Building Information Modeling (BIM), rapidly revolutionizing the construction industry. Overall, engineering and design technology has advanced considerably in the last 30 years within the construction industry. Part of that advancement has led to more and more of the construction process utilizing BIM to save time, reduce complications on the job site, and increase collaboration between designers and trades. The benefits of BIM for the Light Steel Framing (LSF) portion of the project have been previously overlooked in the past because LSF was not seen as a major construction component or considered to have a large effect on the overall project cost. As the usefulness and technology around Light Steel Framing evolves, this opinion is now changing, and the practicality of using BIM to design LSF is more apparent.

This article points out 4 of the biggest ways LSF projects benefit from using BIM.

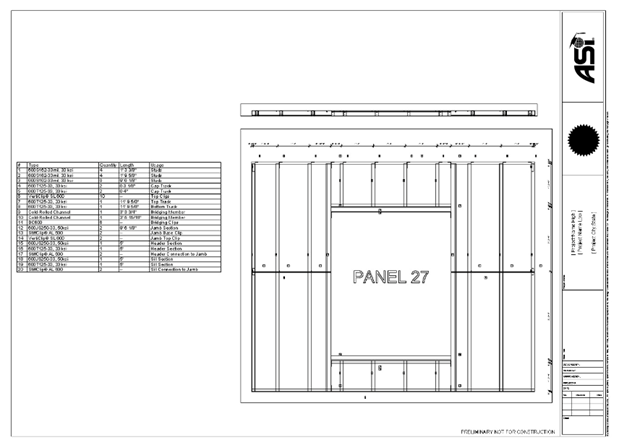

1. Automatically Create Panel & Shop Drawings

Panelization is increasing in popularity as a construction technique. The ability to prefab wall panels in the shop in a controlled manufacturing environment and then plug the panels into place on the jobsite, is a major advantage to a lot of contractors. However, one thing standing in the way of panelization is the cost of creating panel drawings and estimating materials needed for each panel. Shop drawings can be pricey enough, but when panel drawings are added to the mix, the price tag can often be 10’s of thousands of dollars outside of original budget projections.

When a project is modeled in BIM, there is no cumbersome process to produce extra drawings. Provided the appropriate BIM software is being utilized, you will not have to go through an extra step to create shop drawing and panel drawings. Once the framing has been fully modeled, the shop drawings, panel drawings, and materials lists can be automatically created with the click of a button.

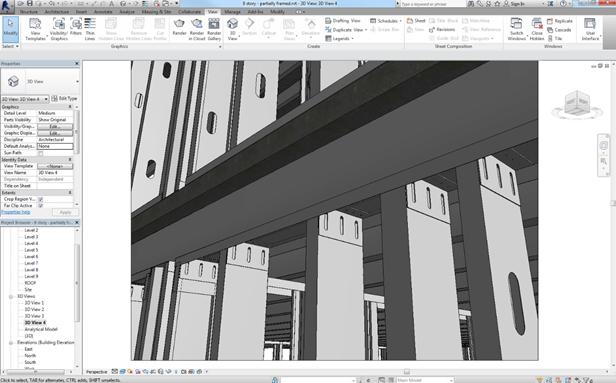

2. BIM Models Spot Problems Early in the Process

Resolve potential conflicts between light steel framing and other building components early in the design phase, before construction has begun. This saves countless hours that would be wasted if this problem had to be addressed in the field after construction materials have been ordered or the building is near completion.

One advantage of this level of detail is the ability to look at the comprehensive 3-D model and see how the entire steel framing system works together, even down to the connector level. This avoids situations where the contractor might find himself having a hard time making something fit and he is forced to improvise on the spot or go through the lengthy submittal process with the engineer to get the modification approved. In some cases, this kind of unexpected problem can cause construction to come to a halt until a solution is found. With a BIM model, this problem would have been spotted early on, and dealt with months before the construction phase.

You can view the model on a mobile device during walk throughs of the construction site or even on your favorite virtual reality (VR) headset. Discrepancies between the plans and the actual framing can be spotted and dealt with quickly.

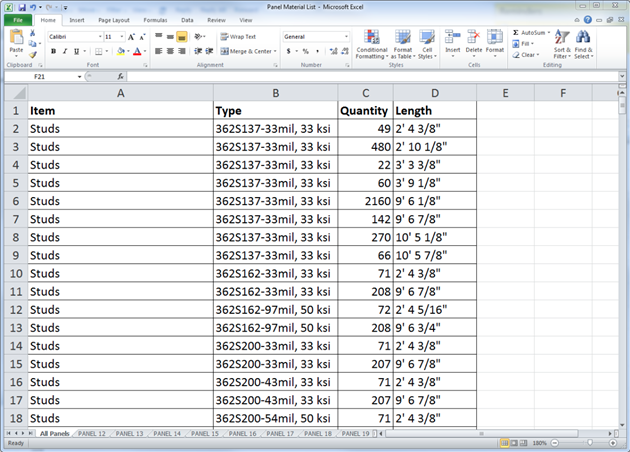

3. Material Ordering

A big advantage of BIM is the time savings enjoyed during the material estimation and ordering phase of the project. The traditional process means spending days pouring over plans to determine quantities and measurements. With BIM, once your project is modeled, you are able to instantly see exact quantities and lengths for all light steel framing components and export them to an excel sheet for quoting and ordering. This process makes your material estimates more accurate and reduces surprises down the road.

Material waste is minimized because the exact lengths for all the framing members can be sent directly to the manufacturer. No more getting trucks full of 12ft steel studs and then setting up a station to cut them to length on site. This method results in wasted material and labor and takes up precious space on the job site. If you are utilizing BIM correctly and using the right manufacturer, materials will show up on the job site cut to length, bundled together by panel, and labeled so that materials can be easily put in place by the crew. This allows the contractor to focus on the other aspects of construction.

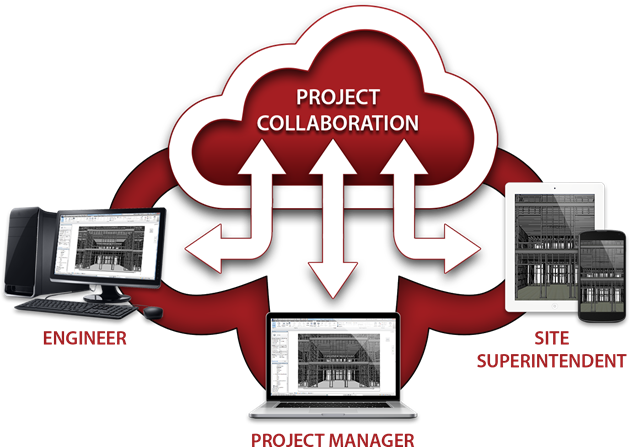

4. Make Coordinating with Trades Easy

BIM gives teams the ability to review and comment on a full 3-D model from anywhere using your computer, tablet, or mobile phone. This can really be helpful for coordinating projects with other trades. The electrician, plumber, drywaller, and framer can all look at the same model and make notes for eachother. This level of coordination is only possible inside of a BIM environment. No more sorting through months of emails to find notes on specific component details. When changes are solidified, project plans are updated instantly for all parties.

Case Studies

1. Labor Savings

F.L. Crane utilized a BIM model when they built Bluebonnet Studios, a 107-unit apartment building that required 750 panels to enclose. The BIM team was able to meet with other trades and use the model they created to head off building scheduling conflicts. According to the BIM Manager, it produced substantial labor savings.

2. Time Savings

When South Valley Drywall built a 73 bedroom Ronald McDonald House they were able to model the entire project and eliminate all RFIs on the project. According to South Valley, Panel prefabrication cut two months off the construction schedule.

Conclusion

The benefits of BIM for Light Steel Framing can be summed up through increased collaboration and automation. By using one BIM files, everyone on the team stays on the same page, and because all of the information is in one place, and is extremely detailed, things like shop drawings and material orders are naturally much less complicated.

If you would like to start a 30 day trial of our Cold Formed Steel BIM software fill out the form below: