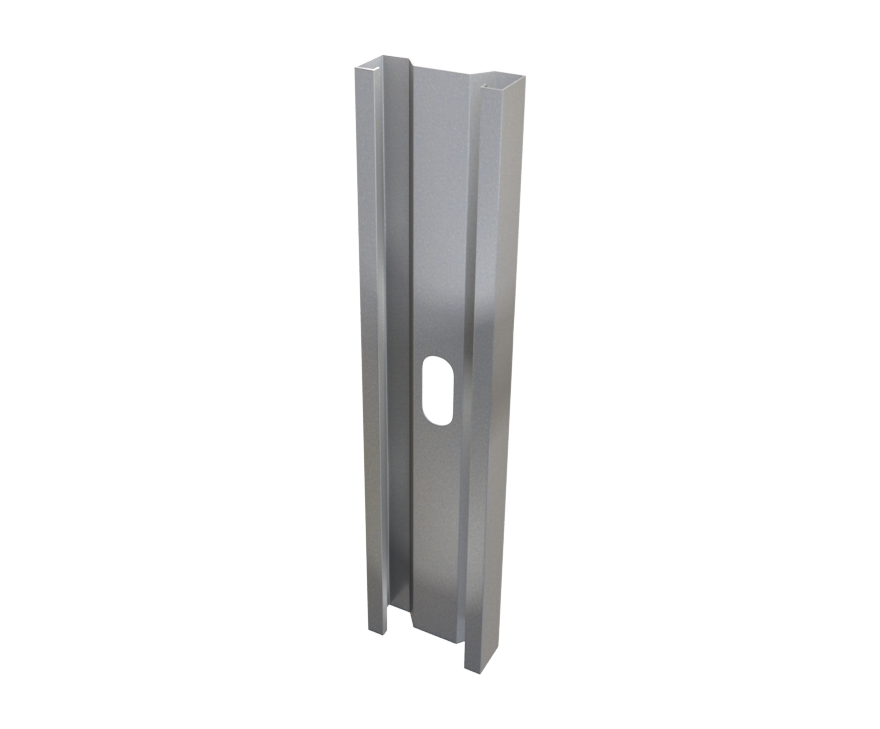

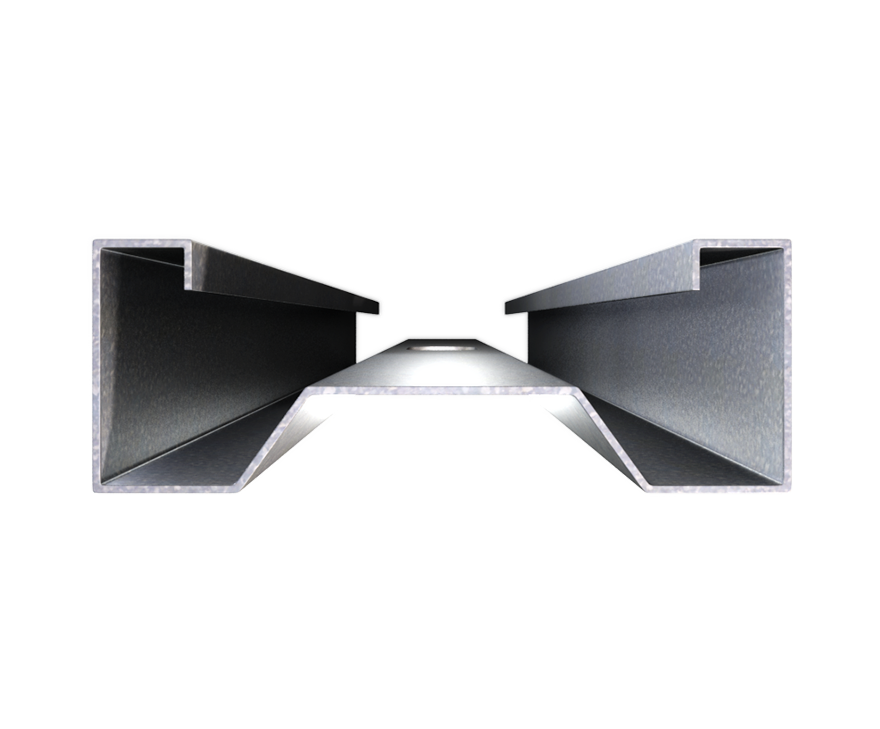

SigmaStud®

Each bend made to a flat LSF (light gauge metal) element increases load capacity over a standard stud section with the same material thickness. Six extra bends result in delivering the most efficient LSF load-bearing stud member available in the industry.

Features

- Increases load capacity over a standard “C-shaped” stud of the same thickness, reducing overall materials needed (14ga “C-shaped” to 18ga “SG” common)

- Re-defines previous limitations considered for utilization of steel studs in building construction

- Larger flange width increases area for fasteners

- Axial load capacity tables compatible with recent code changes

- Lighter weight results in shipping efficiencies and easier handling & faster connections

- Screw size decreases with thinner material thickness of member material

- Eliminate or reduce double studs / stud packs and their attachments to each other

- Increased load capacity produces more cost-effective options for designing load bearing walls for clients

Order Information

Material Composition

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. SigmaStud® can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

SigmaStud® Downloads

SigmaStud® Applications

SigmaStud with Hollowcore Slab

Installation Instructions

|

|

|

| SigmaStud® Product Profile | |||||||||||

| Section (All 50 ksi) |

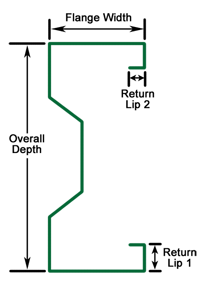

Overall Depth | Flange Width | Web Flat | Web Return | Web Return | Web Inside | Return Lip 1 | Return Lip 2 | Inside Bend Radius | Design Thickness |

Unit Weight |

| D | B | A | C | E | N | d1 | d2 | R | t | (lbs/ft) | |

| (in) | (in) | (in) | (in) | (in) | (in) | (in) | (in) | (in) | (in) | ||

| 350SG200-33 | 3.5 | 2 | 3.5 | N/A | N/A | N/A | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.078 |

| 350SG200-43 | 3.5 | 2 | 3.5 | N/A | N/A | N/A | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.400 |

| 350SG200-54 | 3.5 | 2 | 3.5 | N/A | N/A | N/A | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.749 |

| 350SG200-68 | 3.5 | 2 | 3.5 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.192 |

| 350SG200-97 | 3.5 | 2 | 3.5 | N/A | N/A | N/A | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.092 |

| 350SG250-33 | 3.5 | 2.5 | 3.5 | N/A | N/A | N/A | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.196 |

| 350SG250-43 | 3.5 | 2.5 | 3.5 | N/A | N/A | N/A | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.553 |

| 350SG250-54 | 3.5 | 2.5 | 3.5 | N/A | N/A | N/A | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.942 |

| 350SG250-68 | 3.5 | 2.5 | 3.5 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.435 |

| 350SG250-97 | 3.5 | 2.5 | 3.5 | N/A | N/A | N/A | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.438 |

| 350SG350-68 | 3.5 | 3.5 | 3.5 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.920 |

| 362SG200-33 | 3.625 | 2 | 3.625 | N/A | N/A | N/A | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.093 |

| 362SG200-43 | 3.625 | 2 | 3.625 | N/A | N/A | N/A | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.419 |

| 362SG200-54 | 3.625 | 2 | 3.625 | N/A | N/A | N/A | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.773 |

| 362SG200-68 | 3.625 | 2 | 3.625 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.222 |

| 362SG200-97 | 3.625 | 2 | 3.625 | N/A | N/A | N/A | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.135 |

| 362SG250-33 | 3.625 | 2.5 | 3.625 | N/A | N/A | N/A | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.210 |

| 362SG250-43 | 3.625 | 2.5 | 3.625 | N/A | N/A | N/A | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.572 |

| 362SG250-54 | 3.625 | 2.5 | 3.625 | N/A | N/A | N/A | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.966 |

| 362SG250-68 | 3.625 | 2.5 | 3.625 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.465 |

| 362SG250-97 | 3.625 | 2.5 | 3.625 | N/A | N/A | N/A | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.481 |

| 362SG350-68 | 3.625 | 3.5 | 3.625 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.950 |

| 400SG200-33 | 4 | 2 | 4 | N/A | N/A | N/A | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.137 |

| 400SG200-43 | 4 | 2 | 4 | N/A | N/A | N/A | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.477 |

| 400SG200-54 | 4 | 2 | 4 | N/A | N/A | N/A | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.846 |

| 400SG200-68 | 4 | 2 | 4 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.313 |

| 400SG200-97 | 4 | 2 | 4 | N/A | N/A | N/A | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.265 |

| 400SG250-33 | 4 | 2.5 | 4 | N/A | N/A | N/A | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.255 |

| 400SG250-43 | 4 | 2.5 | 4 | N/A | N/A | N/A | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.630 |

| 400SG250-54 | 4 | 2.5 | 4 | N/A | N/A | N/A | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.038 |

| 400SG250-68 | 4 | 2.5 | 4 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.556 |

| 400SG250-97 | 4 | 2.5 | 4 | N/A | N/A | N/A | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.611 |

| 400SG350-68 | 4 | 3.5 | 4 | N/A | N/A | N/A | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.041 |

| 400SG350-97 | 4 | 3.5 | 4 | N/A | N/A | N/A | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.303 |

| 400SG350-118 | 4 | 3.5 | 4 | N/A | N/A | N/A | 0.7684 | 0.5 | 0.105 | 0.1242 | 5.216 |

| 550SG162-33 | 5.5 | 1.6 | 1 | 1 | 0.63 | 2.25 | 0.5000 | 0 | 0.105 | 0.0346 | 1.232 |

| 550SG162-43 | 5.5 | 1.6 | 1 | 1 | 0.63 | 2.25 | 0.5000 | 0 | 0.105 | 0.0451 | 1.598 |

| 550SG200-33 | 5.5 | 2 | 1 | 1 | 0.63 | 2.25 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.438 |

| 550SG200-43 | 5.5 | 2 | 1 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.869 |

| 550SG200-54 | 5.5 | 2 | 1 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.338 |

| 550SG200-68 | 5.5 | 2 | 1 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.933 |

| 550SG200-97 | 5.5 | 2 | 1 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.147 |

| 550SG250-33 | 5.5 | 2.5 | 1 | 1 | 0.63 | 2.25 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.556 |

| 550SG250-43 | 5.5 | 2.5 | 1 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.023 |

| 550SG250-54 | 5.5 | 2.5 | 1 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.531 |

| 550SG250-68 | 5.5 | 2.5 | 1 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.176 |

| 550SG250-97 | 5.5 | 2.5 | 1 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.493 |

| 550SG300-43 | 5.5 | 3 | 1 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.176 |

| 550SG300-54 | 5.5 | 3 | 1 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.723 |

| 550SG300-68 | 5.5 | 3 | 1 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.418 |

| 550SG300-97 | 5.5 | 3 | 1 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.839 |

| 550SG300-118 | 5.5 | 3 | 1 | 1 | 0.63 | 2.25 | 0.7684 | 0.5 | 0.105 | 0.1242 | 5.867 |

| 600SG162-33 | 6 | 1.6 | 1.25 | 1 | 0.63 | 2.25 | 0.5000 | 0 | 0.105 | 0.0346 | 1.291 |

| 600SG162-43 | 6 | 1.6 | 1.25 | 1 | 0.63 | 2.25 | 0.5000 | 0 | 0.105 | 0.0451 | 1.674 |

| 600SG200-33 | 6 | 2 | 1.25 | 1 | 0.63 | 2.25 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.497 |

| 600SG200-43 | 6 | 2 | 1.25 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.946 |

| 600SG200-54 | 6 | 2 | 1.25 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.435 |

| 600SG200-68 | 6 | 2 | 1.25 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.054 |

| 600SG200-97 | 6 | 2 | 1.25 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.320 |

| 600SG250-33 | 6 | 2.5 | 1.25 | 1 | 0.63 | 2.25 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.615 |

| 600SG250-43 | 6 | 2.5 | 1.25 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.100 |

| 600SG250-54 | 6 | 2.5 | 1.25 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.627 |

| 600SG250-68 | 6 | 2.5 | 1.25 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.297 |

| 600SG250-97 | 6 | 2.5 | 1.25 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.666 |

| 600SG300-43 | 6 | 3 | 1.25 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.253 |

| 600SG300-54 | 6 | 3 | 1.25 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.820 |

| 600SG300-68 | 6 | 3 | 1.25 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.540 |

| 600SG300-97 | 6 | 3 | 1.25 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 5.012 |

| 600SG300-118 | 6 | 3 | 1.25 | 1 | 0.63 | 2.25 | 0.7684 | 0.5 | 0.105 | 0.1242 | 6.078 |

| 800SG162-33 | 8 | 1.6 | 2.25 | 1 | 0.63 | 2.25 | 0.5000 | 0 | 0.105 | 0.0346 | 1.526 |

| 800SG162-43 | 8 | 1.6 | 2.25 | 1 | 0.63 | 2.25 | 0.5000 | 0 | 0.105 | 0.0451 | 1.981 |

| 800SG200-33 | 8 | 2 | 2.25 | 1 | 0.63 | 2.25 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.733 |

| 800SG200-43 | 8 | 2 | 2.25 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.253 |

| 800SG200-54 | 8 | 2 | 2.25 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.820 |

| 800SG200-68 | 8 | 2 | 2.25 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.540 |

| 800SG200-97 | 8 | 2 | 2.25 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 5.012 |

| 800SG250-33 | 8 | 2.5 | 2.25 | 1 | 0.63 | 2.25 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.851 |

| 800SG250-43 | 8 | 2.5 | 2.25 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.406 |

| 800SG250-54 | 8 | 2.5 | 2.25 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 3.012 |

| 800SG250-68 | 8 | 2.5 | 2.25 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.782 |

| 800SG250-97 | 8 | 2.5 | 2.25 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 5.358 |

| 800SG300-43 | 8 | 3 | 2.25 | 1 | 0.63 | 2.25 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.560 |

| 800SG300-54 | 8 | 3 | 2.25 | 1 | 0.63 | 2.25 | 0.6332 | 0.5 | 0.105 | 0.0566 | 3.205 |

| 800SG300-68 | 8 | 3 | 2.25 | 1 | 0.63 | 2.25 | 0.6626 | 0.5 | 0.105 | 0.0713 | 4.025 |

| 800SG300-97 | 8 | 3 | 2.25 | 1 | 0.63 | 2.25 | 0.7234 | 0.5 | 0.105 | 0.1017 | 5.704 |

| 800SG300-118 | 8 | 3 | 2.25 | 1 | 0.63 | 2.25 | 0.7684 | 0.5 | 0.105 | 0.1242 | 6.922 |

Notes:

- Section properties and capacities are calculated in accordance with AISI S100-16 Specification.

- Tabulated gross properties are based on the full-unreduced cross section of the studs, away from punchouts.

- Effective section properties incorporate the strength increase from the cold-work of forming as applicable per AISI S100-16 Spec, Sec. A3.3.2 (3).

- Net effective section properties are calculated at a cross section through the punchout.

- Allowable moment is the lesser of Mal and Mad. Stud distortional buckling is based on an assumed kΦ = 0.

- For deflection calculations, use the effective moment of inertia.

- The effective moment of inertia for deflection is calculated at a stress which results in a section modulus such that the stress times the section modulus at that stress is equal to the allowable moment. AISI S100-16 Specification Procedure I for serviceability determination has been used.

| SigmaStud® Section Properties | ||||||||||||||||||||||

| Section (All 50 ksi) |

Gross Properties | Torsional Properties | Effective Properties | |||||||||||||||||||

| Area | Ix | Sx | Rx | Iy | Ry | Jx1000 | Cw | Xo | m | Ro | ß | Ae(net) | Ixe | Sxe | Sxe(net) | Mal | Mal(net) | Mad | Mad(net) | Va | Va(net) | |

| (in2) | (in4) | (in3) | (in) | (in4) | (in) | (in4) | (in6) | (in) | (in) | (in) | (in2) | (in4) | (in3) | (in3) | (in-k) | (in-k) | (in-k) | (in-k) | (lb) | (lb) | ||

| 350SG200-33 | 0.317 | 0.630 | 0.360 | 1.410 | 0.194 | 0.782 | 0.126 | 0.718 | -1.975 | 1.178 | 2.549 | 0.400 | 0.201 | 0.615 | 0.310 | 0.283 | 9.295 | 8.479 | 8.570 | 8.332 | 1144 | 527 |

| 350SG200-43 | 0.411 | 0.810 | 0.463 | 1.404 | 0.249 | 0.779 | 0.279 | 0.929 | -1.969 | 1.176 | 2.541 | 0.399 | 0.293 | 0.810 | 0.430 | 0.406 | 12.878 | 12.161 | 12.176 | 11.825 | 2141 | 747 |

| 350SG200-54 | 0.514 | 1.003 | 0.573 | 1.397 | 0.309 | 0.775 | 0.549 | 1.158 | -1.963 | 1.173 | 2.531 | 0.398 | 0.384 | 1.003 | 0.550 | 0.530 | 16.470 | 15.871 | 16.295 | 15.825 | 3371 | 925 |

| 350SG200-68 | 0.644 | 1.241 | 0.709 | 1.388 | 0.382 | 0.770 | 1.091 | 1.444 | -1.955 | 1.169 | 2.519 | 0.397 | 0.529 | 1.241 | 0.709 | 0.696 | 23.531 | 20.831 | 23.373 | 20.636 | 4208 | 900 |

| 350SG200-97 | 0.909 | 1.705 | 0.974 | 1.370 | 0.525 | 0.760 | 3.132 | 2.017 | -1.938 | 1.160 | 2.492 | 0.395 | 0.756 | 1.705 | 0.974 | 0.958 | 33.387 | 32.831 | 33.387 | 32.827 | 5886 | 850 |

| 350SG250-33 | 0.351 | 0.734 | 0.419 | 1.445 | 0.329 | 0.967 | 0.140 | 1.206 | -2.476 | 1.448 | 3.025 | 0.330 | 0.210 | 0.693 | 0.331 | 0.300 | 9.904 | 8.995 | 9.106 | 8.870 | 1144 | 527 |

| 350SG250-43 | 0.456 | 0.945 | 0.540 | 1.439 | 0.424 | 0.964 | 0.309 | 1.565 | -2.471 | 1.445 | 3.017 | 0.329 | 0.292 | 0.933 | 0.447 | 0.418 | 13.371 | 12.505 | 13.045 | 12.687 | 2141 | 747 |

| 350SG250-54 | 0.571 | 1.171 | 0.669 | 1.432 | 0.526 | 0.960 | 0.609 | 1.953 | -2.465 | 1.442 | 3.008 | 0.329 | 0.383 | 1.171 | 0.571 | 0.545 | 17.099 | 16.324 | 17.616 | 17.120 | 3371 | 925 |

| 350SG250-68 | 0.715 | 1.450 | 0.829 | 1.424 | 0.653 | 0.955 | 1.212 | 2.443 | -2.457 | 1.439 | 2.996 | 0.328 | 0.519 | 1.450 | 0.748 | 0.728 | 22.400 | 21.809 | 23.676 | 23.014 | 4208 | 900 |

| 350SG250-97 | 1.010 | 1.999 | 1.142 | 1.406 | 0.904 | 0.946 | 3.483 | 3.431 | -2.441 | 1.430 | 2.972 | 0.325 | 0.835 | 1.999 | 1.125 | 1.107 | 37.597 | 37.006 | 38.177 | 37.438 | 5886 | 850 |

| 350SG350-68 | 0.858 | 1.870 | 1.068 | 1.476 | 1.471 | 1.309 | 1.454 | 5.401 | -3.456 | 1.965 | 3.980 | 0.246 | 0.535 | 1.812 | 0.804 | 0.774 | 24.073 | 23.179 | 26.651 | 25.932 | 4208 | 900 |

| 362SG200-33 | 0.321 | 0.683 | 0.377 | 1.459 | 0.196 | 0.782 | 0.128 | 0.759 | -1.954 | 1.168 | 2.561 | 0.418 | 0.202 | 0.668 | 0.326 | 0.295 | 9.754 | 8.842 | 8.919 | 8.673 | 1102 | 544 |

| 362SG200-43 | 0.417 | 0.879 | 0.485 | 1.452 | 0.253 | 0.779 | 0.283 | 0.983 | -1.948 | 1.166 | 2.552 | 0.417 | 0.293 | 0.879 | 0.451 | 0.424 | 13.504 | 12.690 | 12.685 | 12.320 | 2141 | 802 |

| 362SG200-54 | 0.521 | 1.089 | 0.601 | 1.445 | 0.313 | 0.775 | 0.556 | 1.224 | -1.942 | 1.163 | 2.542 | 0.416 | 0.385 | 1.089 | 0.577 | 0.553 | 17.261 | 16.571 | 16.994 | 16.504 | 3372 | 994 |

| 362SG200-68 | 0.653 | 1.348 | 0.744 | 1.437 | 0.388 | 0.770 | 1.107 | 1.526 | -1.934 | 1.159 | 2.530 | 0.415 | 0.532 | 1.348 | 0.744 | 0.728 | 24.678 | 21.799 | 24.401 | 21.653 | 4375 | 1007 |

| 362SG200-97 | 0.921 | 1.854 | 1.023 | 1.419 | 0.533 | 0.761 | 3.176 | 2.130 | -1.918 | 1.150 | 2.504 | 0.413 | 0.769 | 1.854 | 1.023 | 1.007 | 35.050 | 34.514 | 35.050 | 34.509 | 6124 | 954 |

| 362SG250-33 | 0.356 | 0.795 | 0.438 | 1.495 | 0.333 | 0.968 | 0.142 | 1.277 | -2.453 | 1.437 | 3.031 | 0.345 | 0.210 | 0.751 | 0.347 | 0.313 | 10.387 | 9.375 | 9.461 | 9.217 | 1102 | 544 |

| 362SG250-43 | 0.462 | 1.024 | 0.565 | 1.489 | 0.430 | 0.964 | 0.313 | 1.656 | -2.447 | 1.435 | 3.023 | 0.344 | 0.293 | 1.011 | 0.468 | 0.435 | 14.012 | 13.038 | 13.565 | 13.194 | 2141 | 802 |

| 362SG250-54 | 0.578 | 1.269 | 0.700 | 1.482 | 0.533 | 0.961 | 0.617 | 2.066 | -2.442 | 1.432 | 3.014 | 0.344 | 0.385 | 1.269 | 0.598 | 0.569 | 17.908 | 17.031 | 18.335 | 17.821 | 3372 | 994 |

| 362SG250-68 | 0.724 | 1.573 | 0.868 | 1.474 | 0.662 | 0.956 | 1.227 | 2.583 | -2.434 | 1.428 | 3.002 | 0.342 | 0.522 | 1.573 | 0.783 | 0.761 | 23.449 | 22.775 | 24.670 | 23.982 | 4375 | 1007 |

| 362SG250-97 | 1.023 | 2.169 | 1.197 | 1.456 | 0.916 | 0.946 | 3.527 | 3.625 | -2.418 | 1.420 | 2.977 | 0.340 | 0.848 | 2.169 | 1.178 | 1.161 | 39.389 | 38.814 | 40.011 | 39.252 | 6124 | 954 |

| 362SG350-68 | 0.867 | 2.023 | 1.116 | 1.528 | 1.491 | 1.311 | 1.469 | 5.715 | -3.430 | 1.954 | 3.977 | 0.256 | 0.538 | 1.961 | 0.841 | 0.808 | 25.186 | 24.190 | 27.689 | 26.946 | 4375 | 1007 |

| 400SG200-33 | 0.334 | 0.859 | 0.429 | 1.603 | 0.204 | 0.782 | 0.133 | 0.895 | -1.894 | 1.139 | 2.602 | 0.470 | 0.202 | 0.842 | 0.373 | 0.332 | 11.168 | 9.928 | 9.971 | 9.701 | 991 | 589 |

| 400SG200-43 | 0.434 | 1.107 | 0.553 | 1.597 | 0.263 | 0.778 | 0.294 | 1.157 | -1.889 | 1.136 | 2.593 | 0.469 | 0.295 | 1.107 | 0.515 | 0.477 | 15.429 | 14.276 | 14.220 | 13.817 | 2141 | 967 |

| 400SG200-54 | 0.542 | 1.371 | 0.686 | 1.590 | 0.325 | 0.775 | 0.579 | 1.440 | -1.883 | 1.133 | 2.583 | 0.469 | 0.389 | 1.371 | 0.658 | 0.624 | 19.693 | 18.673 | 19.109 | 18.563 | 3372 | 1201 |

| 400SG200-68 | 0.680 | 1.700 | 0.850 | 1.581 | 0.403 | 0.770 | 1.152 | 1.794 | -1.875 | 1.129 | 2.571 | 0.468 | 0.540 | 1.700 | 0.850 | 0.825 | 28.202 | 24.708 | 27.517 | 24.756 | 4876 | 1360 |

| 400SG200-97 | 0.959 | 2.344 | 1.172 | 1.563 | 0.555 | 0.760 | 3.308 | 2.498 | -1.858 | 1.121 | 2.544 | 0.467 | 0.806 | 2.344 | 1.172 | 1.158 | 40.162 | 34.664 | 40.162 | 34.659 | 6839 | 1299 |

| 400SG250-33 | 0.369 | 0.995 | 0.497 | 1.643 | 0.346 | 0.969 | 0.147 | 1.506 | -2.386 | 1.407 | 3.055 | 0.390 | 0.211 | 0.944 | 0.397 | 0.351 | 11.873 | 10.514 | 10.530 | 10.264 | 991 | 589 |

| 400SG250-43 | 0.479 | 1.283 | 0.641 | 1.637 | 0.446 | 0.965 | 0.325 | 1.951 | -2.381 | 1.404 | 3.046 | 0.389 | 0.294 | 1.268 | 0.534 | 0.489 | 15.981 | 14.635 | 15.133 | 14.726 | 2141 | 967 |

| 400SG250-54 | 0.599 | 1.591 | 0.796 | 1.630 | 0.554 | 0.962 | 0.640 | 2.432 | -2.375 | 1.401 | 3.037 | 0.388 | 0.388 | 1.591 | 0.681 | 0.640 | 20.397 | 19.150 | 20.506 | 19.938 | 3372 | 1201 |

| 400SG250-68 | 0.751 | 1.975 | 0.987 | 1.622 | 0.688 | 0.957 | 1.273 | 3.038 | -2.368 | 1.398 | 3.025 | 0.387 | 0.530 | 1.975 | 0.891 | 0.858 | 26.669 | 25.675 | 27.679 | 26.913 | 4876 | 1360 |

| 400SG250-97 | 1.061 | 2.730 | 1.365 | 1.604 | 0.953 | 0.948 | 3.658 | 4.255 | -2.352 | 1.390 | 3.000 | 0.386 | 0.908 | 2.730 | 1.343 | 1.351 | 44.884 | 40.448 | 45.635 | 40.443 | 6839 | 1299 |

| 400SG350-68 | 0.894 | 2.525 | 1.263 | 1.681 | 1.547 | 1.316 | 1.514 | 6.736 | -3.354 | 1.922 | 3.976 | 0.288 | 0.545 | 2.447 | 0.955 | 0.909 | 28.602 | 27.223 | 30.818 | 30.002 | 4876 | 1360 |

| 400SG350-97 | 1.265 | 3.503 | 1.751 | 1.664 | 2.158 | 1.306 | 4.360 | 9.488 | -3.339 | 1.915 | 3.953 | 0.286 | 0.917 | 3.483 | 1.502 | 1.473 | 44.961 | 44.092 | 49.104 | 47.809 | 6839 | 1299 |

| 400SG350-118 | 1.533 | 4.184 | 2.092 | 1.652 | 2.587 | 1.299 | 7.855 | 11.458 | -3.328 | 1.909 | 3.936 | 0.285 | 1.235 | 4.184 | 1.980 | 1.955 | 59.268 | 58.533 | 62.640 | 61.275 | 8235 | 1256 |

| 550SG162-33 | 0.362 | 1.522 | 0.554 | 2.051 | 0.096 | 0.514 | 0.144 | 0.864 | -0.203 | 0.495 | 2.124 | 0.991 | 0.261 | 1.522 | 0.498 | 0.492 | 14.920 | 14.716 | 11.731 | 11.263 | 996 | 586 |

| 550SG162-43 | 0.469 | 1.963 | 0.714 | 2.045 | 0.122 | 0.510 | 0.318 | 1.097 | -0.191 | 0.504 | 2.116 | 0.992 | 0.364 | 1.963 | 0.663 | 0.655 | 19.843 | 19.611 | 16.926 | 16.198 | 2141 | 953 |

| 550SG200-33 | 0.423 | 1.882 | 0.684 | 2.110 | 0.175 | 0.643 | 0.169 | 1.783 | -0.716 | 0.160 | 2.319 | 0.905 | 0.315 | 1.858 | 0.609 | 0.602 | 18.234 | 18.016 | 14.840 | 14.464 | 996 | 586 |

| 550SG200-43 | 0.549 | 2.432 | 0.884 | 2.104 | 0.225 | 0.640 | 0.372 | 2.294 | -0.708 | 0.165 | 2.310 | 0.906 | 0.447 | 2.432 | 0.833 | 0.826 | 24.934 | 24.718 | 21.359 | 20.787 | 2141 | 953 |

| 550SG200-54 | 0.687 | 3.023 | 1.099 | 2.097 | 0.278 | 0.636 | 0.734 | 2.838 | -0.700 | 0.172 | 2.301 | 0.907 | 0.577 | 3.023 | 1.058 | 1.050 | 31.665 | 31.425 | 28.982 | 28.186 | 3372 | 1176 |

| 550SG200-68 | 0.862 | 3.761 | 1.368 | 2.089 | 0.344 | 0.631 | 1.460 | 3.510 | -0.689 | 0.180 | 2.289 | 0.909 | 0.755 | 3.761 | 1.368 | 1.361 | 45.387 | 45.149 | 42.130 | 40.928 | 4793 | 1298 |

| 550SG200-97 | 1.219 | 5.229 | 1.901 | 2.072 | 0.471 | 0.622 | 4.201 | 4.816 | -0.667 | 0.197 | 2.263 | 0.913 | 1.066 | 5.229 | 1.901 | 1.891 | 65.164 | 64.815 | 65.164 | 64.762 | 6657 | 1207 |

| 550SG250-33 | 0.457 | 2.140 | 0.778 | 2.163 | 0.302 | 0.813 | 0.182 | 2.936 | -1.157 | 0.109 | 2.584 | 0.800 | 0.324 | 2.055 | 0.644 | 0.634 | 19.272 | 18.975 | 15.414 | 15.050 | 996 | 586 |

| 550SG250-43 | 0.594 | 2.767 | 1.006 | 2.158 | 0.389 | 0.809 | 0.403 | 3.788 | -1.149 | 0.104 | 2.575 | 0.801 | 0.446 | 2.750 | 0.860 | 0.848 | 25.735 | 25.384 | 22.319 | 21.755 | 2141 | 953 |

| 550SG250-54 | 0.744 | 3.442 | 1.252 | 2.151 | 0.483 | 0.806 | 0.794 | 4.701 | -1.141 | 0.098 | 2.565 | 0.802 | 0.576 | 3.442 | 1.092 | 1.078 | 32.686 | 32.274 | 30.488 | 29.686 | 3372 | 1176 |

| 550SG250-68 | 0.933 | 4.286 | 1.559 | 2.143 | 0.599 | 0.801 | 1.581 | 5.835 | -1.131 | 0.090 | 2.552 | 0.804 | 0.745 | 4.286 | 1.418 | 1.403 | 42.443 | 42.007 | 41.569 | 40.458 | 4793 | 1298 |

| 550SG250-97 | 1.320 | 5.970 | 2.171 | 2.126 | 0.826 | 0.791 | 4.552 | 8.069 | -1.108 | 0.073 | 2.525 | 0.807 | 1.143 | 5.970 | 2.133 | 2.121 | 71.321 | 70.907 | 71.151 | 69.241 | 6657 | 1207 |

| 550SG300-43 | 0.639 | 3.103 | 1.128 | 2.203 | 0.622 | 0.987 | 0.434 | 5.742 | -1.597 | 0.369 | 2.894 | 0.695 | 0.443 | 2.993 | 0.876 | 0.859 | 26.214 | 25.729 | 23.034 | 22.484 | 2141 | 953 |

| 550SG300-54 | 0.800 | 3.861 | 1.404 | 2.197 | 0.773 | 0.983 | 0.855 | 7.139 | -1.589 | 0.363 | 2.884 | 0.696 | 0.580 | 3.736 | 1.128 | 1.110 | 33.781 | 33.222 | 31.625 | 30.830 | 3372 | 1176 |

| 550SG300-68 | 1.004 | 4.812 | 1.750 | 2.189 | 0.960 | 0.978 | 1.702 | 8.883 | -1.579 | 0.355 | 2.870 | 0.697 | 0.756 | 4.765 | 1.476 | 1.455 | 44.180 | 43.572 | 43.406 | 42.278 | 4793 | 1298 |

| 550SG300-97 | 1.422 | 6.711 | 2.440 | 2.172 | 1.332 | 0.968 | 4.902 | 12.348 | -1.557 | 0.340 | 2.843 | 0.700 | 1.187 | 6.711 | 2.310 | 2.293 | 69.159 | 68.650 | 69.483 | 67.704 | 6657 | 1207 |

| 550SG300-118 | 1.724 | 8.048 | 2.927 | 2.161 | 1.590 | 0.960 | 8.837 | 14.766 | -1.541 | 0.328 | 2.822 | 0.702 | 1.462 | 8.048 | 2.812 | 2.793 | 93.863 | 93.245 | 96.698 | 94.218 | 7956 | 1142 |

| 600SG162-33 | 0.379 | 1.854 | 0.618 | 2.211 | 0.104 | 0.523 | 0.151 | 1.090 | -0.234 | 0.432 | 2.284 | 0.990 | 0.279 | 1.854 | 0.558 | 0.551 | 16.702 | 16.505 | 12.720 | 12.230 | 878 | 634 |

| 600SG162-43 | 0.492 | 2.392 | 0.797 | 2.205 | 0.133 | 0.519 | 0.334 | 1.386 | -0.222 | 0.441 | 2.276 | 0.990 | 0.386 | 2.392 | 0.741 | 0.734 | 22.192 | 21.969 | 18.413 | 17.644 | 1959 | 1073 |

| 600SG200-33 | 0.440 | 2.291 | 0.764 | 2.282 | 0.187 | 0.653 | 0.176 | 2.203 | -0.744 | 0.097 | 2.487 | 0.910 | 0.333 | 2.266 | 0.682 | 0.675 | 20.417 | 20.203 | 16.201 | 15.800 | 878 | 634 |

| 600SG200-43 | 0.572 | 2.962 | 0.987 | 2.276 | 0.241 | 0.650 | 0.388 | 2.837 | -0.737 | 0.102 | 2.479 | 0.912 | 0.470 | 2.962 | 0.931 | 0.924 | 27.880 | 27.673 | 23.374 | 22.760 | 1959 | 1073 |

| 600SG200-54 | 0.715 | 3.683 | 1.228 | 2.269 | 0.299 | 0.646 | 0.764 | 3.513 | -0.729 | 0.108 | 2.469 | 0.913 | 0.605 | 3.683 | 1.182 | 1.174 | 35.379 | 35.150 | 31.797 | 30.937 | 3372 | 1452 |

| 600SG200-68 | 0.898 | 4.586 | 1.529 | 2.261 | 0.370 | 0.642 | 1.521 | 4.350 | -0.719 | 0.116 | 2.457 | 0.914 | 0.791 | 4.586 | 1.529 | 1.522 | 50.735 | 50.518 | 46.332 | 45.025 | 5352 | 1797 |

| 600SG200-97 | 1.269 | 6.386 | 2.129 | 2.243 | 0.508 | 0.633 | 4.376 | 5.980 | -0.697 | 0.133 | 2.432 | 0.918 | 1.117 | 6.386 | 2.129 | 2.119 | 72.948 | 72.629 | 72.948 | 72.305 | 7610 | 1726 |

| 600SG250-33 | 0.475 | 2.599 | 0.866 | 2.340 | 0.320 | 0.822 | 0.189 | 3.590 | -1.180 | 0.170 | 2.747 | 0.815 | 0.341 | 2.501 | 0.720 | 0.710 | 21.563 | 21.269 | 16.810 | 16.422 | 878 | 634 |

| 600SG250-43 | 0.617 | 3.362 | 1.121 | 2.334 | 0.413 | 0.818 | 0.418 | 4.633 | -1.173 | 0.165 | 2.737 | 0.816 | 0.469 | 3.345 | 0.961 | 0.949 | 28.760 | 28.412 | 24.389 | 23.785 | 1959 | 1073 |

| 600SG250-54 | 0.772 | 4.183 | 1.394 | 2.328 | 0.513 | 0.815 | 0.824 | 5.752 | -1.165 | 0.160 | 2.728 | 0.818 | 0.604 | 4.183 | 1.219 | 1.206 | 36.501 | 36.093 | 33.384 | 32.520 | 3372 | 1452 |

| 600SG250-68 | 0.969 | 5.213 | 1.738 | 2.320 | 0.636 | 0.810 | 1.642 | 7.145 | -1.155 | 0.152 | 2.715 | 0.819 | 0.780 | 5.213 | 1.582 | 1.567 | 47.351 | 46.922 | 45.633 | 44.428 | 5352 | 1797 |

| 600SG250-97 | 1.371 | 7.270 | 2.423 | 2.303 | 0.879 | 0.800 | 4.727 | 9.893 | -1.133 | 0.137 | 2.688 | 0.822 | 1.195 | 7.270 | 2.381 | 2.369 | 79.592 | 79.202 | 78.437 | 76.343 | 7610 | 1726 |

| 600SG300-43 | 0.662 | 3.761 | 1.254 | 2.384 | 0.655 | 0.995 | 0.449 | 6.972 | -1.616 | 0.429 | 3.047 | 0.719 | 0.466 | 3.639 | 0.979 | 0.962 | 29.297 | 28.809 | 25.131 | 24.543 | 1959 | 1073 |

| 600SG300-54 | 0.829 | 4.683 | 1.561 | 2.377 | 0.814 | 0.991 | 0.885 | 8.670 | -1.608 | 0.424 | 3.036 | 0.720 | 0.608 | 4.539 | 1.260 | 1.241 | 37.713 | 37.153 | 34.564 | 33.711 | 3372 | 1452 |

| 600SG300-68 | 1.040 | 5.840 | 1.947 | 2.369 | 1.012 | 0.986 | 1.763 | 10.793 | -1.598 | 0.417 | 3.023 | 0.721 | 0.791 | 5.790 | 1.646 | 1.625 | 49.272 | 48.663 | 47.543 | 46.327 | 5352 | 1797 |

| 600SG300-97 | 1.473 | 8.155 | 2.718 | 2.353 | 1.404 | 0.976 | 5.078 | 15.015 | -1.577 | 0.402 | 2.996 | 0.723 | 1.238 | 8.155 | 2.572 | 2.556 | 77.021 | 76.525 | 76.434 | 74.491 | 7610 | 1726 |

| 600SG300-118 | 1.786 | 9.789 | 3.263 | 2.341 | 1.678 | 0.969 | 9.154 | 17.967 | -1.562 | 0.391 | 2.976 | 0.725 | 1.525 | 9.789 | 3.134 | 3.116 | 104.620 | 104.024 | 106.616 | 103.892 | 9118 | 1649 |

| 800SG162-33 | 0.448 | 3.631 | 0.908 | 2.845 | 0.130 | 0.538 | 0.179 | 2.193 | -0.302 | 0.261 | 2.912 | 0.989 | 0.298 | 3.631 | 0.754 | 0.744 | 22.576 | 22.270 | 16.445 | 15.895 | 595 | 595 |

| 800SG162-43 | 0.582 | 4.691 | 1.173 | 2.839 | 0.166 | 0.534 | 0.395 | 2.796 | -0.292 | 0.269 | 2.903 | 0.990 | 0.439 | 4.691 | 1.056 | 1.047 | 31.604 | 31.335 | 24.107 | 23.217 | 1324 | 1268 |

| 800SG200-33 | 0.509 | 4.453 | 1.113 | 2.957 | 0.230 | 0.672 | 0.203 | 4.278 | -0.791 | 0.064 | 3.134 | 0.936 | 0.352 | 4.431 | 0.930 | 0.919 | 27.843 | 27.525 | 21.591 | 21.107 | 595 | 595 |

| 800SG200-43 | 0.662 | 5.765 | 1.441 | 2.951 | 0.296 | 0.669 | 0.449 | 5.516 | -0.784 | 0.059 | 3.126 | 0.937 | 0.522 | 5.765 | 1.325 | 1.317 | 39.673 | 39.425 | 31.423 | 30.667 | 1324 | 1268 |

| 800SG200-54 | 0.829 | 7.181 | 1.795 | 2.944 | 0.367 | 0.666 | 0.885 | 6.840 | -0.777 | 0.054 | 3.117 | 0.938 | 0.701 | 7.181 | 1.731 | 1.724 | 51.819 | 51.620 | 43.141 | 42.055 | 2632 | 1994 |

| 800SG200-68 | 1.040 | 8.960 | 2.240 | 2.935 | 0.455 | 0.662 | 1.763 | 8.484 | -0.767 | 0.047 | 3.105 | 0.939 | 0.933 | 8.960 | 2.240 | 2.235 | 74.340 | 74.180 | 63.400 | 61.713 | 5300 | 3156 |

| 800SG200-97 | 1.473 | 12.530 | 3.133 | 2.917 | 0.629 | 0.653 | 5.078 | 11.713 | -0.748 | 0.033 | 3.081 | 0.941 | 1.320 | 12.530 | 3.133 | 3.126 | 107.352 | 107.117 | 104.064 | 101.327 | 10888 | 4452 |

| 800SG250-33 | 0.544 | 5.002 | 1.250 | 3.033 | 0.382 | 0.838 | 0.217 | 6.837 | -1.202 | 0.321 | 3.368 | 0.873 | 0.360 | 4.856 | 0.980 | 0.967 | 29.352 | 28.942 | 22.427 | 21.953 | 595 | 595 |

| 800SG250-43 | 0.707 | 6.478 | 1.620 | 3.027 | 0.493 | 0.835 | 0.479 | 8.833 | -1.196 | 0.317 | 3.360 | 0.873 | 0.522 | 6.478 | 1.363 | 1.349 | 40.806 | 40.395 | 32.761 | 32.012 | 1324 | 1268 |

| 800SG250-54 | 0.885 | 8.074 | 2.019 | 3.020 | 0.612 | 0.832 | 0.945 | 10.975 | -1.189 | 0.312 | 3.350 | 0.874 | 0.701 | 8.074 | 1.782 | 1.769 | 53.363 | 52.965 | 45.165 | 44.076 | 2632 | 1994 |

| 800SG250-68 | 1.111 | 10.081 | 2.520 | 3.012 | 0.761 | 0.827 | 1.883 | 13.649 | -1.179 | 0.305 | 3.339 | 0.875 | 0.923 | 10.081 | 2.304 | 2.291 | 68.996 | 68.586 | 62.282 | 60.729 | 5300 | 3156 |

| 800SG250-97 | 1.575 | 14.116 | 3.529 | 2.994 | 1.055 | 0.818 | 5.428 | 18.950 | -1.160 | 0.292 | 3.314 | 0.877 | 1.402 | 14.116 | 3.466 | 3.456 | 115.861 | 115.535 | 108.627 | 105.815 | 10888 | 4452 |

| 800SG300-43 | 0.752 | 7.192 | 1.798 | 3.092 | 0.767 | 1.010 | 0.510 | 13.119 | -1.617 | 0.573 | 3.633 | 0.802 | 0.518 | 7.028 | 1.387 | 1.368 | 41.519 | 40.945 | 33.663 | 32.933 | 1324 | 1268 |

| 800SG300-54 | 0.942 | 8.967 | 2.242 | 3.086 | 0.954 | 1.006 | 1.006 | 16.324 | -1.610 | 0.568 | 3.623 | 0.802 | 0.705 | 8.804 | 1.839 | 1.820 | 55.068 | 54.497 | 46.575 | 45.502 | 2632 | 1994 |

| 800SG300-68 | 1.183 | 11.202 | 2.800 | 3.078 | 1.187 | 1.002 | 2.004 | 20.337 | -1.601 | 0.562 | 3.611 | 0.803 | 0.934 | 11.176 | 2.394 | 2.373 | 71.673 | 71.061 | 64.531 | 62.977 | 5300 | 3156 |

| 800SG300-97 | 1.676 | 15.702 | 3.926 | 3.061 | 1.651 | 0.993 | 5.779 | 28.342 | -1.582 | 0.549 | 3.586 | 0.805 | 1.441 | 15.702 | 3.719 | 3.703 | 111.337 | 110.877 | 105.253 | 102.673 | 10888 | 4452 |

| 800SG300-118 | 2.034 | 18.902 | 4.725 | 3.048 | 1.976 | 0.986 | 10.426 | 33.962 | -1.568 | 0.540 | 3.567 | 0.807 | 1.775 | 18.902 | 4.539 | 4.523 | 151.547 | 151.009 | 147.942 | 144.251 | 13768 | 4546 |

Notes:

- Section properties and capacities are calculated in accordance with AISI S100-16 Spec, “North American Specification for the Design of Cold-Formed Steel Structural Members”.

- Tabulated gross properties are based on the full-unreduced cross section of the studs, away from punchouts.

Effective section properties incorporate the strength increase from the cold-work of forming as applicable per AISI S100-16 Spec, Sec. A3.3.2 (3). - Allowable moment is the lesser of Mal and Mad. Stud distortional buckling is based on an assumed kΦ = 0.

- For deflection calculations, use the effective moment of inertia.

- The effective moment of inertia for deflection is calculated at a stress which results in a section modulus such that the stress times the section modulus at that stress is equal to the allowable moment. AISI S100-16 Procedure I for serviceability determination has been used.

Follow us on Social Media