Lbs/Box | Qty/Skid | Lbs/Skid |

| BC-33 | 250 | 30 | 12,000 | 1,440 |

| BC-43 | 200 | 37 | 9,600 | 1,776 |

| BC600 | 150 | 30 | 7,200 | 1,440 |

| BC800 | 100 | 28 | 4,800 | 1,344 |

Nomenclature

BridgeClip is available in 3⅝”, 6″ and 8″ and is designated by the type, BC. Designations are BC-33, BC-43, BC600 & BC800.

Example: 6″ Stud

Designate: BC600

Material Composition

BC-33: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 33mil minimum thickness (20 gauge, 0.0346″ design thickness) with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating.

BC-43, BC600 & BC800: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 43mil minimum thickness (18 gauge, 0.0451″ design thickness) with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating.

Catalogs

|

|

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

US Patents #5,904,023

BridgeClip Downloads

BridgeClip® Applications

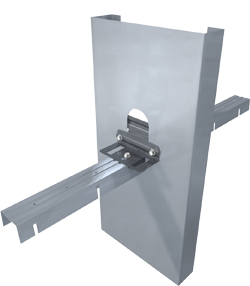

BridgeClip for 3" & 4" Studs

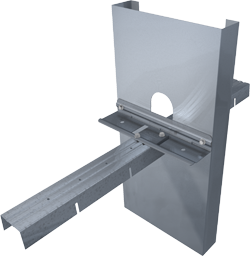

BridgeClip for 6" & 8" Studs

Installation Instructions

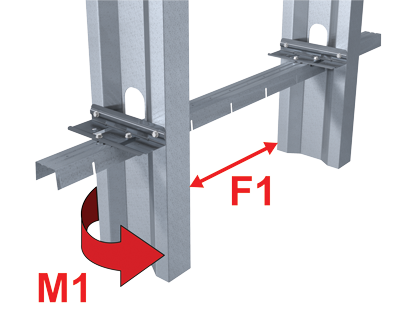

Allowable Loads

| BridgeClip | Stud Depth | Stud Thickness (mils) (ga) | Axially Loaded Stud, Allowable Brace Strength F1 (lbs) | Laterally Loaded Stud, Allowable Torsional Moment M1 (in.lbs) |

| BC-33, 1 | 3.625/4 | 33 (20) | 75 | 132 |

| 43 (18) | 143 | |||

| 54 (16) | 156 | |||

| BC-43, 1 | 3.625/4 | 33 (20) | 112 | 168 |

| 43 (18) | 179 | |||

| 54 (16) | 192 | |||

| BC-33, 3 | 3.625/4 | 33 (20) | 360 | 192 |

| 43 (18) | 221 | |||

| 54 (16) | 252 | |||

| BC-43, 3 | 3.625/4 | 33 (20) | 433 | 240 |

| 43 (18) | 297 | |||

| 54 (16) | 360 | |||

| BC-33, 1 | 6 | 33 (20) | 75 | 192 |

| 43 (18) | 252 | |||

| 54 (16) | 264 | |||

| 68 (14) | 307 | |||

| 97 (12) | 396 | |||

| BC-43, 1 | 6 | 33 (20) | 112 | 240 |

| 43 (18) | 372 | |||

| 54 (16) | 324 | |||

| 68 (14) | 371 | |||

| 97 (12) | 468 | |||

| BC-33, 3 | 6 | 33 (20) | 360 | 228 |

| 43 (18) | 254 | |||

| 54 (16) | 288 | |||

| 68 (14) | 324 | |||

| 97 (12) | 408 | |||

| BC-43, 3 | 6 | 33 (20) | 433 | 324 |

| 43 (18) | 384 | |||

| 54 (16) | 372 | |||

| 68 (14) | 407 | |||

| 97 (12) | 480 | |||

| BC600 | 6 | 33 (20) | 170 | 684 |

| 43 (18) | 218 | 792 | ||

| 54 (16) | 360 | 864 | ||

| 68 (14) | 887 | |||

| 97 (12) | 936 | |||

| BC-33, 1 | 8 | 33 (20) | 75 | 144 |

| 43 (18) | 178 | |||

| 54 (16) | 216 | |||

| BC-43, 1 | 8 | 33 (20) | 112 | 192 |

| 43 (18) | 232 | |||

| 54 (16) | 276 | |||

| BC-33, 3 | 8 | 33 (20) | 360 | 240 |

| 43 (18) | 280 | |||

| 54 (16) | 324 | |||

| BC-43, 3 | 8 | 33 (20) | 433 | 288 |

| 43 (18) | 339 | |||

| 54 (16) | 396 | |||

| BC800 | 8 | 33 (20) | 170 | 756 |

| 43 (18) | 218 | 790 | ||

| 54 (16) | 360 | 828 | ||

| 68 (14) | 851 | |||

| 97 (12) | 900 |

Notes:

- Listed ASD allowable loads are based on ultimate test data divided by a factor of safety.

- Listed ASD allowable loads are limited by screw shear or pullout at stud web.

Table Nomenclature:

| Table Nomenclature | Clip | Qty #10 Screws into Bridging | Qty #10 Screws into Stud |

| BC-33, 1 | BC-33 | 1 | 0 |

| BC-33, 3 | BC-33 | 1 | 2 |

| BC-43, 1 | BC-43 | 1 | 0 |

| BC-43, 3 | BC-43 | 1 | 2 |

| BC600 | BC600 | 2 | 2 |

| BC800 | BC800 | 2 | 2 |

Load Direction

Follow us on Social Media