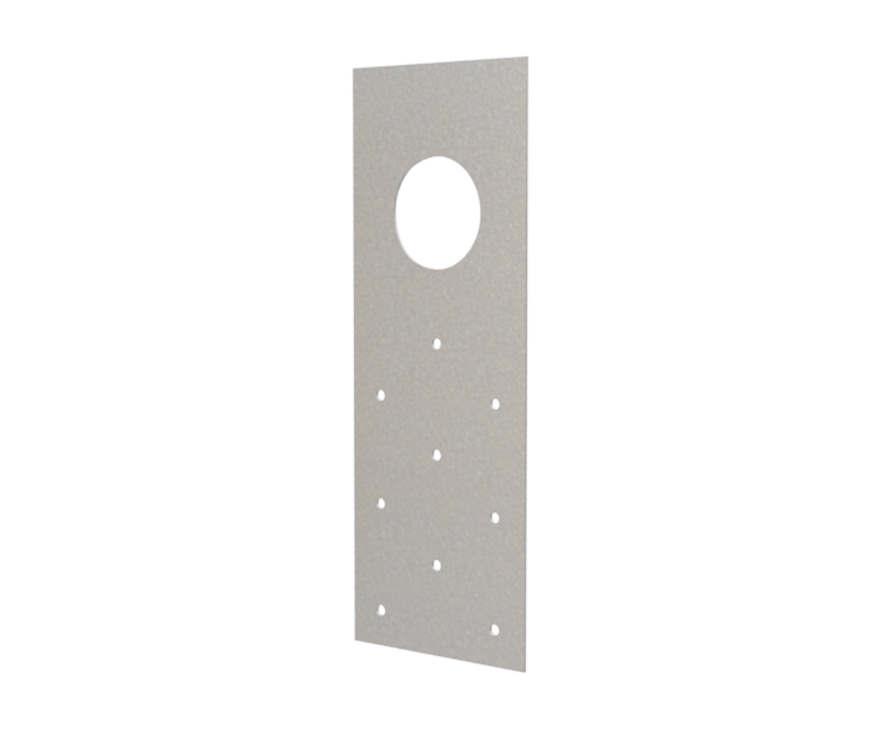

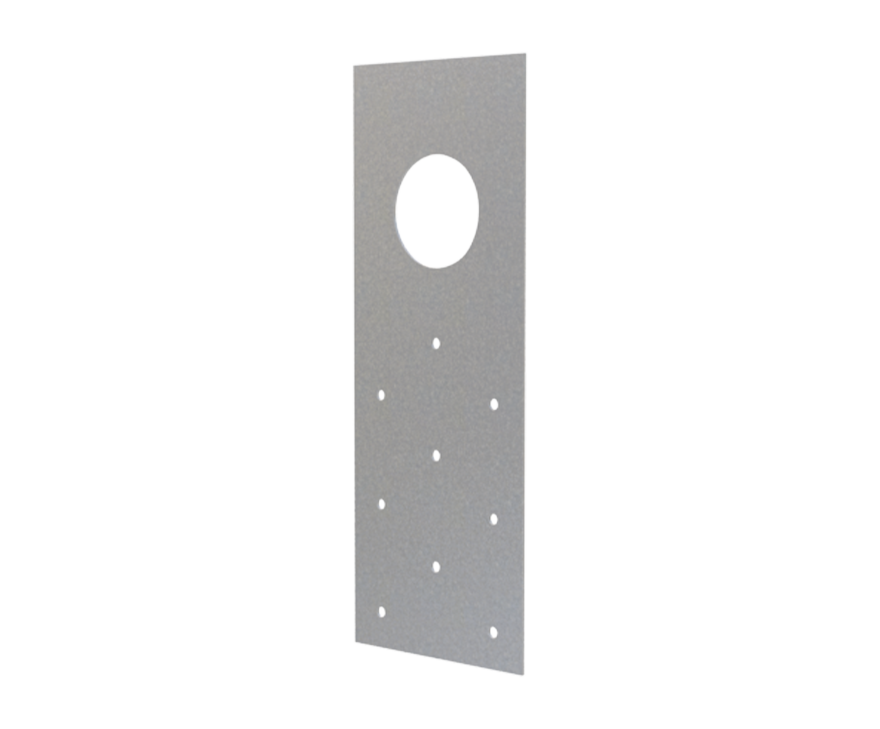

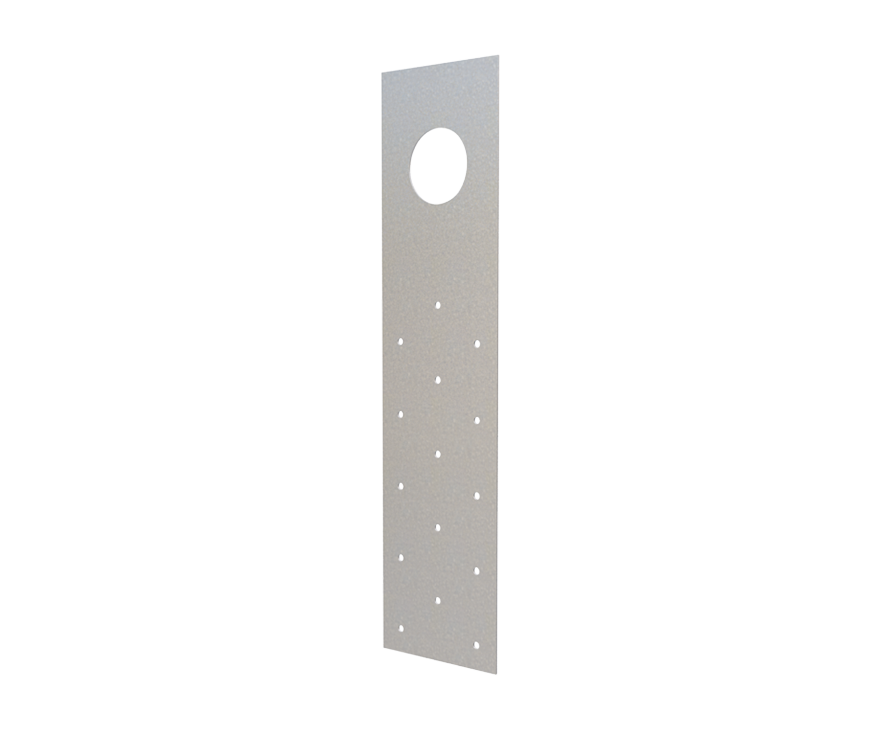

StiffClip® PLC

Features

- Safely lift and place assembled wall components

- Attaches easily through pre-punched guide holes

- Utilizes only certified, 50ksi steel

- Adaptable for multiple configurations

Order Information

| Designation | Qty/Box | Lbs/Box | Qty/Skid | Lbs/Skid |

| PLC-8-97 | 50 | 25 | 2,000 | 1,000 |

| PLC-12-97 | 50 | 37 | 2,000 | 1,480 |

Nomenclature

StiffClip PLC is available in two sizes and is designated by the length of the clip, followed by mil thickness (-97).

Example: 8″ connector

Designate: StiffClip® PLC-8-97

Material Composition

Catalogs

|

|

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

StiffClip® PLC Downloads

StiffClip® PLC Applications

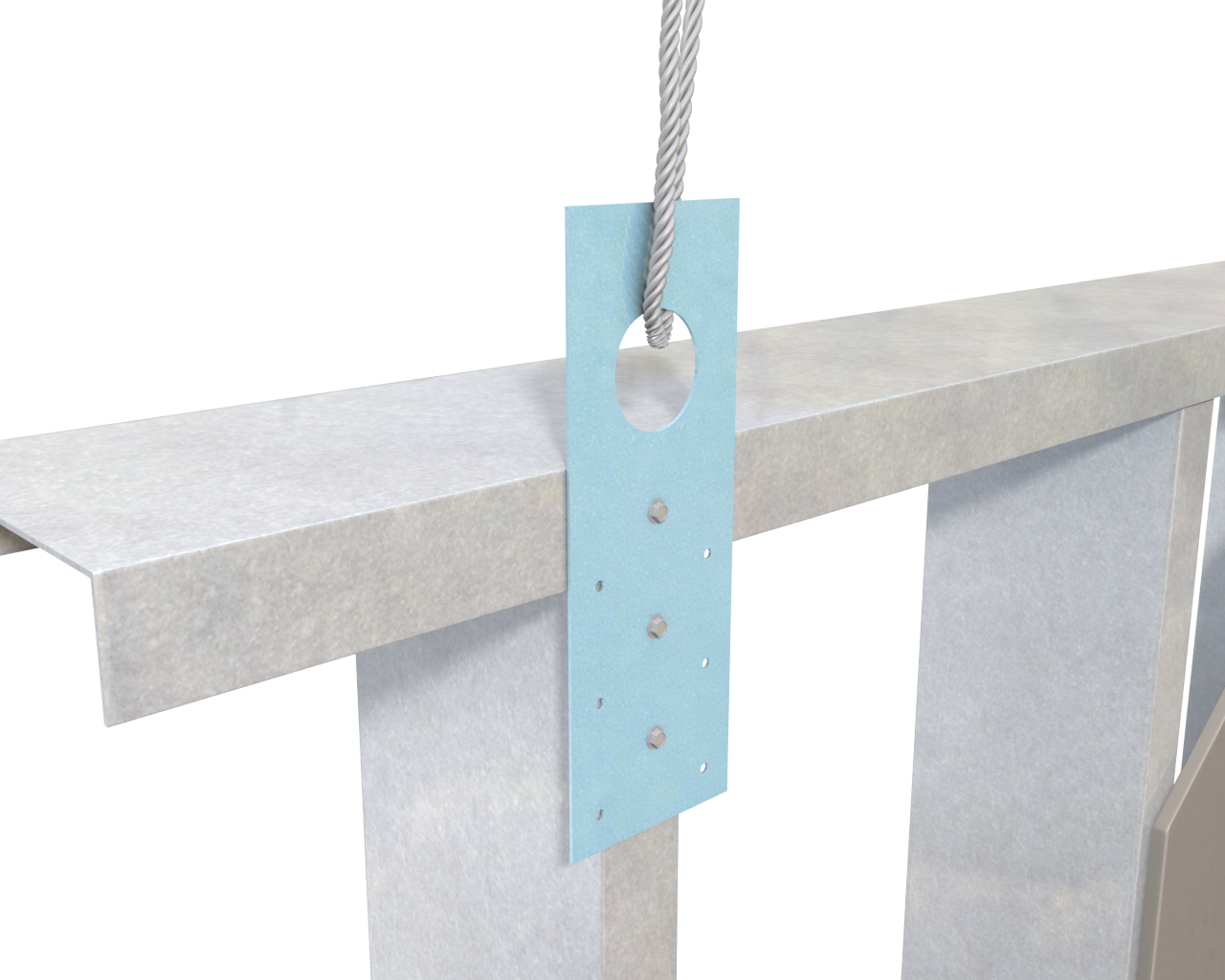

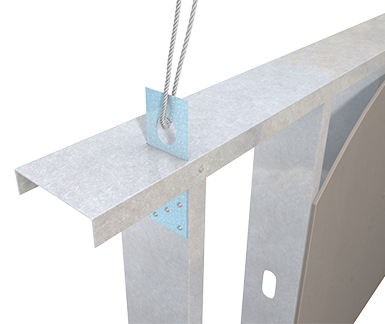

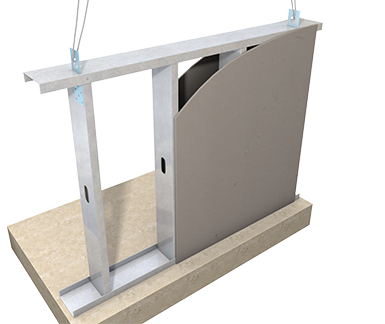

Lifting Panel into Position

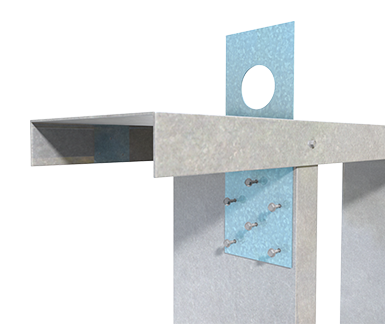

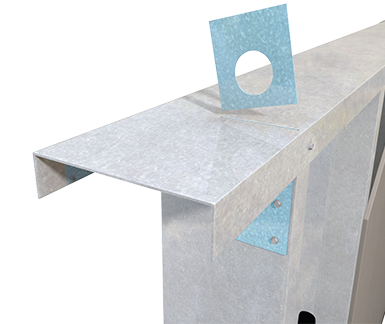

Attachment to Wall at Intermediate Stud

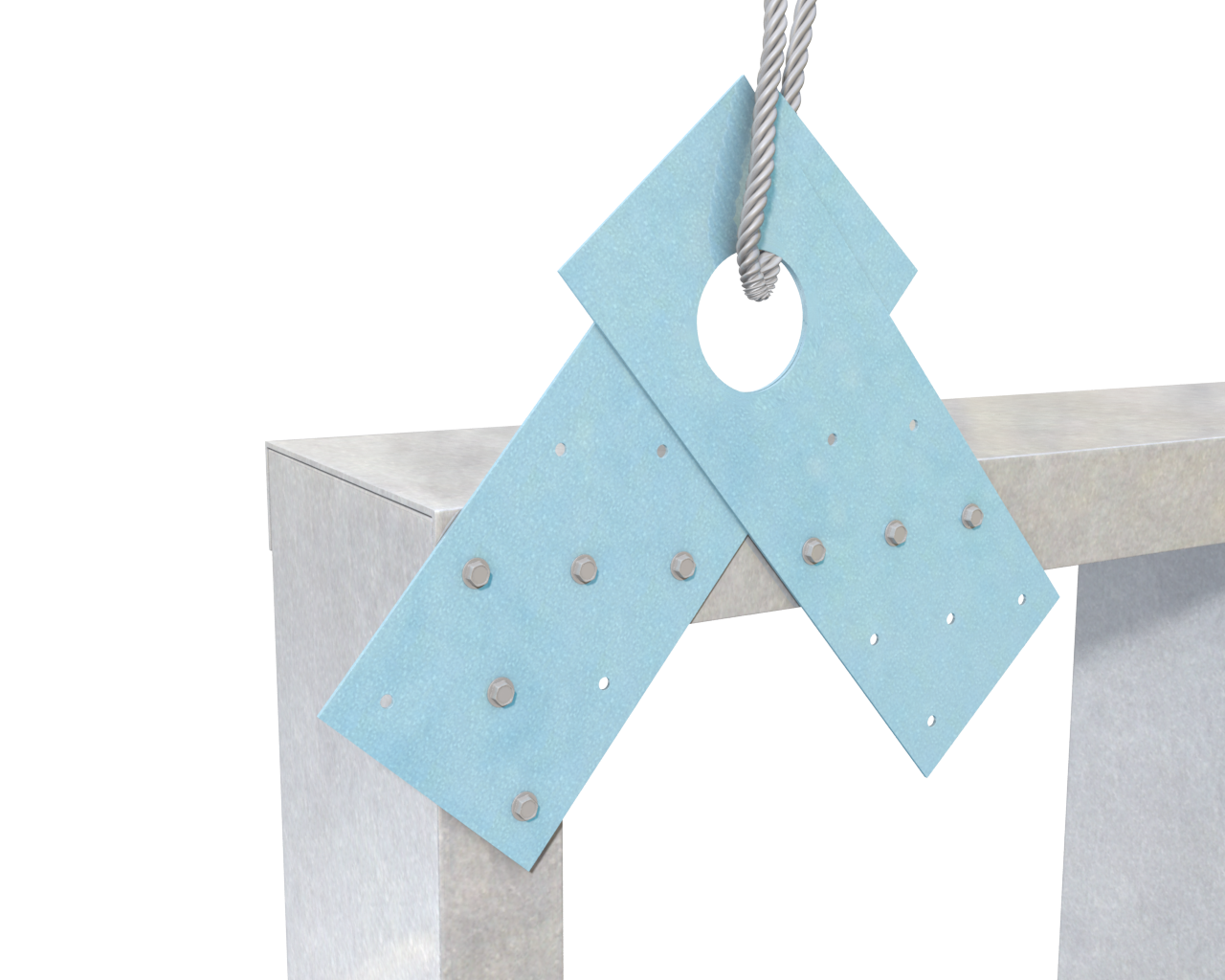

Double Attachment to Wall at End Stud

Attachment to Stud Web

Installation Instructions

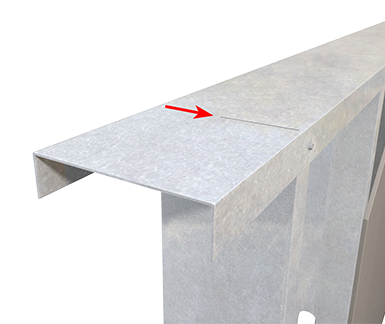

Step 1: Cut slot in top track of panel

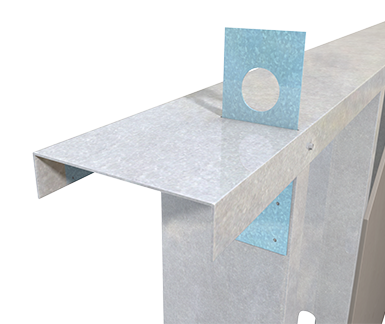

Step 2: Insert PLC through slot

Step 3: Attach StiffClip® PLC to stud through guide holes with approved screws

Step 4: Insert lifting cable through 1.5" hole

Step 5: Lift panel into place

Step 6: Trim top of clip flush with the top track of installed panel

Allowable Loads

| StiffClip® PLC, Recommended Allowable Load for Steel Framing (lbs): F3 & F2 | |||||||||||||

| Stud | F3 | F2 | |||||||||||

| PLC-8 | PLC-12 | PLC-8 | PLC-12 | ||||||||||

| Thickness Mils (ga) | Yield Strength (ksi) | w/3 #10 Screws | w/5 #10 Screws | w/9 #10 Screws | w/5 #10 Screws | w/9 #10 Screws | w/15 #10 Screws | w/3 #10 Screws | w/5 #10 Screws | w/9 #10 Screws | w/5 #10 Screws | w/9 #10 Screws | w/15 #10 Screws |

| 33 (20) | 33 | 531 | 885 | 1,593 | 885 | 1,593 | 1,915 | 126 | 211 | 312 | 182 | 267 | 496 |

| 33 (20) | 50 | 765 | 1,275 | 1,915 | 1,275 | 1,915 | 1,915 | 181 | 303 | 449 | 263 | 385 | 714 |

| 43 (18) | 33 | 789 | 1,315 | 1,915 | 1,315 | 1,915 | 1,915 | 187 | 313 | 463 | 271 | 397 | 736 |

| 43 (18) | 50 | 1,140 | 1,900 | 1,915 | 1,900 | 1,915 | 1,915 | 270 | 452 | 669 | 391 | 574 | 1,064 |

| 54 (16) | 33 | 1,119 | 1,850 | 1,915 | 1,850 | 1,915 | 1,915 | 263 | 440 | 651 | 381 | 559 | 1,036 |

| 54 (16) | 50 | 1,602 | 1,915 | 1,915 | 1,915 | 1,915 | 1,915 | 379 | 635 | 940 | 550 | 806 | 1,270 |

| 68 (14) | 50 | 1,644 | 1,915 | 1,915 | 1,915 | 1,915 | 1,915 | 389 | 652 | 964 | 564 | 827 | 1,270 |

| 97 (12) | 50 | 1,644 | 1,915 | 1,915 | 1,915 | 1,915 | 1,915 | 389 | 652 | 964 | 564 | 827 | 1,270 |

| 118 (10) | 50 | 1,644 | 1,915 | 1,915 | 1,915 | 1,915 | 1,915 | 389 | 652 | 964 | 564 | 827 | 1,270 |

Notes

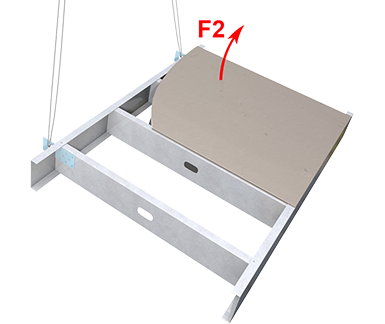

- Clip F2 allowable load = 1.270 kips based on testing.

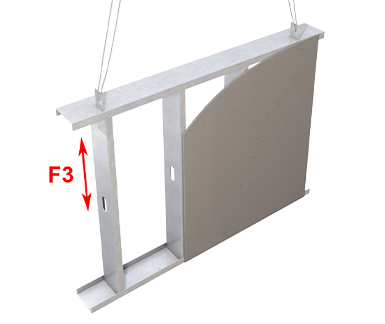

- Clip F3 allowable load = 1.915 kips based on testing.

- Attachment is made with #10 scews minimum.

- Spacing between clips to be controlled by weight of panel and presence of a spreader bar or a load distribution member.

F2 Load Direction

F3 Load Direction

Follow us on Social Media