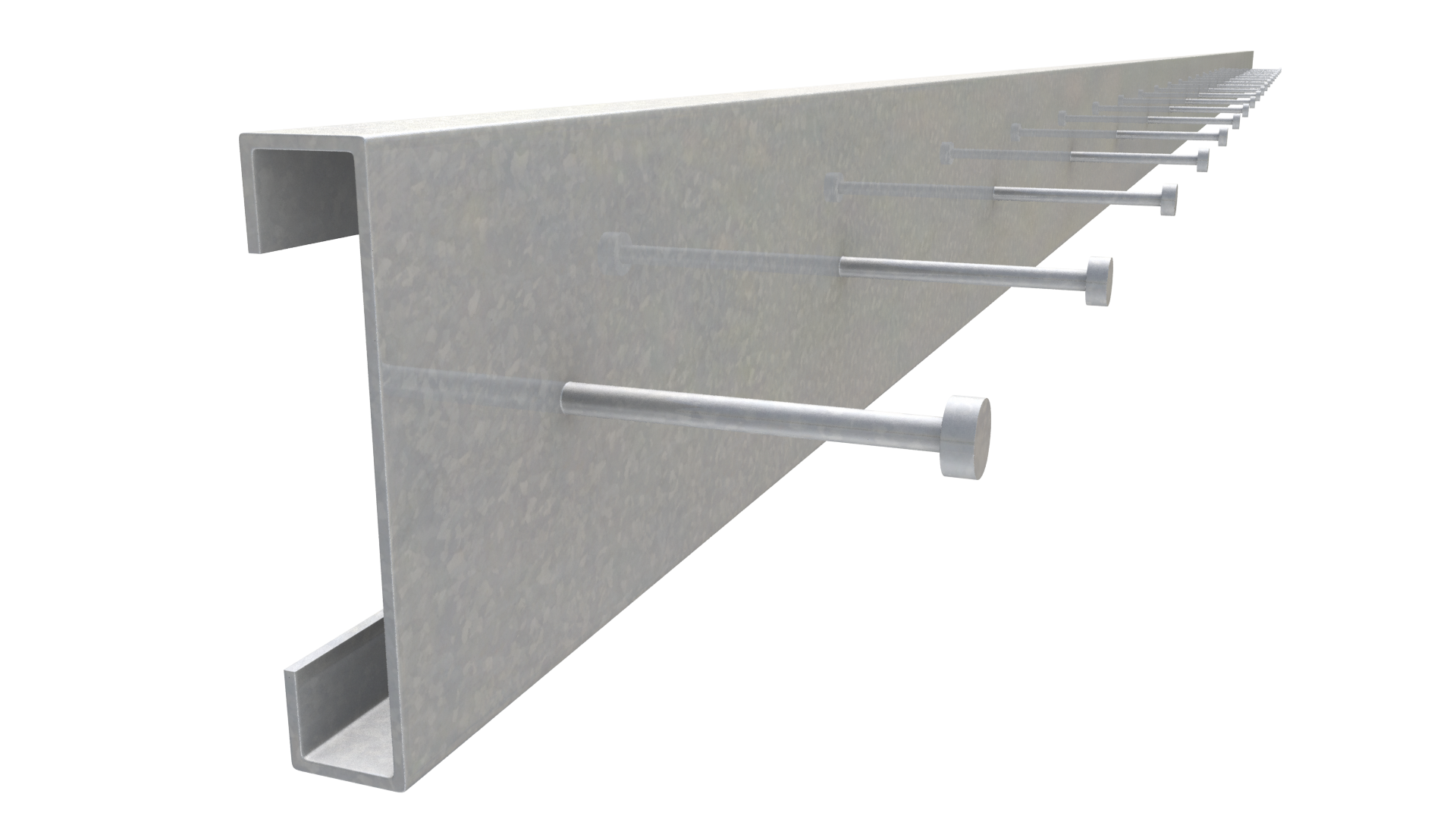

DriftTrak® Headed Stud

Features

- DTSLB is ICC-ES Approved, report #ESR-2049

- Grooves in 1” leg pass over fastener heads

- DTSLB-HD clips without notches for greater F2 outward load capacity.

- Locking Angle DT-LA is available to lock the horizontal movement of the wall panel after installation for cases of no drift requirements.

- DriftTrak is available in 12’ lengths.

- Load-rated positive mechanical attachment at each stud

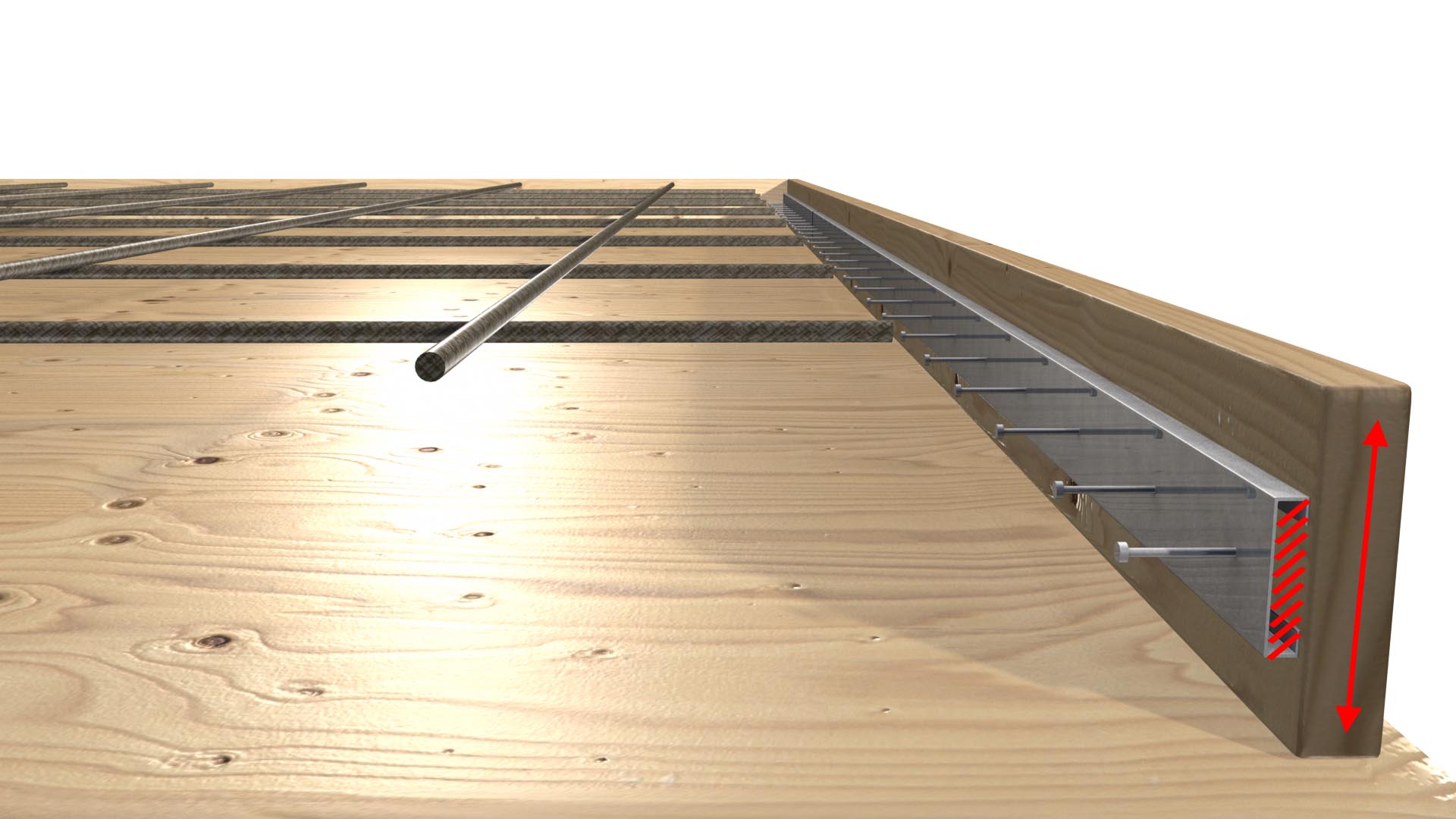

- Patented Step Bushing Technology provides friction-free motion for smooth vertical deflection

- Eliminates loose friction-held assemblies, heavy deep-leg track, & top row of wall bridging/strapping

- Load-rated #12 screws provided for vertical deflection connection to stud web

- Track DTLB, & DTSLB-HD manufactured with certified, 50ksi, 97mil, G90 cold-formed steel

- DTSLB manufactured with certified, 50ksi, 68mil, G90 cold-formed steel

Order Information

Qty/Box

DTSLB362/400

DTSLB362/400-HD

DTSLB600

DTSLB600-HD

DTSLB800

DTSLB800-HD

DTLB600

DTLB600-HD

DTLB800

DTLB800-HD

DT-LA (Locking Angle)

DriftTrak® DTH-10ft

DriftTrak® DTH-12ft

Lbs/Box

DTSLB362/400

DTSLB362/400-HD

DTSLB600

DTSLB600-HD

DTSLB800

DTSLB800-HD

DTLB600

DTLB600-HD

DTLB800

DTLB800-HD

DT-LA (Locking Angle)

DriftTrak® DTH-10ft

DriftTrak® DTH-12ft

Qty/Skid

DTSLB362/400

DTSLB362/400-HD

DTSLB600

DTSLB600-HD

DTSLB800

DTSLB800-HD

DTLB600

DTLB600-HD

DTLB800

DTLB800-HD

DT-LA (Locking Angle)

DriftTrak® DTH-10ft

DriftTrak® DTH-12ft

Lbs/Skid

DTSLB362/400

DTSLB362/400-HD

DTSLB600

DTSLB600-HD

DTSLB800

DTSLB800-HD

DTLB600

DTLB600-HD

DTLB800

DTLB800-HD

DT-LA (Locking Angle)

DriftTrak® DTH-10ft

DriftTrak® DTH-12ft

Nomenclature: The DriftTrack Headed Stud comes in 10′ and 12′ lengths. To specify DriftTrak, list “DTH,” followed by the length. The assembly requires the member (DTH-10 or DTH-12) and the connector (DTSLB/DTLB). DTSLB is classified by multiplying stud depth by 100, followed by “HD,” based on F2 strength required. Refer to load tables.*

Example:6″ stud depth, with an outward load (F2) of 1,000 lbs

Designate: DTH-12 & DTSLB600-HD

* Clips (DTSLB/DTLB) and track (DTH-10 or DTH-12) are ordered/sold separately.

** Notches are standard in DriftTrak DTSLB. For greater F2 outward load capacity, use DTSLB-HD clips without notches. Refer to Allowable Load Table.

Material Composition

Track Material: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 97mil minimum thickness (12 gauge, 0.1017” design thickness) with ASTM A653/A653M G60 (Z180) hot dipped galvanized coating.

Headed Stud Material: ASTM A29/A108, Grades 1010 through 1020 or equivalent, 45ksi (310MPa) minimum yield strength, 55ksi (380MPa) minimum tensile strength, ⅜” diam. x 3 ⅛” length with ¾” head diameter.

Clip Material: DriftTrak – Headed Stud can be used with DTSLB-HD and DTLB-HD clips: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 97mil minimum thickness (12 gauge, 0.1017” design thickness) with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating.

Catalogs

|

|

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

US Patents #7,503,150 & Patent Pending

DriftTrak® Bypass Downloads

DriftTrak® Bypass Applications

The unique design of MasterClip allows it to be installed either as a vertical deflection connection or a rigid connection. Attachment to the primary structure may be made with a PAF, screw/bolt anchors, or weld and is dependent upon the base material (steel or concrete) and the design configuration.

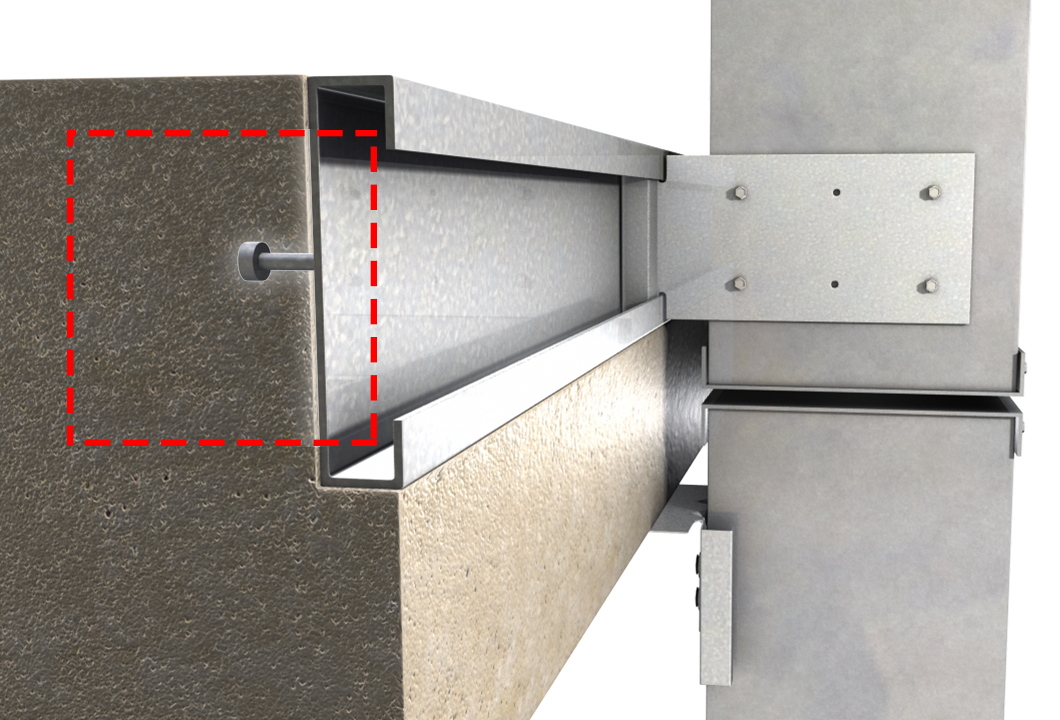

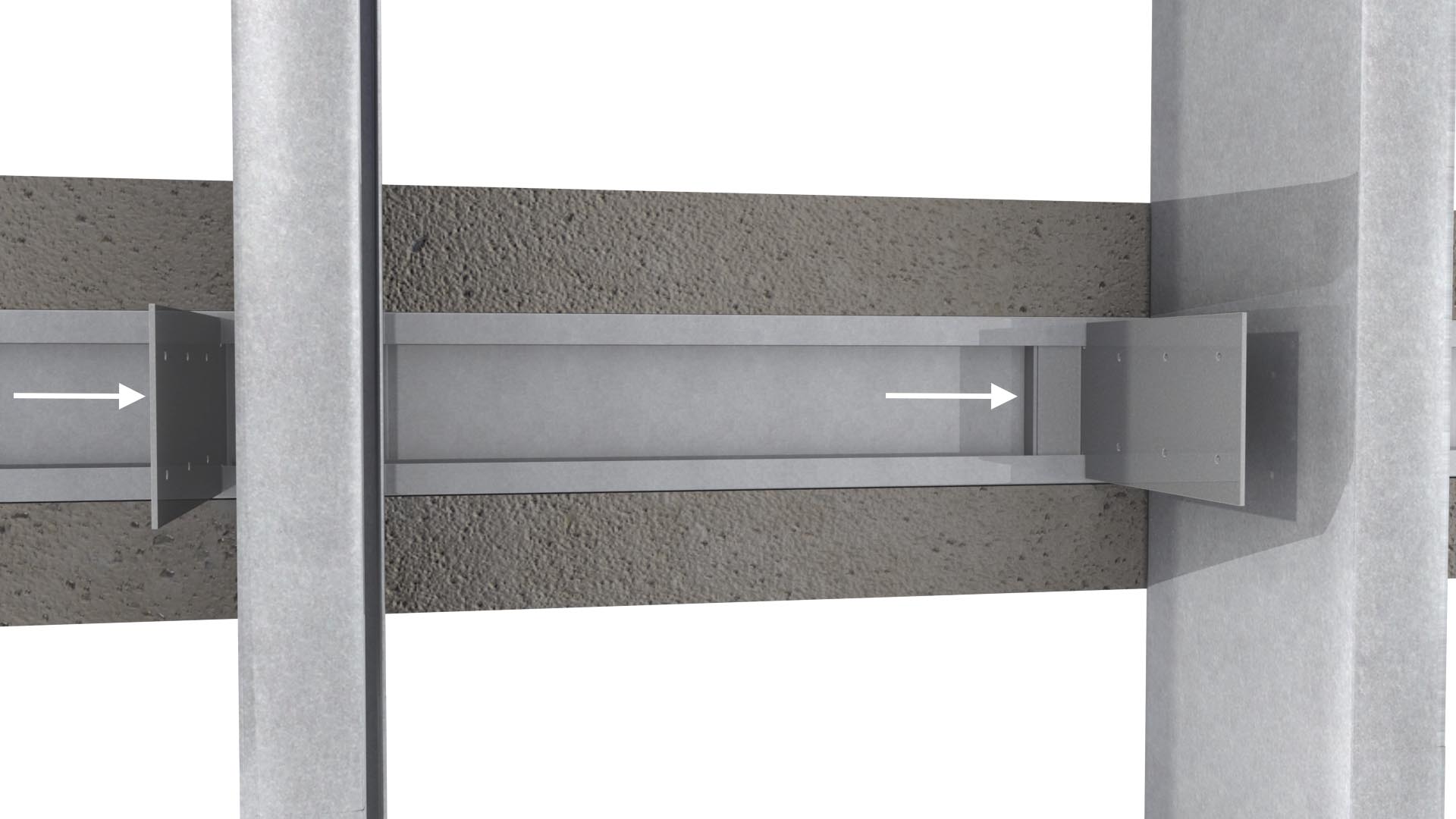

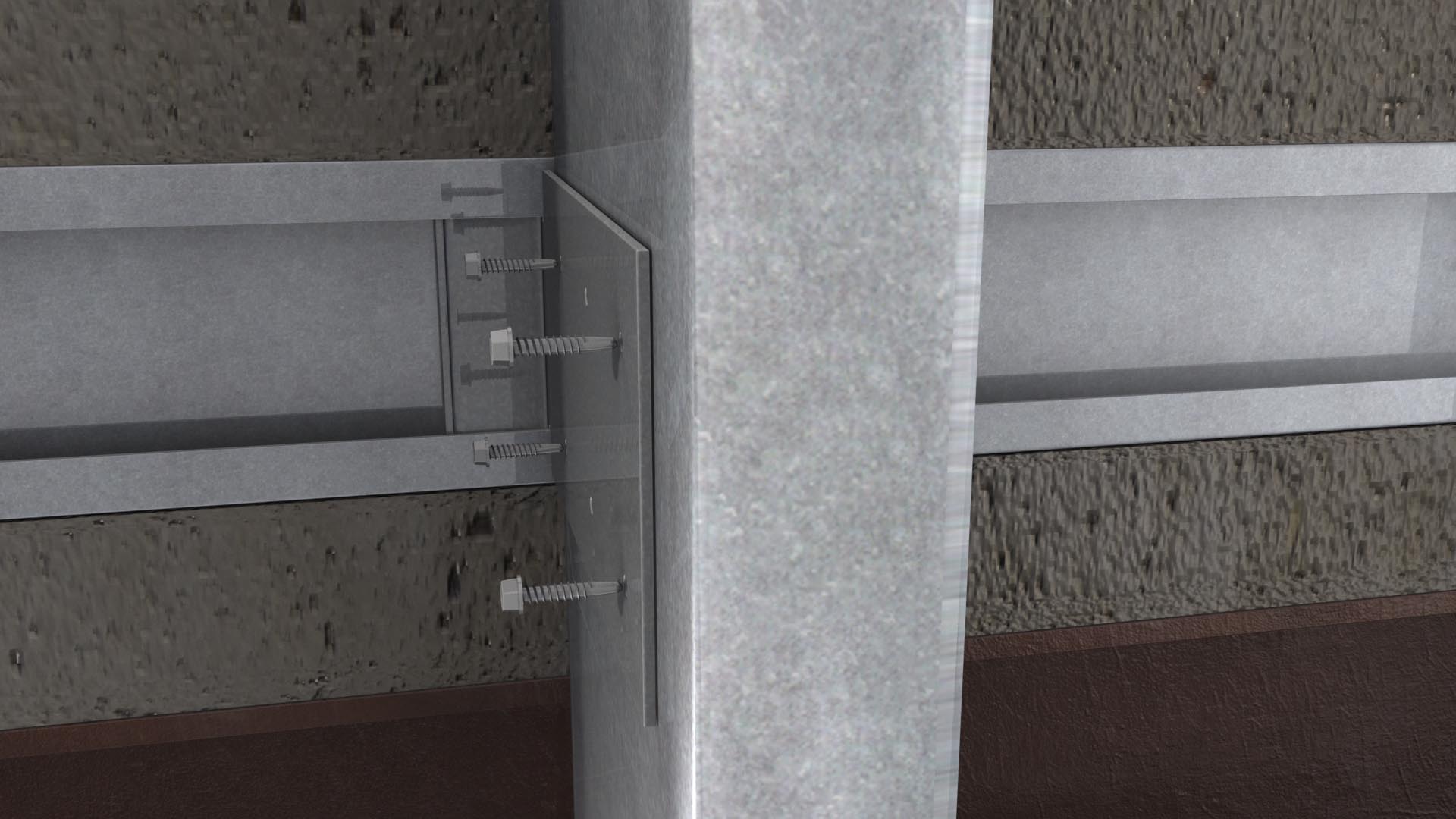

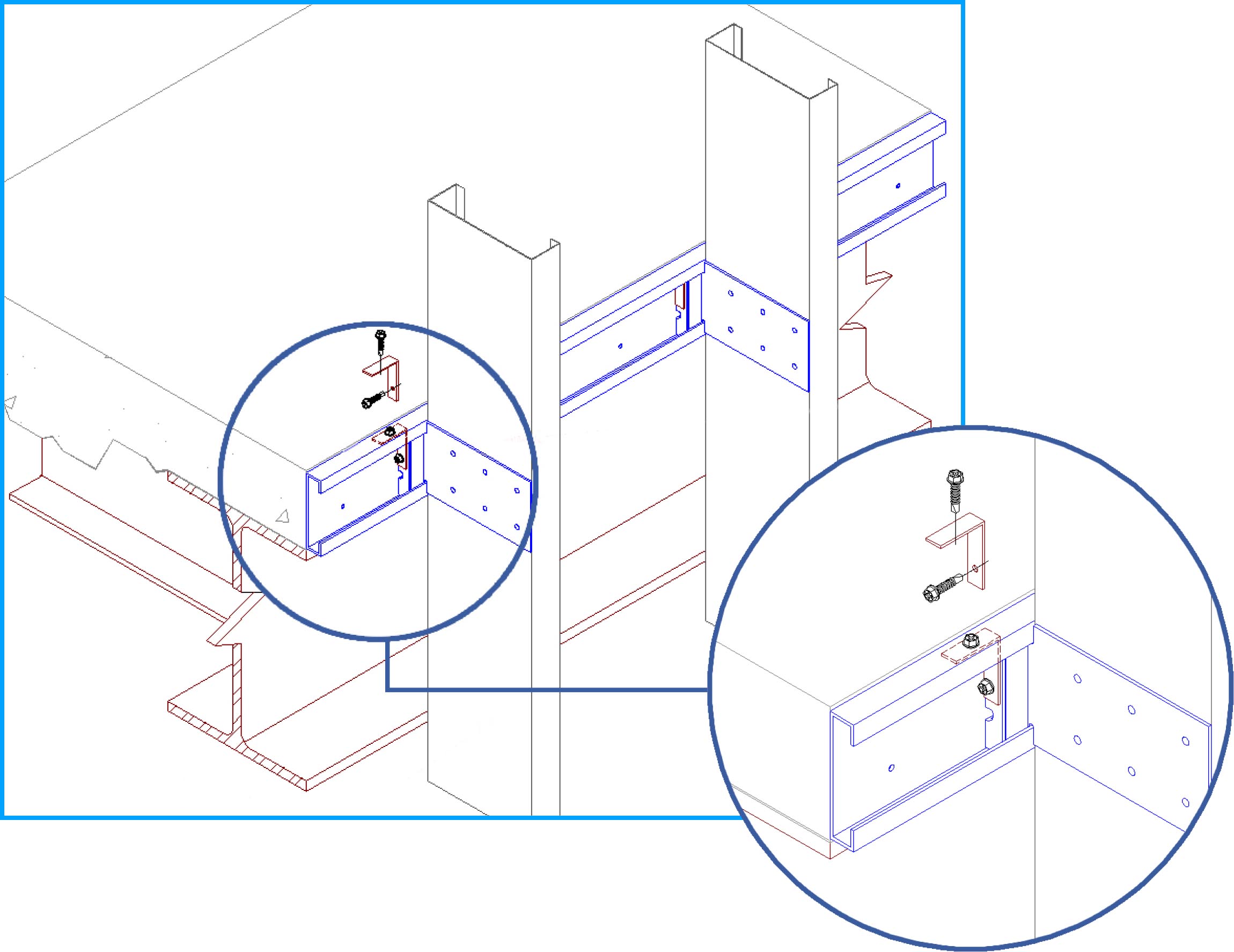

Headed Stud Embedded into Slab for Curtain Wall Slab Bypass as a Drift Connection with No Vertical Deflection

Installation Instructions

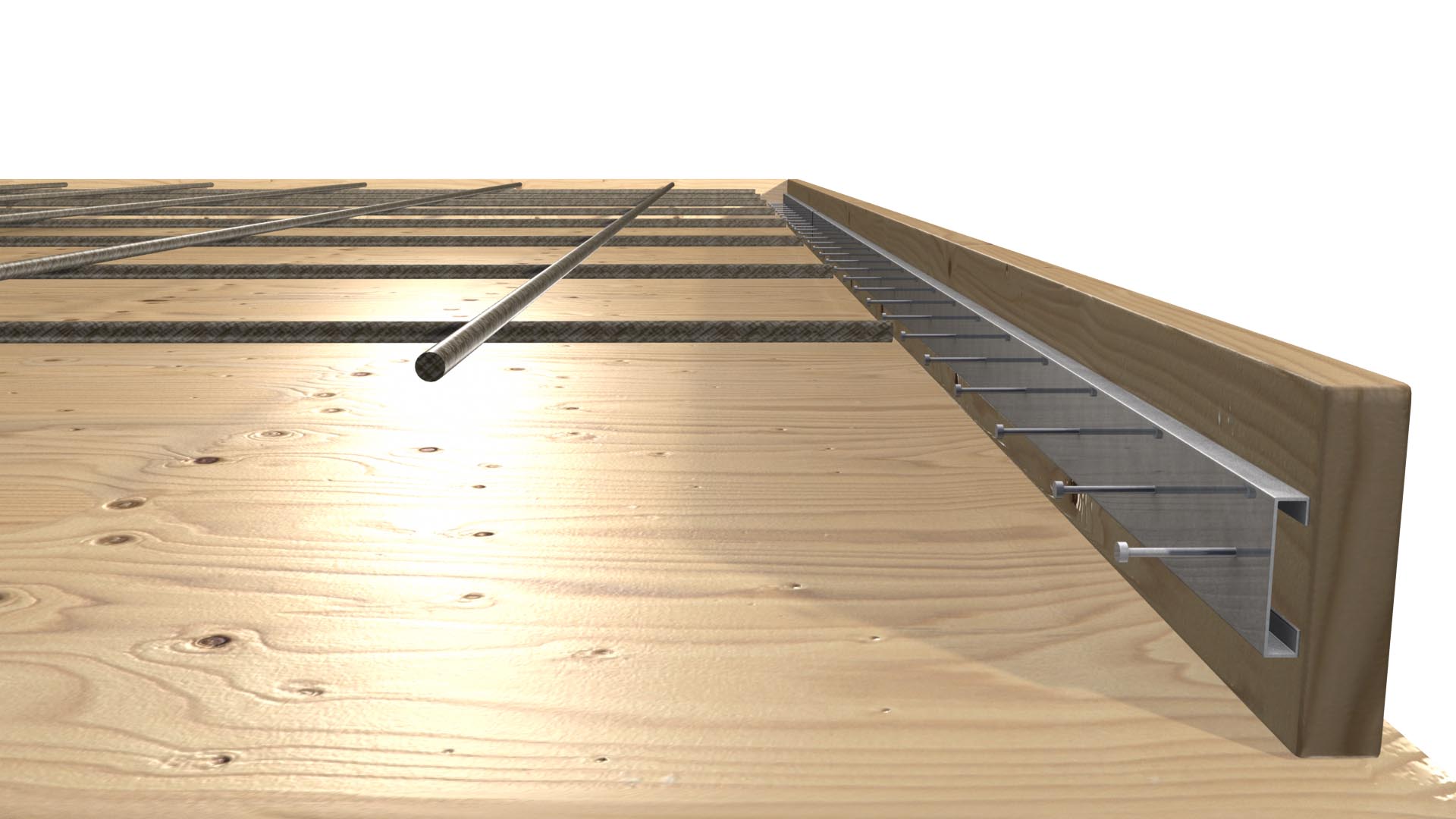

Step 1: Insert DTH inside concrete slab form prior to pouring concrete.

Step 2: Adjust DTH vertically per design details. Block end to prevent concrete seepage.

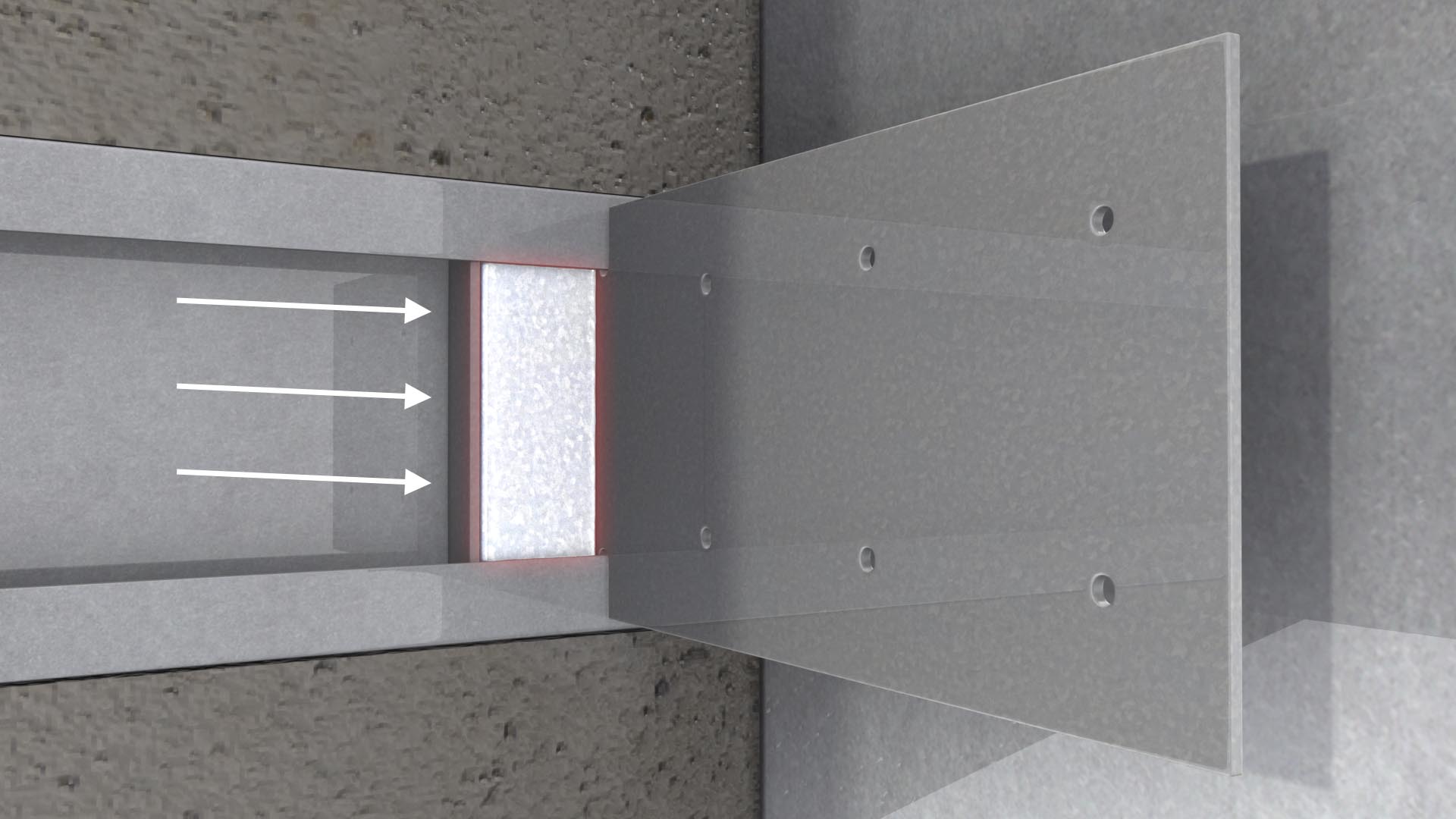

Step 3: After concrete form is removed, twist clips into DTH track.

Step 4: Install stud panel and slide clips into place.

Step 5: Ensure stiffener is in place.

Step 6: Attach stud to clip with specified fasteners through guide holes.

Optional Step: To lock lateral movement, fasten DT-LA (Locking Angle) to DriftTrak components using #12 screws (not included). Locking is recommended at 4 ft. spacing or 3rd stud, max.

DriftTrak® Headed Studs Allowable Loads:

Load Table Notes:

- Clips are manufactured to fi t into the DriftTrak PTS and provide a rigid/slip connection to the stud and allow free lateral movement of the structure.

- Design loads are for attachment of DriftTrak to stud and DriftTrak itself. Load tables reflect horizontal loads (F2) and vertical loads (F3).

- Loads listed reflect force in a single direction. When multiple loads react on the connection, it is the responsibility of the designer to check the interaction of forces.

- Allowable load tables incorporate eccentric loading of fasteners.

- Torsional effects are considered on screw group for F3 allowable loads. It is assumed that all of the torsional moment is taken by the connection to the stud.

- Allowable loads have not been increased for wind, seismic, or other factors.

- Maximum tension on a single anchor should not exceed 1,600 lbs. ASD. In tension and shear, the strength of the anchor itself should be considered. The weld does not need to be considered in tension or shear as the load table and 1,600 lb. ASD tension maximum are inclusive of the strength of the welds.

- Designers must check headed stud tension and shear anchorage capacity in concrete per ACI 318 based on actual headed stud edge distance and concrete compressive strength. For more information, call TSN Technical Support.

- One row of bridging is recommended at a maximum distance of 18” from DriftTrak if no other stud lateral restraint is present.

- Offset is measured from the open face of the track (slab edge) to the inside face of the stud.

Load Direction

F2 & F3 Load Directions

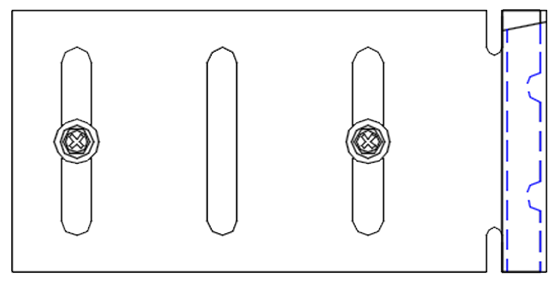

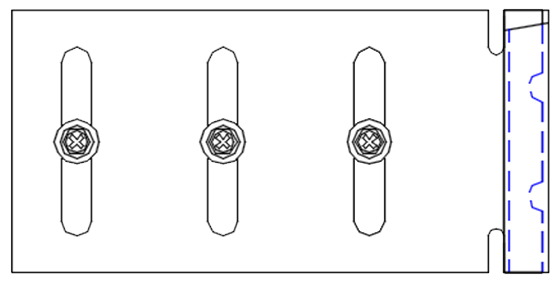

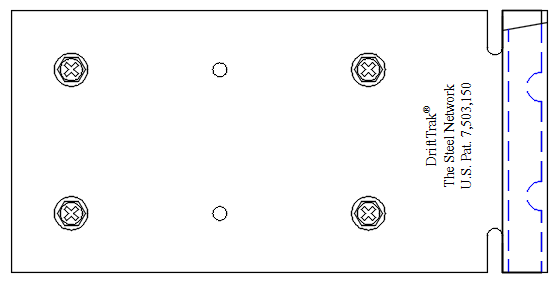

DTSLB-HD 2-Screw Pattern

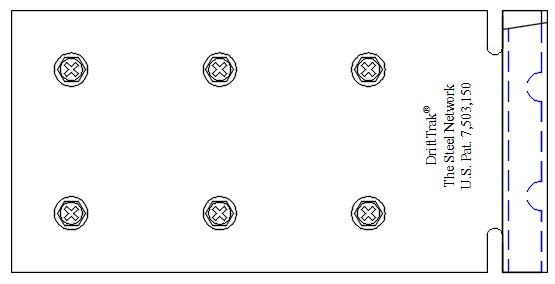

DTSLB-HD 3-Screw Pattern

DTLB-HD 4-Screw Pattern

DTLB-HD 6-Screw Pattern

Follow us on Social Media