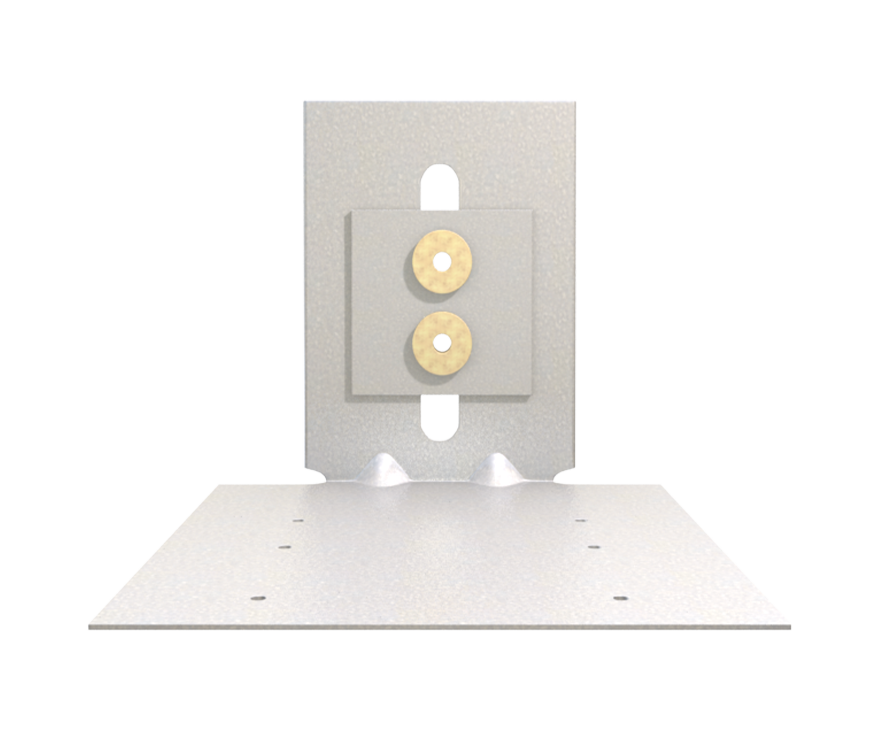

VertiClip® SLF

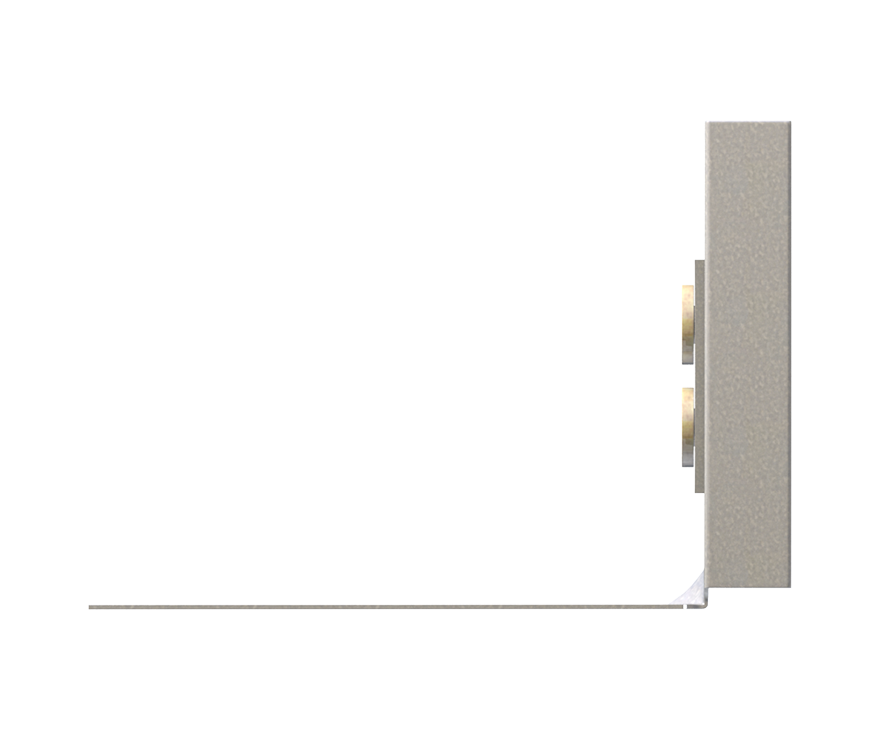

This vertical deflection clip is used to connect exterior cold-formed steel curtain wall studs to the slab, bypassing the primary structure, when the stud web is inaccessible. Install with up to a 1½” of offset between the stud and primary structure.

VertiClip SLF allows up to 1½” of vertical deflection (¾”up and ¾” down). TSN’s patented Step Bushing Technology provides an anti-friction and anti-seizure connection between the clip and the stud web surface.

Features

- VertiClip SLF for use with 2” stud flanges is made as a custom part. Load-rated positive mechanical attachment at each stud

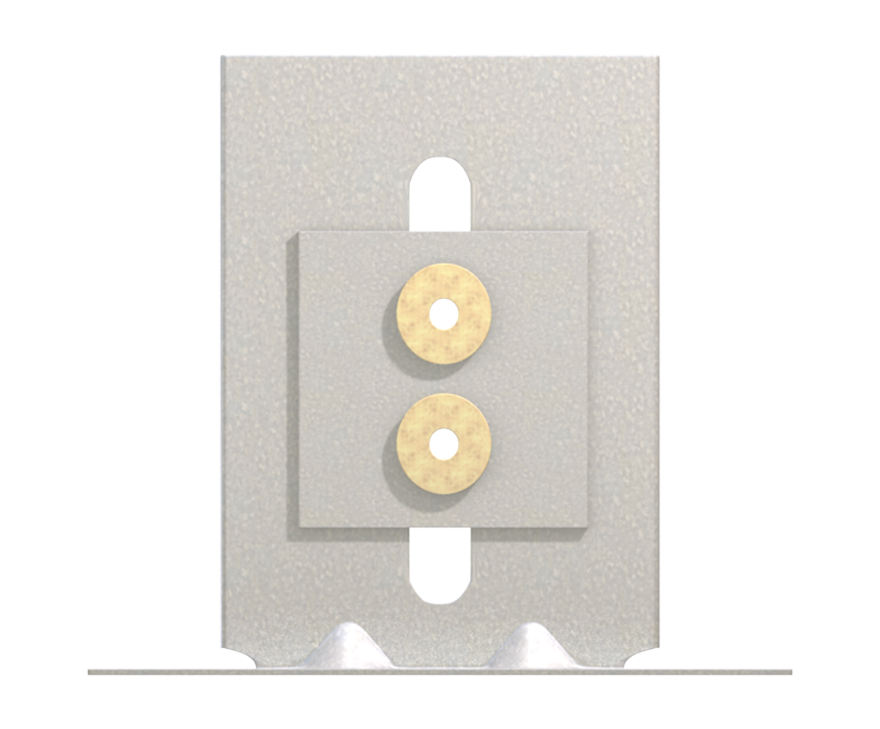

- Patented Step Bushing Technology provides friction-free motion for smooth vertical deflection

- Eliminates loose friction-held assemblies, heavy deep-leg track, & top row of wall bridging/strapping

- Load-rated #12 screws provided for vertical deflection connection to stud web

- Manufactured with certified, 50ksi, 68 mil, G90 cold-formed steel

Order Information

Qty/Box

VertiClip SLF162

Lbs/Box

VertiClip SLF162

Qty/Skid

VertiClip SLF162

Lbs/Skid

VertiClip SLF162

Nomenclature:

VertiClip SLF is available in one size for all stud depths with 1⅝” flanges.

* VertiClip SLF for use with 2” stud flanges can be made as a custom part.

Material Composition

Catalogs

|

|

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

US Patents #8,511,032

VertiClip SLF Downloads

VertiClip® SLF Applications

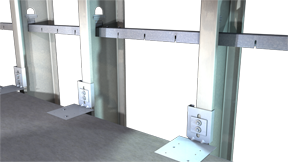

The attachment of VertiClip SLF to the primary structure may be made with PAFs, screw/bolt anchors or weld and is dependent upon the base material (steel or concrete) and the design configuration.

With TSN’s BridgeBar® & BridgeClip® installed within 12” from the clip

With flat strap bracing on the outer flange of studs to resist torsional effects

Installation Instructions

- Attach VertiClip® SLF to structure with required fastener quantity, spacing and edge distance.

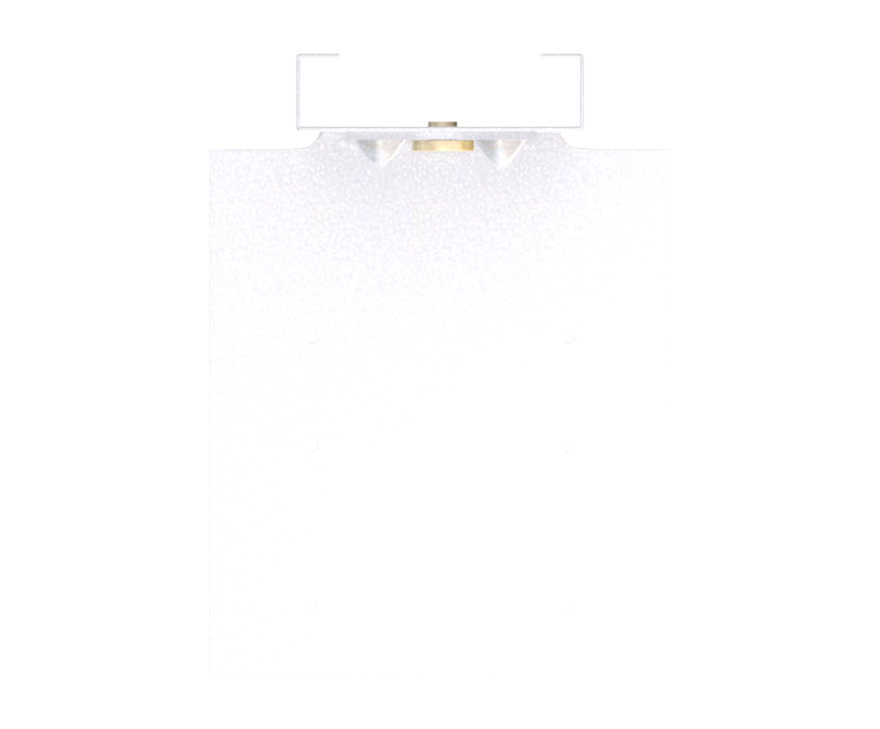

- Ensure that the stud’s return bend is fully seated in the clip.

- Fasten SLF to stud with provided screws through step bushings.

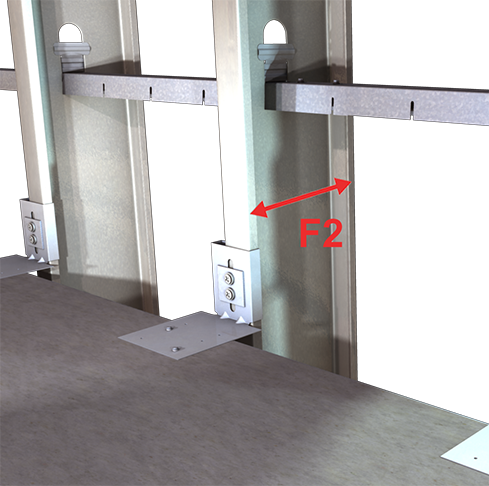

Recommended Allowable Load (lbs): F2

Notes:

- Stud web crippling should be checked. Use 3½” bearing length and “Interior Reaction – one Flange”, Condition 2, for the web crippling calculations except at end of stud use”End Reaction – one Flange”, Condition 1.

- Align rows of wall bridging so that one row of bridging falls within 12″ from VertiClip SLF OR use one flat strap bracing on outer flange of studs to resist torsional effects.

- Allowable loads have not been increased for wind, seismic, or other factors.

- #12 screws are provided with each Step Bushing.

- VertiClip SLF allows up to 1½” of vertical deflection (¾” up and ¾” down)

- For LRFD Design Strengths contact TSN technical services.

Load Direction

Follow us on Social Media