iSEAL EP

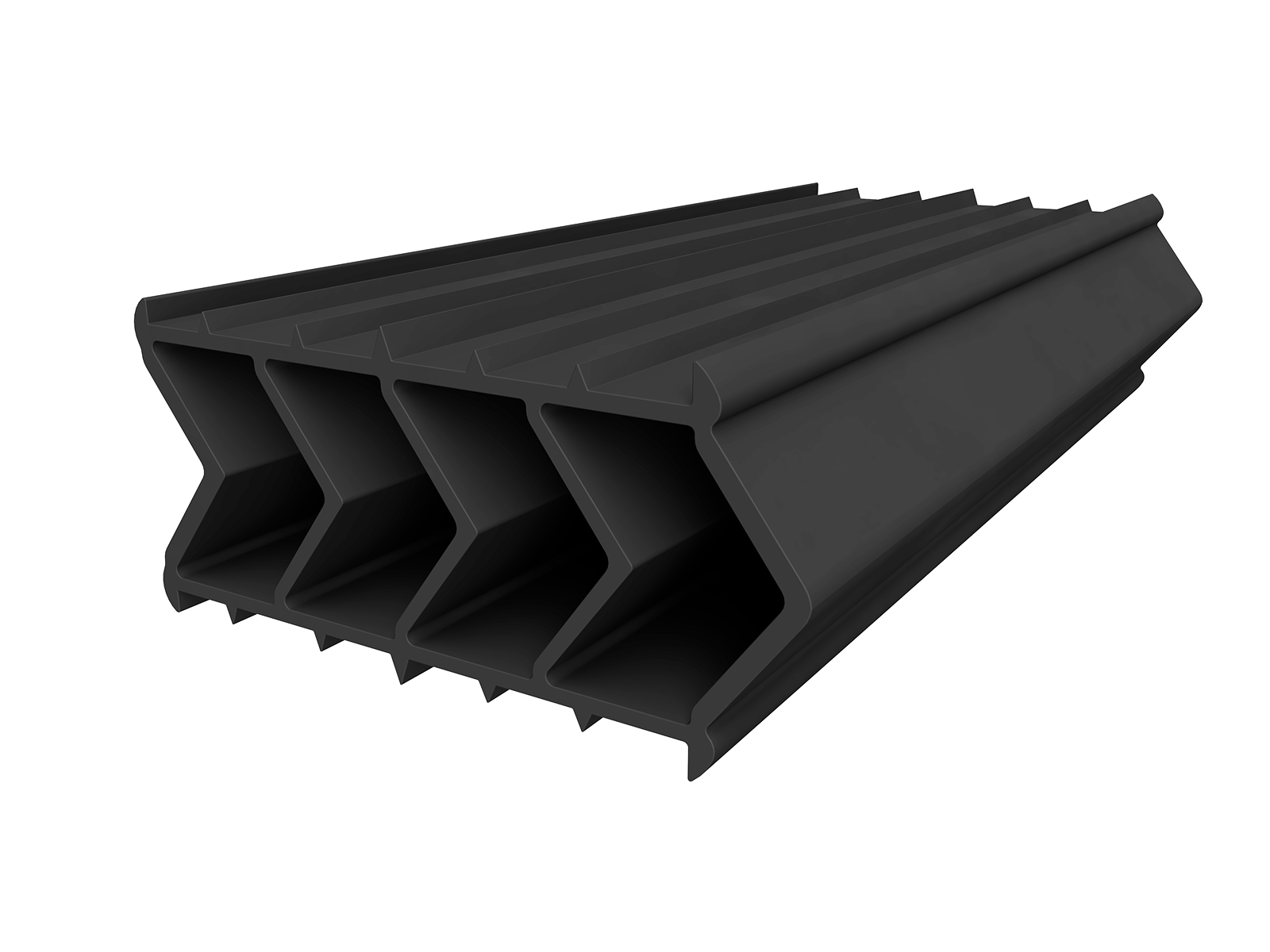

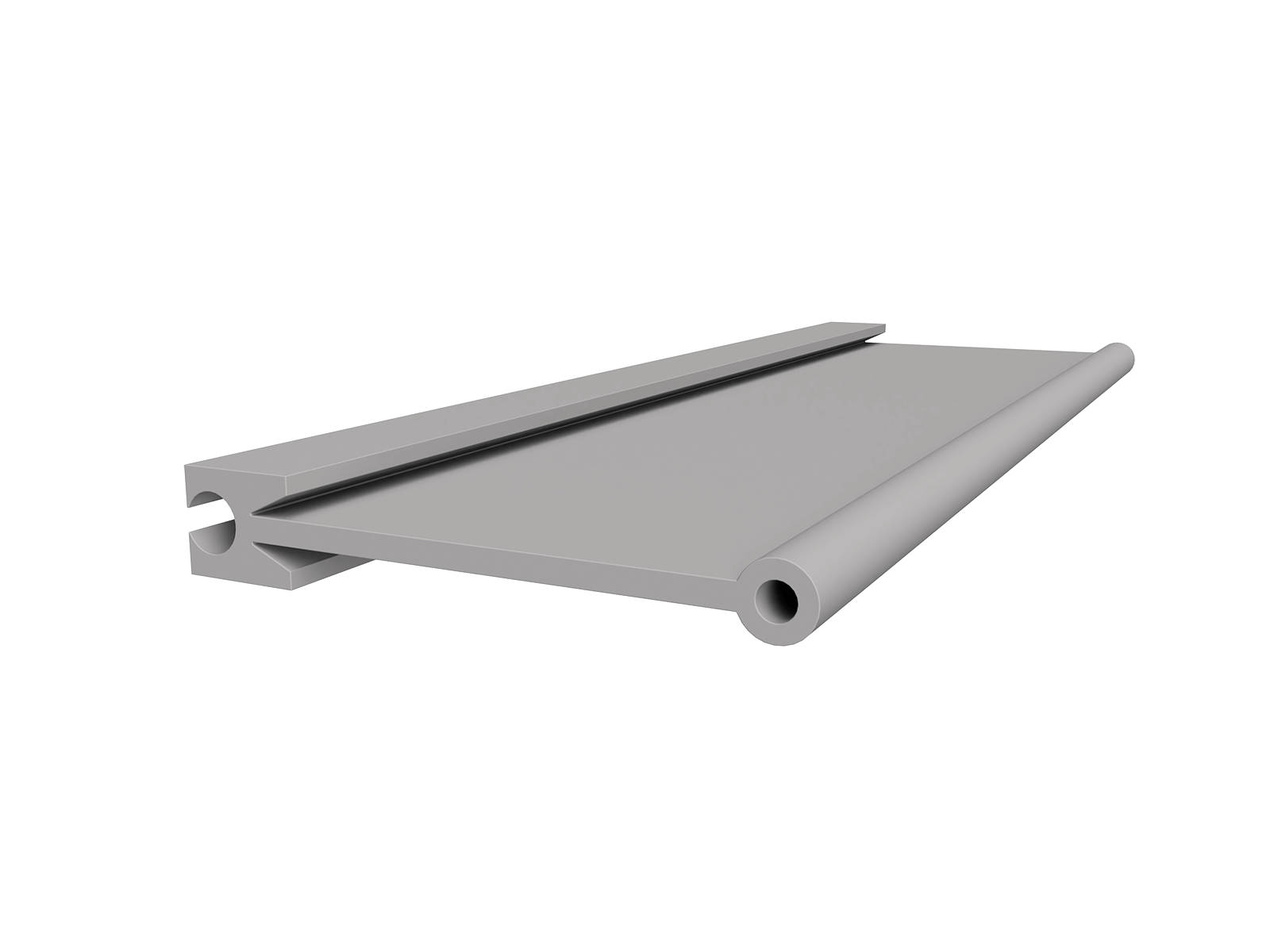

PeerEngine’s iSEAL EP (Exterior Panel) is a compressed fit extruded silicone gasket system developed specifically for panel technology. iSEAL EP is for above grade exterior wall panel conditions, it provides thermal protection, air & water infiltration protection, and is not susceptible to UV damage.

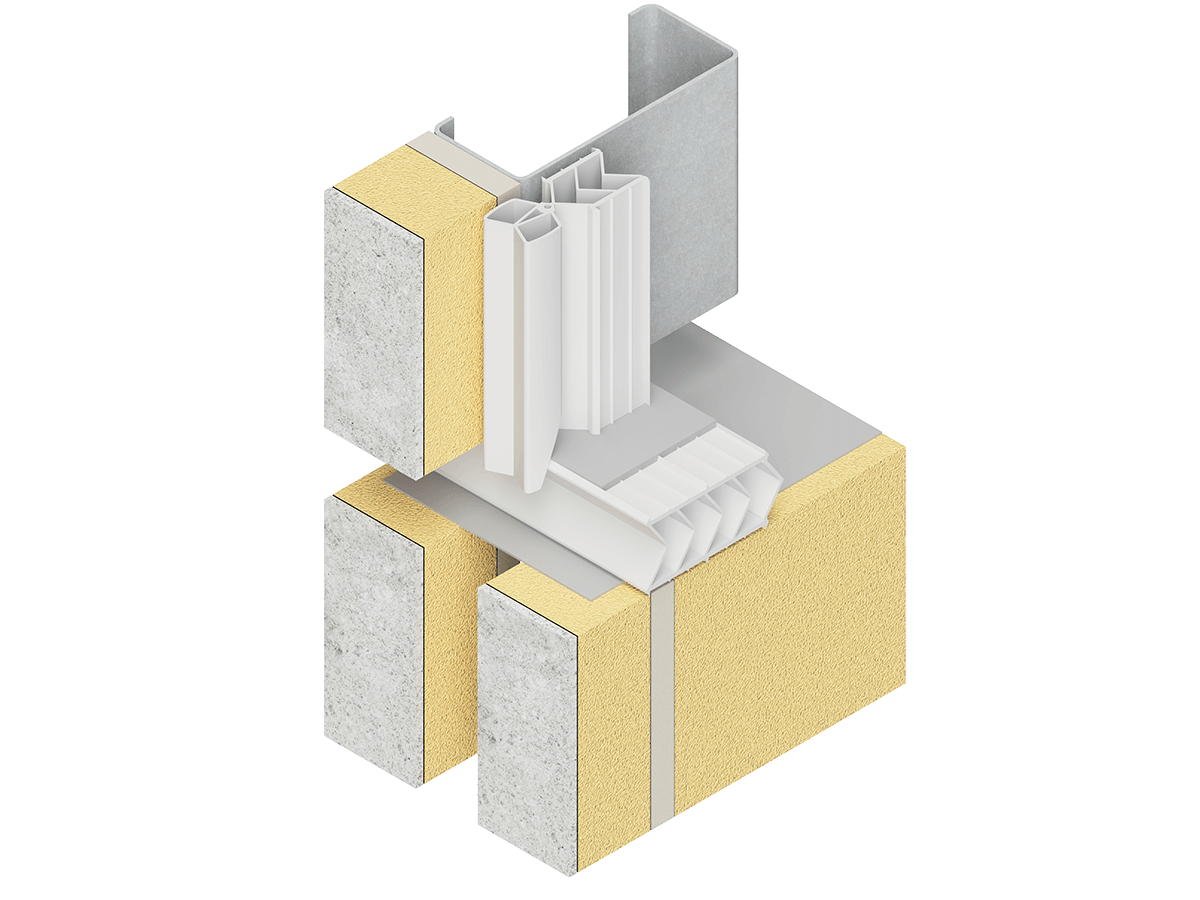

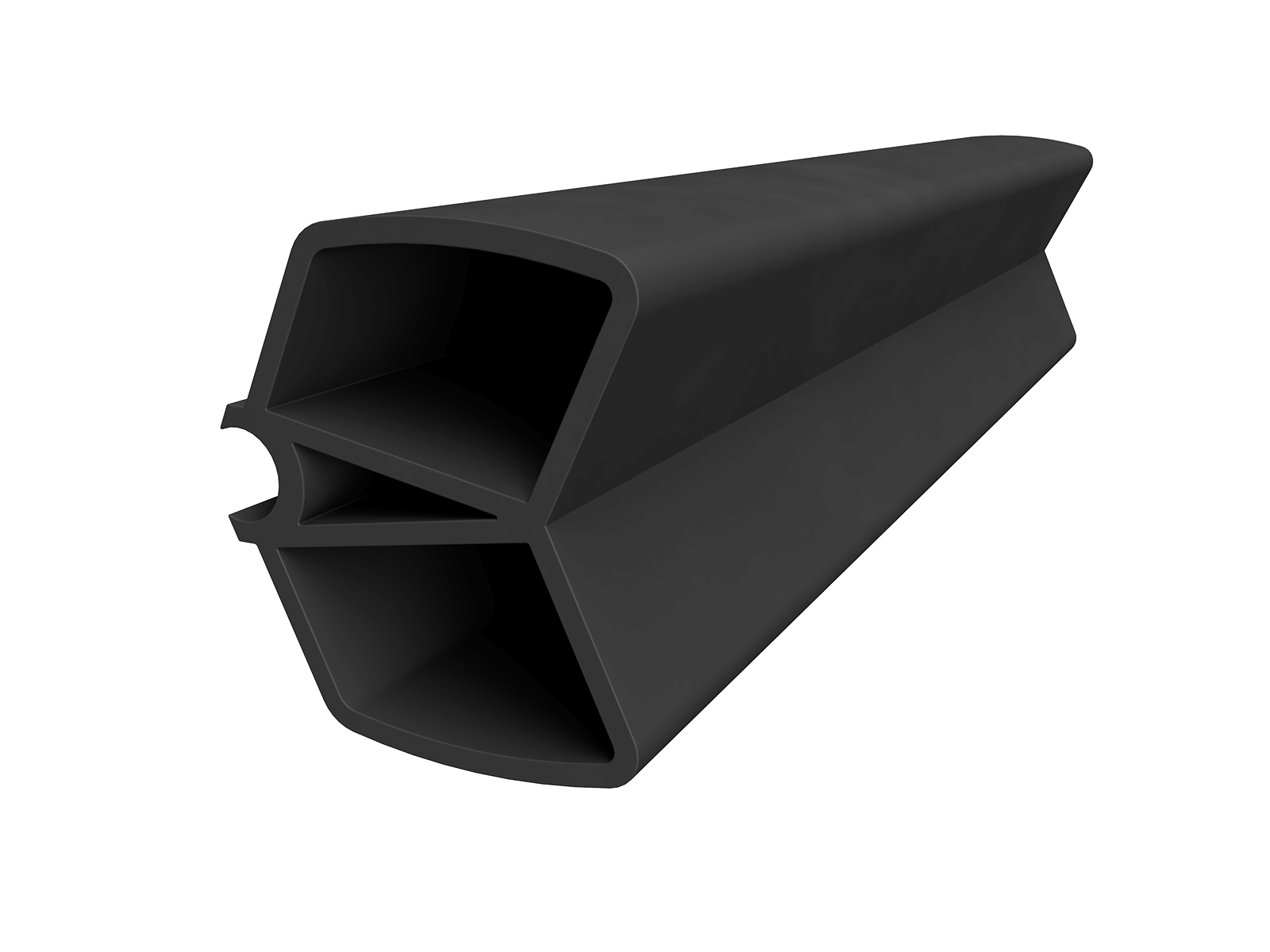

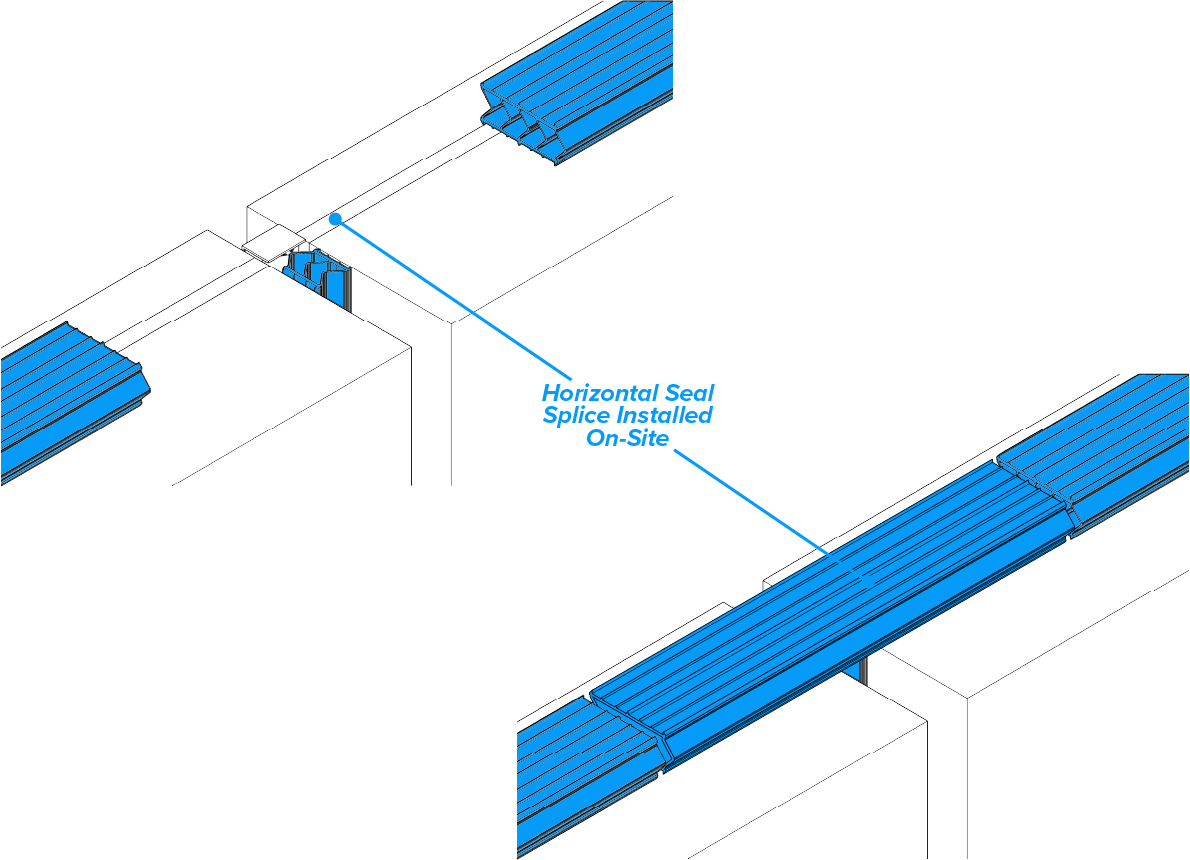

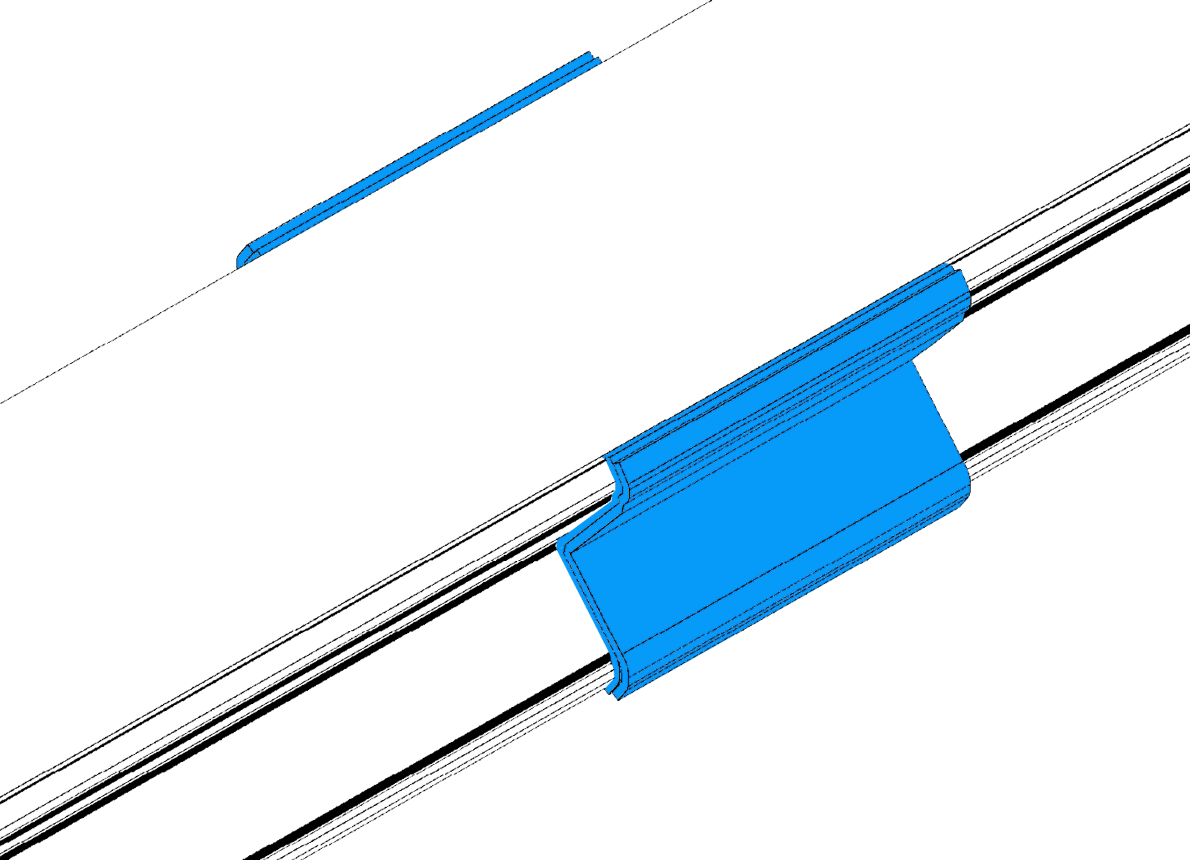

The system consists of extruded silicone gaskets that are adhered to the substrate/panels with silicone sealant. A proprietary iSEAL EP Exoskeletal 4-way splice is used at all four-way vertical-to-horizontal splices to ensure continuity of performance at splices.

*The Steel Network, Inc. (TSN) is the exclusive distributor for iSeal EP, by PeerEngine, LLC. For more warranty information, see PeerEngine’s iSeal EP Limited Warranty.

Features

| Structural | ASTM E330: Pass at 60 PSF |

| Air Leakage | ASTM E283: <0.04 CFM @ 6.24 PSF |

| Water (Dynamic) | AAMA 501.1: Pass at 15 PSF |

| Water (Static) | ASTM E331: Pass at 15 PSF |

| Interstory Drift | AAMA 501.4: No damage at 1% of story height, No damage at +/-¾” vertical displacement |

Order Info

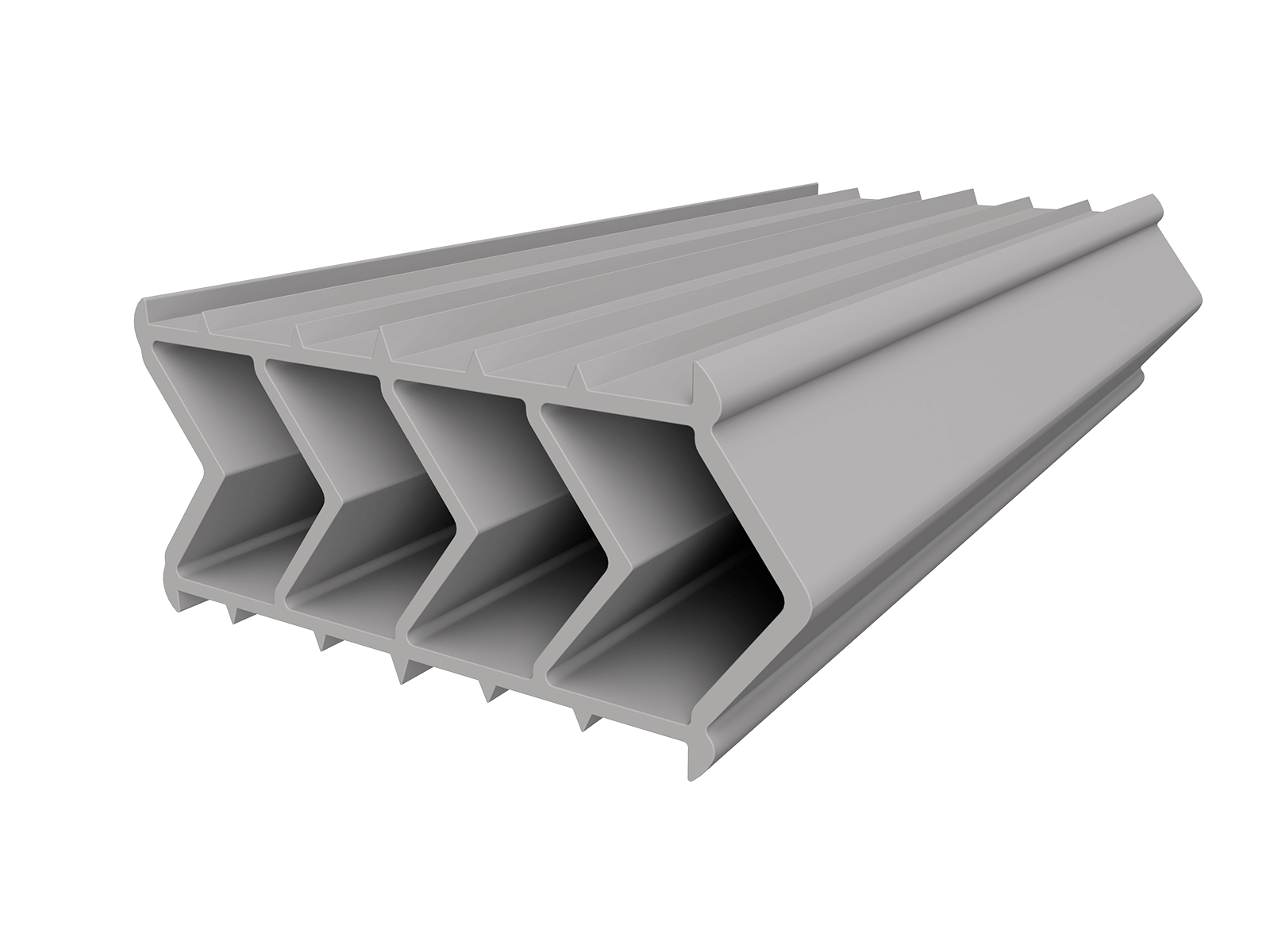

| Product | Packaging | |

|

IHB; 70 DUROMETER BLACK SILICONE | 500 FT/REEL (327 Lbs.) |

|

IVB; 70 DUROMETER BLACK SILICONE | 500 FT/REEL (171 Lbs.) |

|

IVW; 70 DUROMETER BLACK SILICONE | 500 FT/REEL (119 Lbs.) |

|

IHS; 70 DUROMETER BLACK SILICONE | 100 FT/BOX (167 Lbs.) |

|

IVE; 85 DUROMETER BLACK SILICONE | 450 FT/BOX (86 Lbs.) |

|

IHB; 70 DUROMETER GRAY SILICONE | 500 FT/REEL (327 Lbs.) |

|

IVB; 70 DUROMETER GRAY SILICONE | 500 FT/REEL (171 Lbs.) |

|

IVW; 70 DUROMETER GRAY SILICONE | 500 FT/REEL (119 Lbs.) |

|

IHS; 70 DUROMETER GRAY SILICONE | 100 FT/BOX (167 Lbs.) |

|

IVE; 85 DUROMETER GRAY SILICONE | 450 FT/BOX (86 Lbs.) |

Material Composition

Refer to the tables below

- Technical Data

- Gasket Seal - Physical Properties

- Silicon Building Sealant - Physical Properties

- Warranty

| Structural | ASTM E330: Pass at 60 PSF |

| Air Leakage | ASTM E283: <0.04 CFM @ 6.24 PSF |

| Water (Dynamic) | AAMA 501.1: Pass at 15 PSF |

| Water (Static) | ASTM E331: Pass at 15 PSF |

| Interstory Drift | AAMA 501.4: No damage at 1% of story height, No damage at +/-¾” vertical displacement |

|

70 Durometer Silicone This is commercial grade profile extrusion compound. General Purpose: ASTM C1115, Type C

|

|||

| Properties | Specifications | Typical Value | Test Method |

| Hardness, Type A, Pts. | 70 ± 5 | 74 | ASTM D2240 |

| Tensile, min, MPA (psi) | 5.0 (725) | 8.4 (1224) | ASTM D412 |

| Elongation, Min, % | 125 | 306% | ASTM D412 |

| Specific Gravity | Report | 1.37 | ASTM D792 |

| Tear Resistance, Die B, | |||

| Min, kN/m (lbf/n) | 9 (51) | 24.5 (140) | ASTM D624 |

| Compression Set, 22 hrs @100° C | |||

| Method B, Max, % | 15 | 7.5% | ASTM D395 |

| Heat Resistance, 70 hrs @150° C | ASTM D573 | ||

| Change in Hardness, max, pts | ±5 | +2 | |

| Change in Tensile, max, % | ±15 | +1.0 | |

| Change in Elong., max, % | ±30 | -26.0 | |

| Low Temperature Brittleness, 3 minutes @ -40° C | ASTM D2137 | ||

| Method A, No Cracks or Cracking | Passed | ||

| Ozone Resistance, 100 hrs @ 300mPa @ 70° C, 20% elongation | ASTM D1149 | ||

| Method B, Procedure B1, 7x, No Cracks or Cracking | Passed | ||

| Staining of Surface, 48 hrs @70° C, Delstar Acrylic White Enamel in conjunction with Satin Primer DPE-1338 |

ASTM D925 | ||

| Method A, No Contact Stain | Passed | ||

| Staining of Surface, 48 hrs w/UVA-340 bulbs per ASTM G-154, Delstar Acrylic White Enamel in conjunction with Satin Primer DPE-1338 |

ASTM D925 | ||

| Method B, No Contact Stain | |||

| Dow Corning 795 Silicone Building Sealant | |||

| Test | Property | Unit | Result |

| As Supplied | |||

| ASTM C 679 | Tack-Free Time, 50% RH | Hours | 3 |

| Curing Time at 25°C (70°F) and 50% RH | Days | 7-14 | |

| ASTM C 639 | Flow, Sag or Slump | Inches (mm) | 0.1 (2.54) |

| Working Time | Minutes | 20-30 | |

| VOC Content1 | g/L | 28 | |

| As Cured-After 21 days at 25° (77°F) and 50% RH | |||

| ASTM D2240 | Durometer Hardness, Shore A | Points | 35 |

| ASTM C794 | Peel Strength | Lb/in (kg/cm) | 32 (5.7) |

| ASTM C 1135 | Tension Adhesion Strength | ||

| At 25% extension | Psi (MPa) | 45 (0.310) | |

| At 50% extension | Psi (MPa) | 60 (0.414) | |

| ASTM C 719 | Joint Movement Capability | Percent | ±50 |

| ASTM C 1248 | Staining (granite, marble, limestone, brick and concrete) | None | |

| As Cured-After 21 days at 25° (77°F) and 50% RH followed by 10,000 hours in a QUV weatherometer, ASTM G 53 | |||

| ASTM C 1135 | Tension Adhesion Strength | ||

| At 25% extension | Psi (MPa) | 35 (0.241) | |

| At 50% extension | Psi (MPa) | 50 (0.345) | |

| 1 Based on South Coast Air Quality Management District of California. Maximum VOC is listed both inclusive and exclusive of ware and exempt compounds. For a VOC data sheet for a specific sealant color, please send your request to product.inquiry@downing.com. | |||

For information on PeerEngine’s iSeal EP, click here

iSEAL EP Downloads

Benefits of the iSEAL Exterior Panel System

PROVEN MATERIALS

The iSEAL EP system uses proven silicone materials. Silicone has been used for over 40 years in conjunction with panel products.

INSTALLATION QUALITY CONTROL

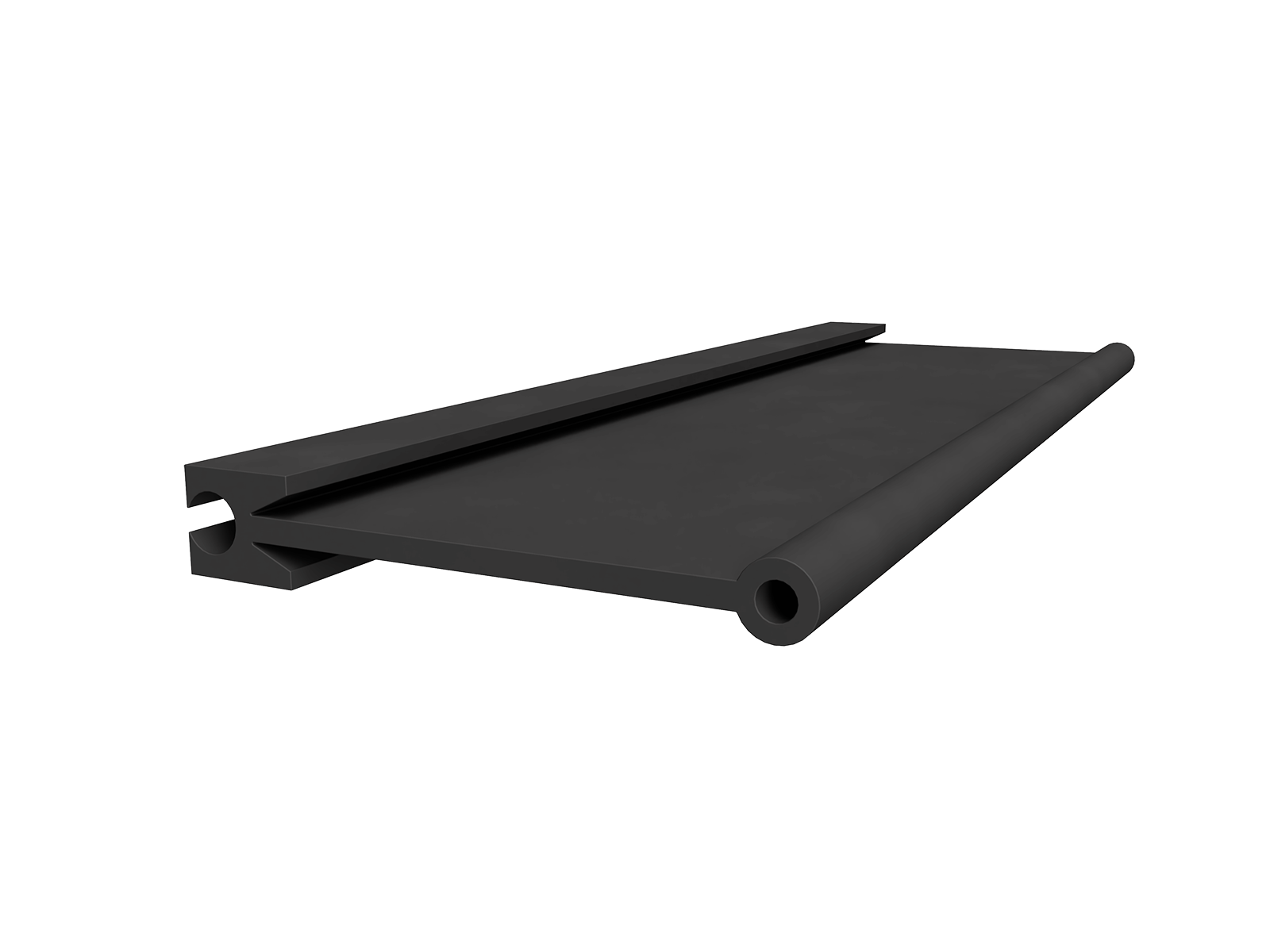

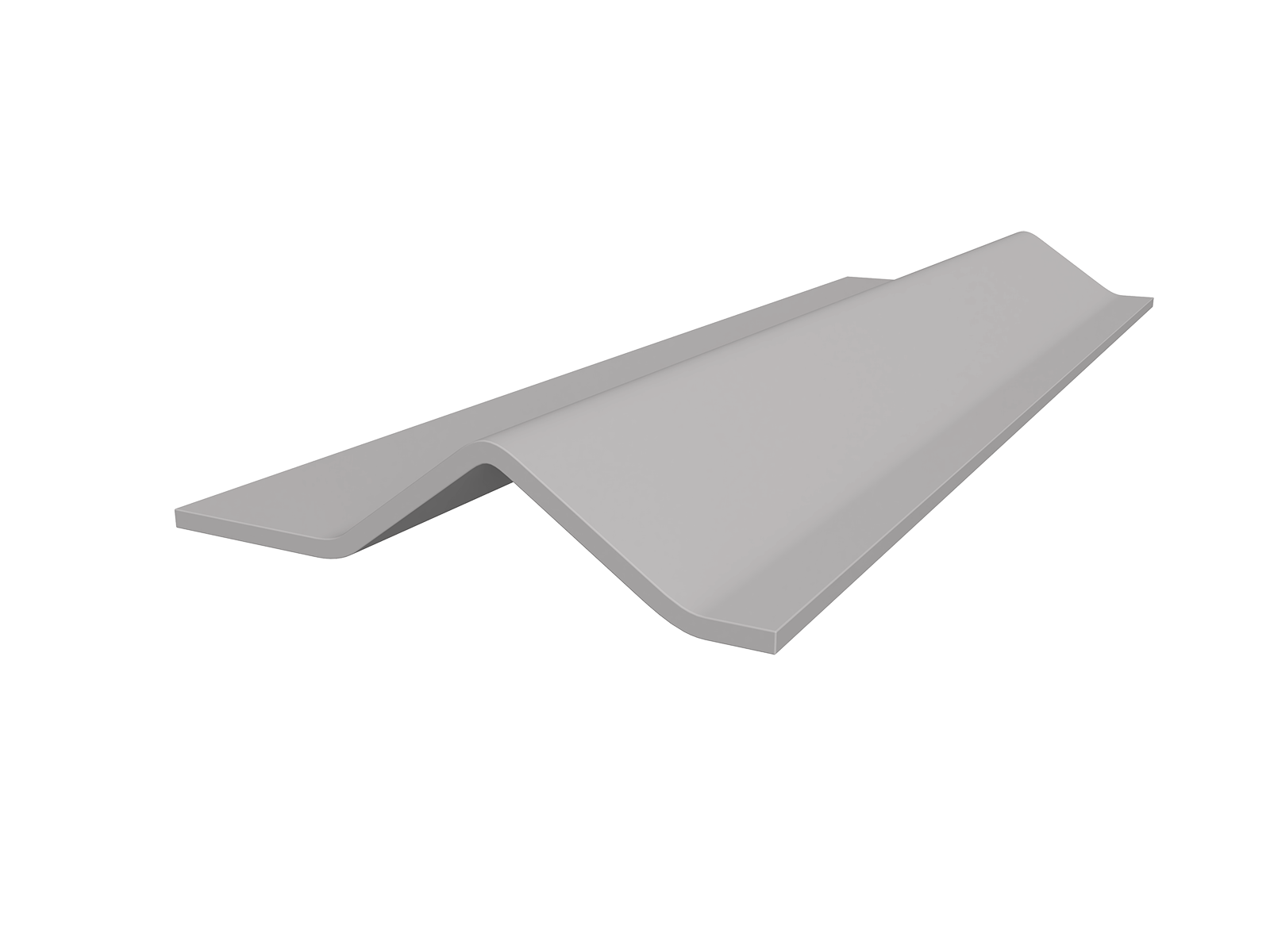

The iSEAL EP extrusion is designed with sealant depth gauging tabs, which allow for easy visual confirmation of correct sealant depth and accurate alignment of panels.

PROVEN PERFORMANCE

The iSEAL EP system, including the exoskeletal 4-way splice has been subjected to rigorous laboratory testing to validate system performance.

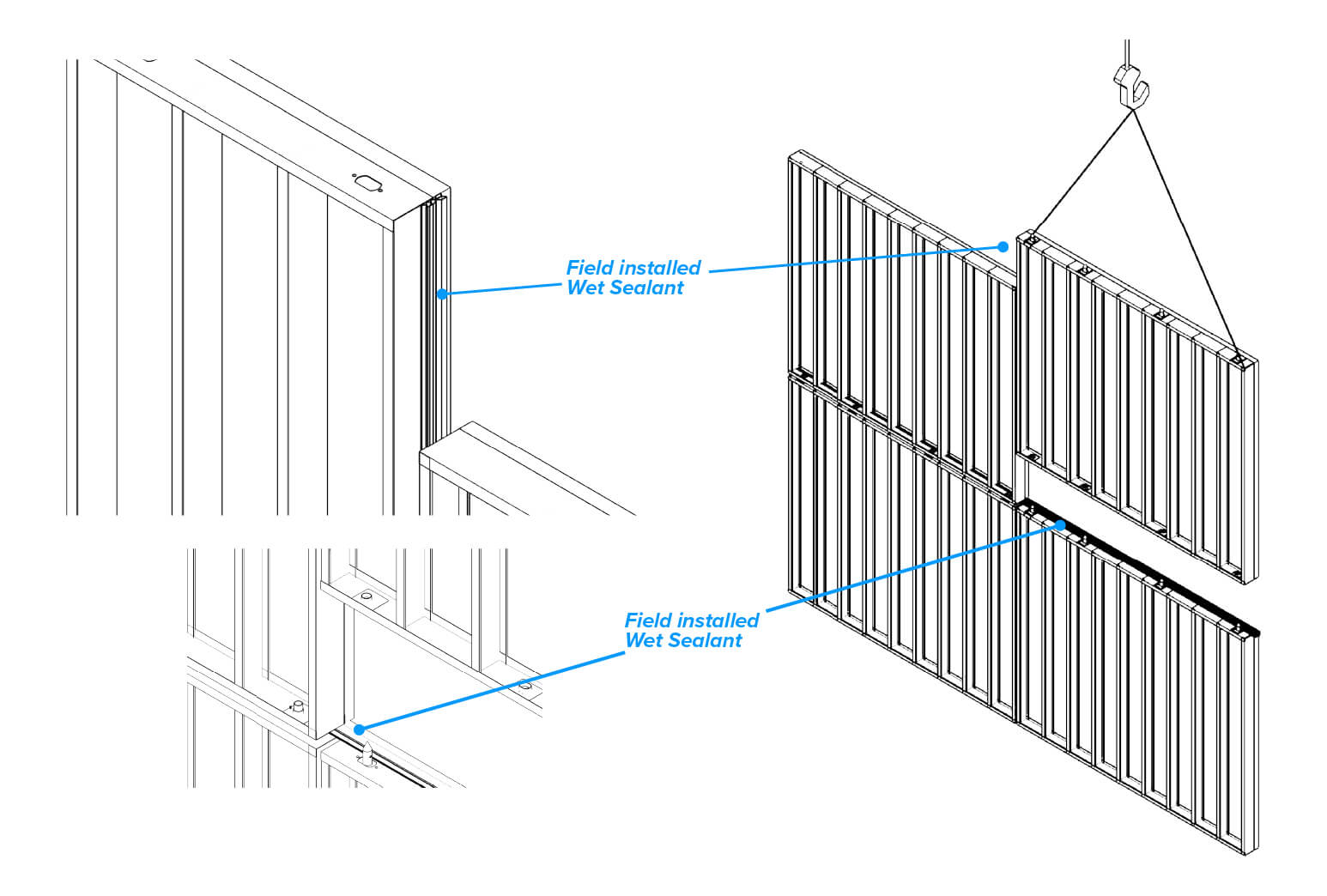

FASTER DRY-IN

With the iSEAL EP system the 4-Way splice joints are installed as the panels are erected, providing completed panel perimeter joints with each installed panel. With traditional sealant/backer rod joints the joints are typically installed after all panels are installed, leaving the building exposed to the elements during construction.

MOVEMENT CAPACITY

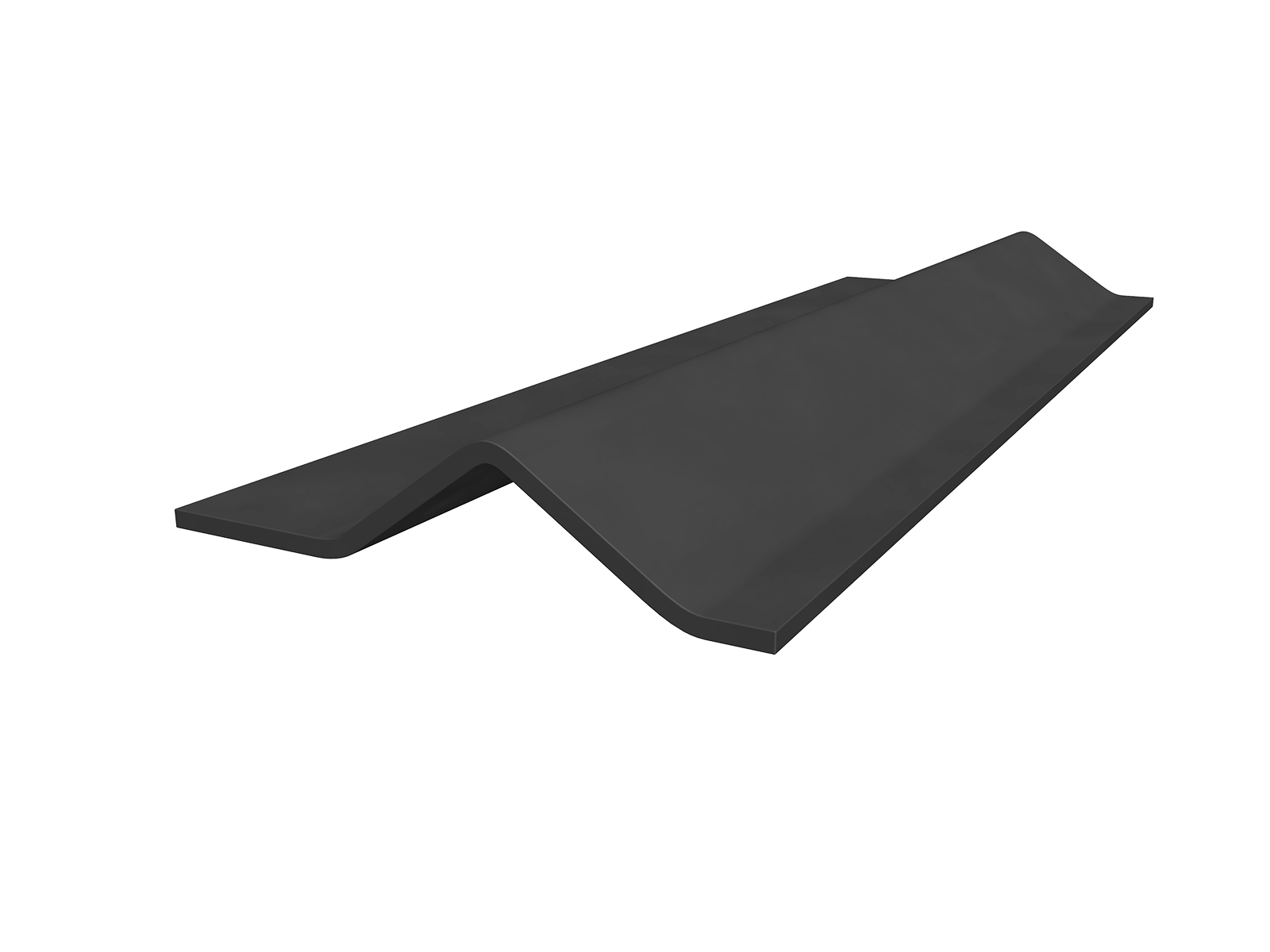

The iSEAL EP gasket is highly flexible and able to easily accommodate building movements while imparting lower loads on the panel joints as compared to a traditional sealant/backer rod joint. This reduces the risk of adhesive joint failure.

FACTORY INSTALLATION QUALITY

Over 90% of the iSEAL EP system is shop installed in a controlled environment with rigorous quality control, eliminating the quality challenges of field installed sealant/backer rod joints.

Example Installation Details

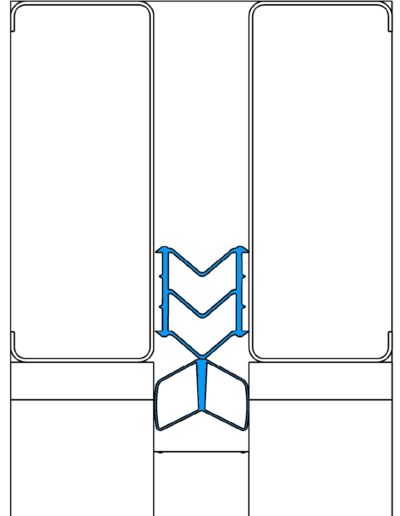

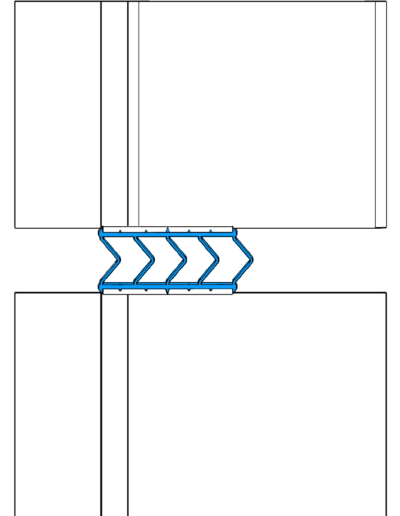

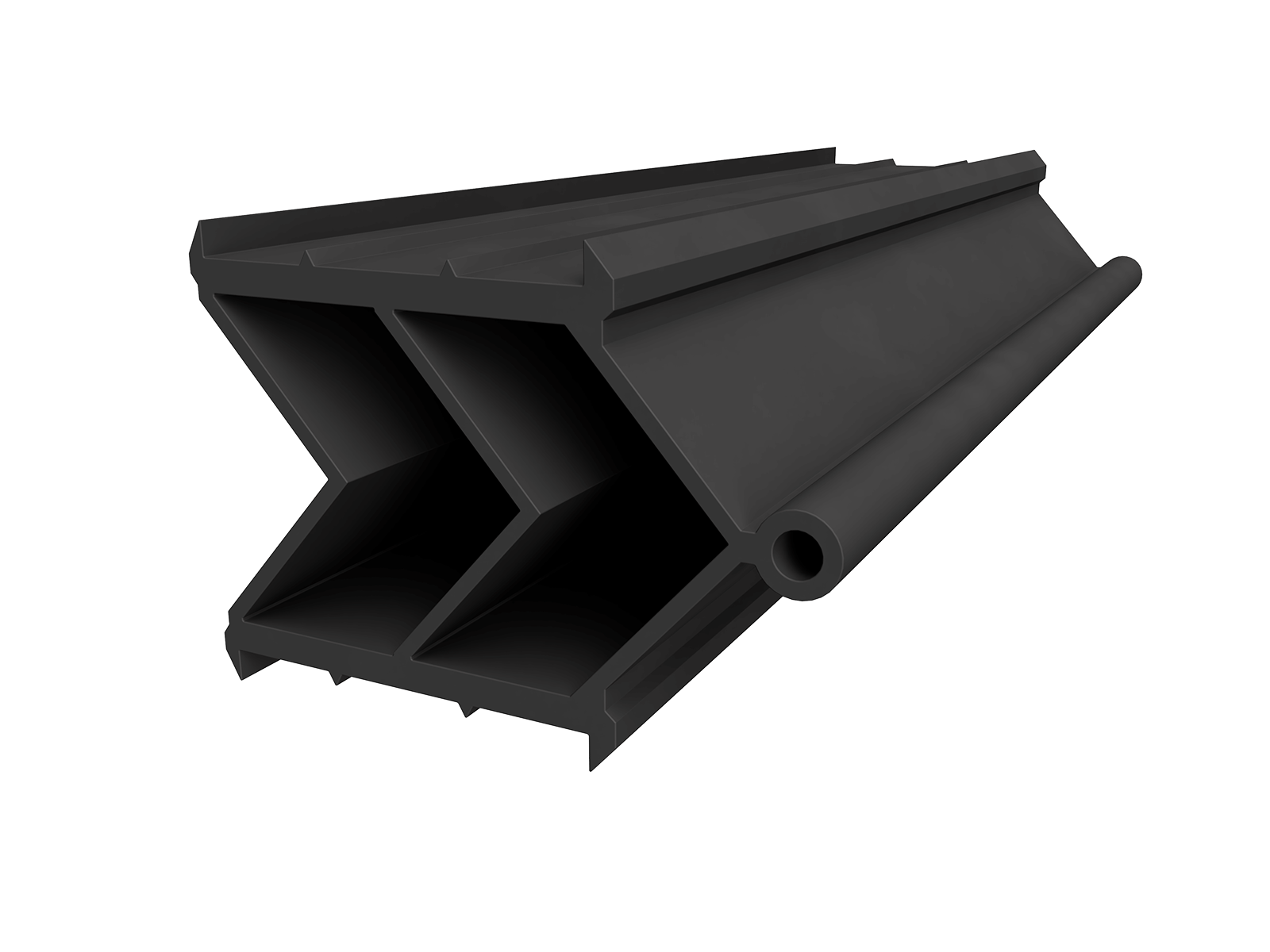

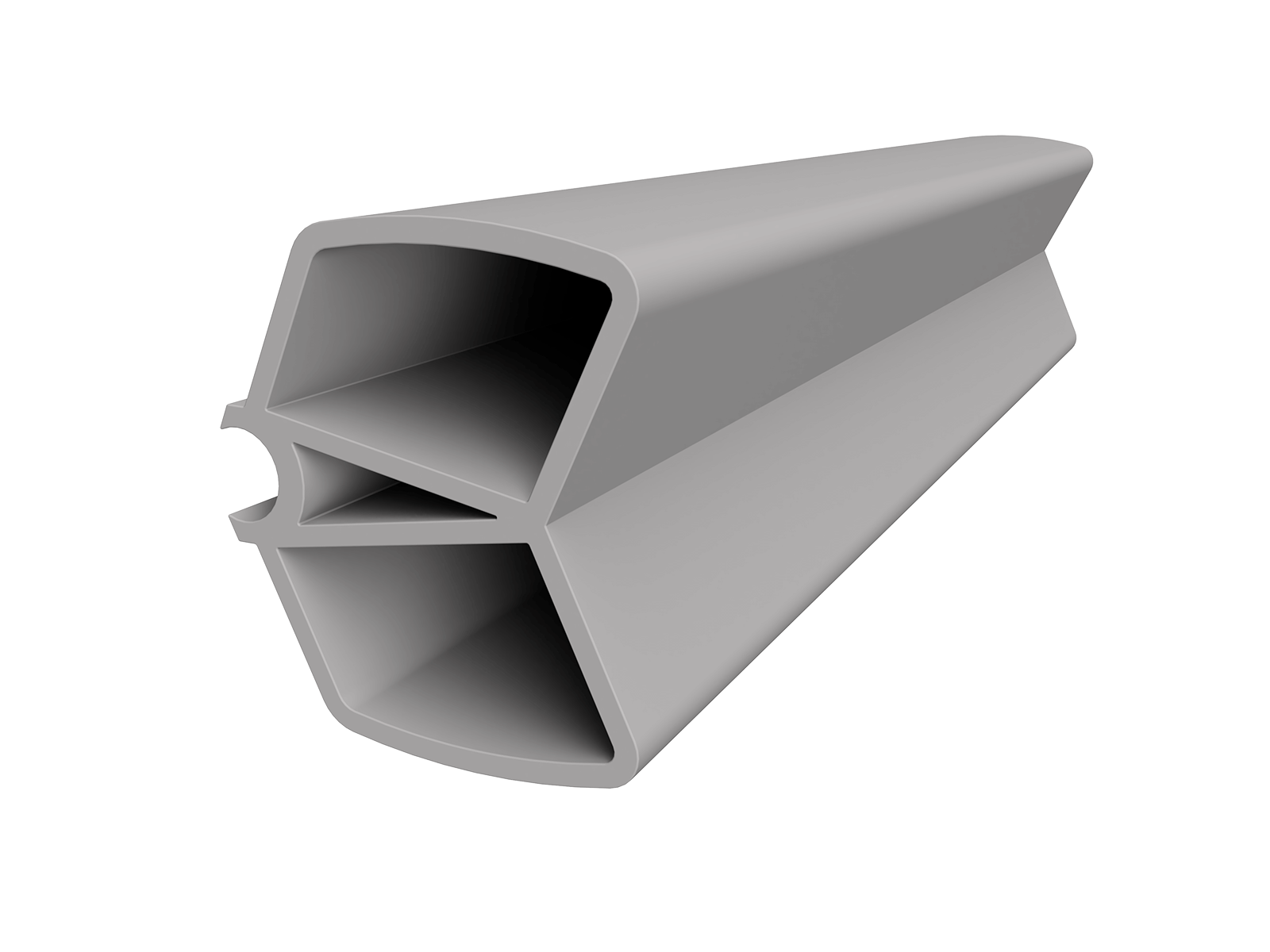

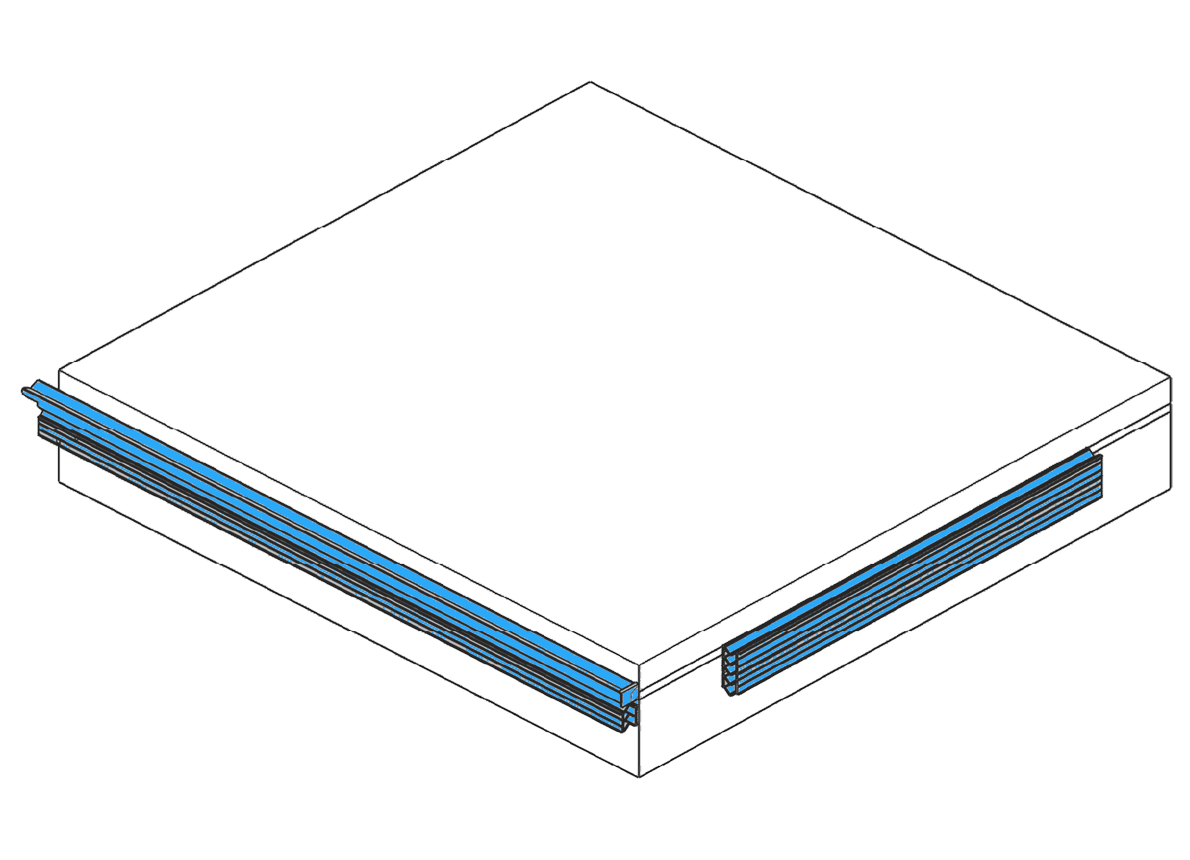

Horizontal Seals Installed in In Plant

Horizontal Seals Installed in On-Site

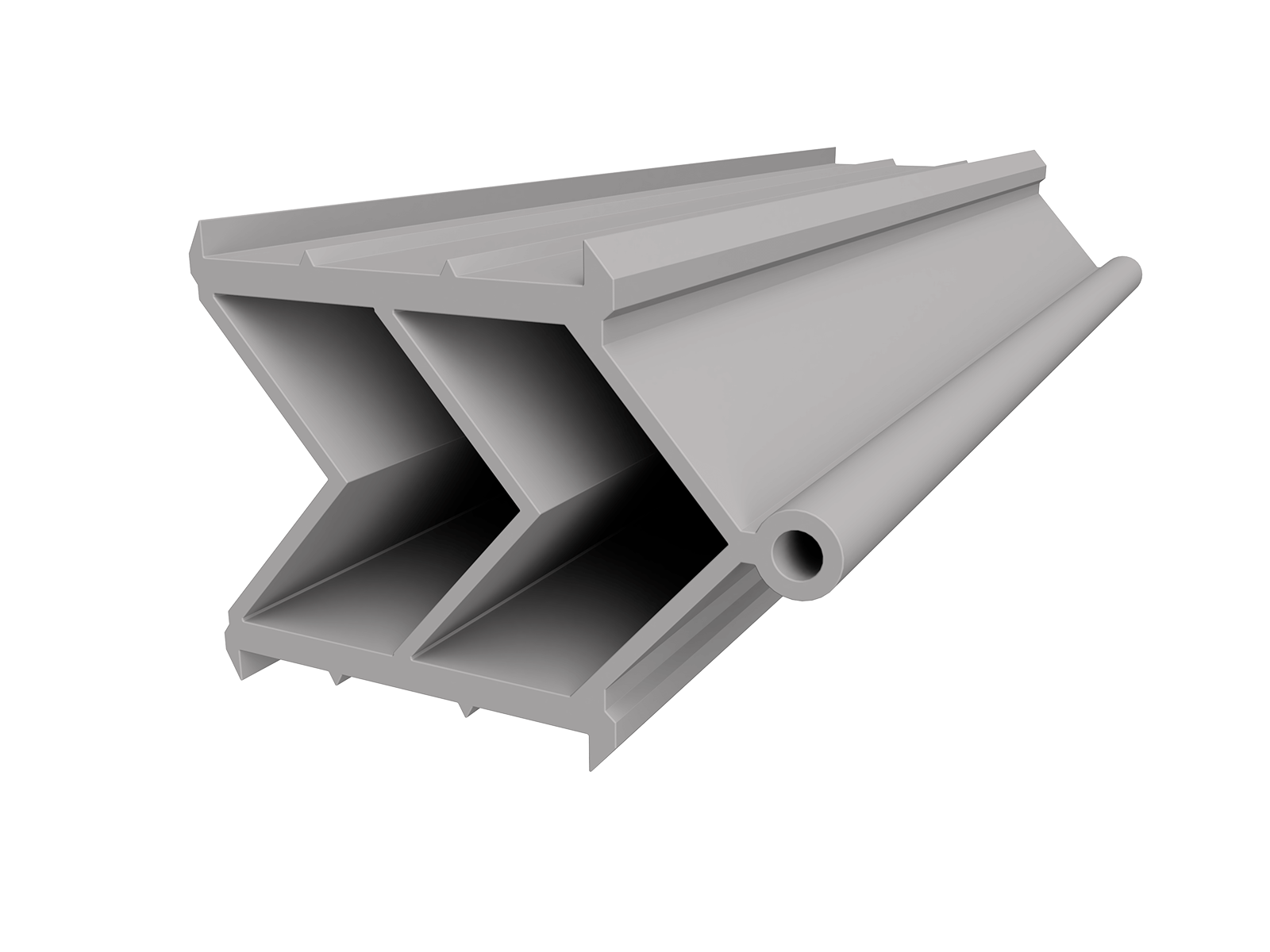

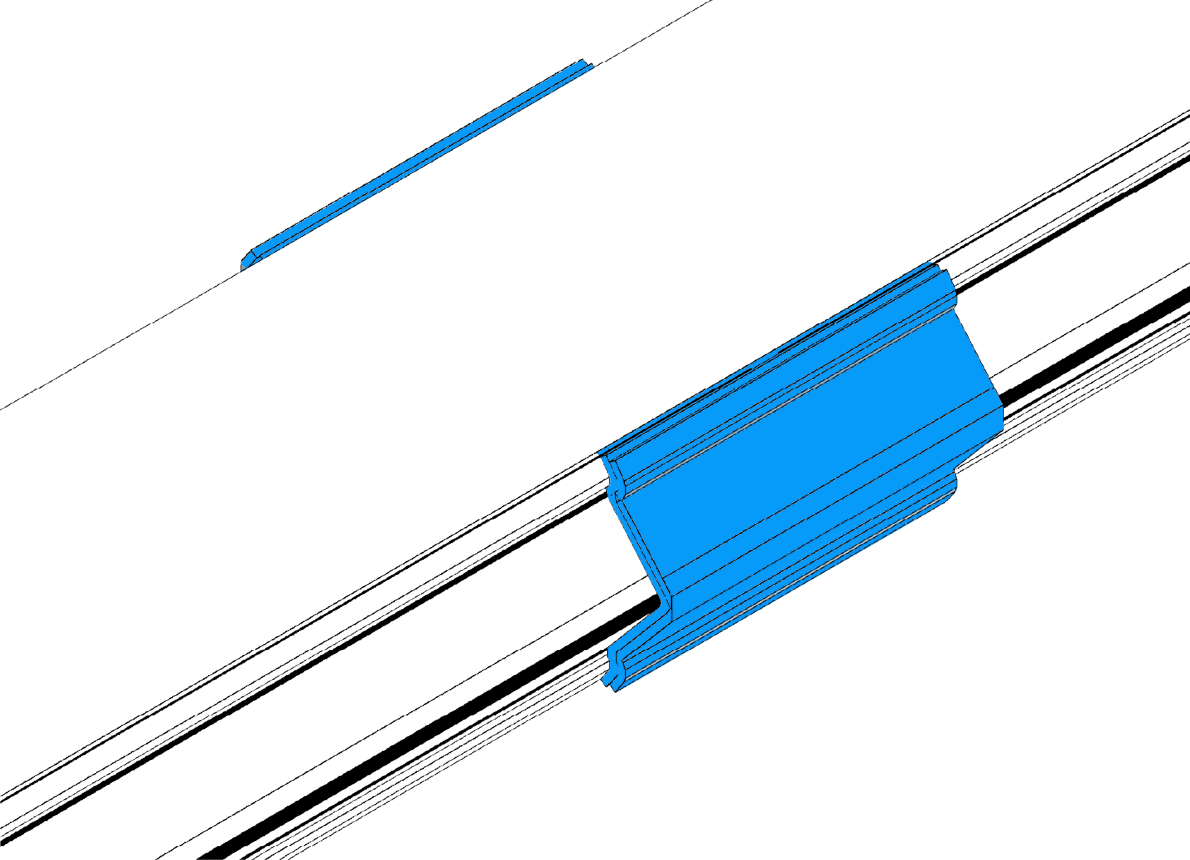

Exoskeletal Seal Splice – Outside Face

Exoskeletal Seal Splice – Inside Face

Installation

Over 90% of the iSEAL EP system is shop installed. The horizontal and vertical seals are shop installed. 3-way and 4-way joints are installed in the field as panels are set. All joints to be installed by qualified technicians.

The horizontal joint at the panel below and the vertical joint at the panel edge are filled with sealant to the top of the depth gage. The panel is then set using the patented Torpedo alignment system to ensure accurate alignment of the iSEAL EP system with adjacent panels. Finally, the Exoskeletal Seal splice is installed at 3-way and 4-way splices.

Follow us on Social Media