As construction methods evolve to meet the demands of speed, efficiency, and quality control, prefabrication has emerged as a leading strategy across commercial and multifamily sectors. One material stands out in this shift: cold-formed steel (CFS). Its consistency, strength, and compatibility with engineered systems make it ideal for streamlined, repeatable construction—and The Steel Network (TSN) is helping lead the charge.

The Demand for Faster, Safer Building Methods

Labor shortages, rising material costs, and tight project timelines have driven builders to seek more efficient methods. Prefabrication—whether in the form of panelized wall systems, floor assemblies, or modular components—offers a compelling solution. It brings construction into a controlled environment, reducing jobsite variables and improving installation speed.

Cold-formed steel is a natural match for this approach. It is:

- Non-combustible and ideal for fire-rated assemblies

- Dimensionally stable, resisting warping and shrinking

- Lightweight and high-strength, allowing for easy transport and installation

These properties enable predictable assembly and high repeatability—core principles of successful prefab construction.

Non-combustible and ideal for fire-rated assemblies

Dimensionally stable, resisting warping and shrinking

Lightweight and high-strength, allowing for easy transport and installation

These properties enable predictable assembly and high repeatability—core principles of successful prefab construction.

Componentized Framing: Where TSN Fits In

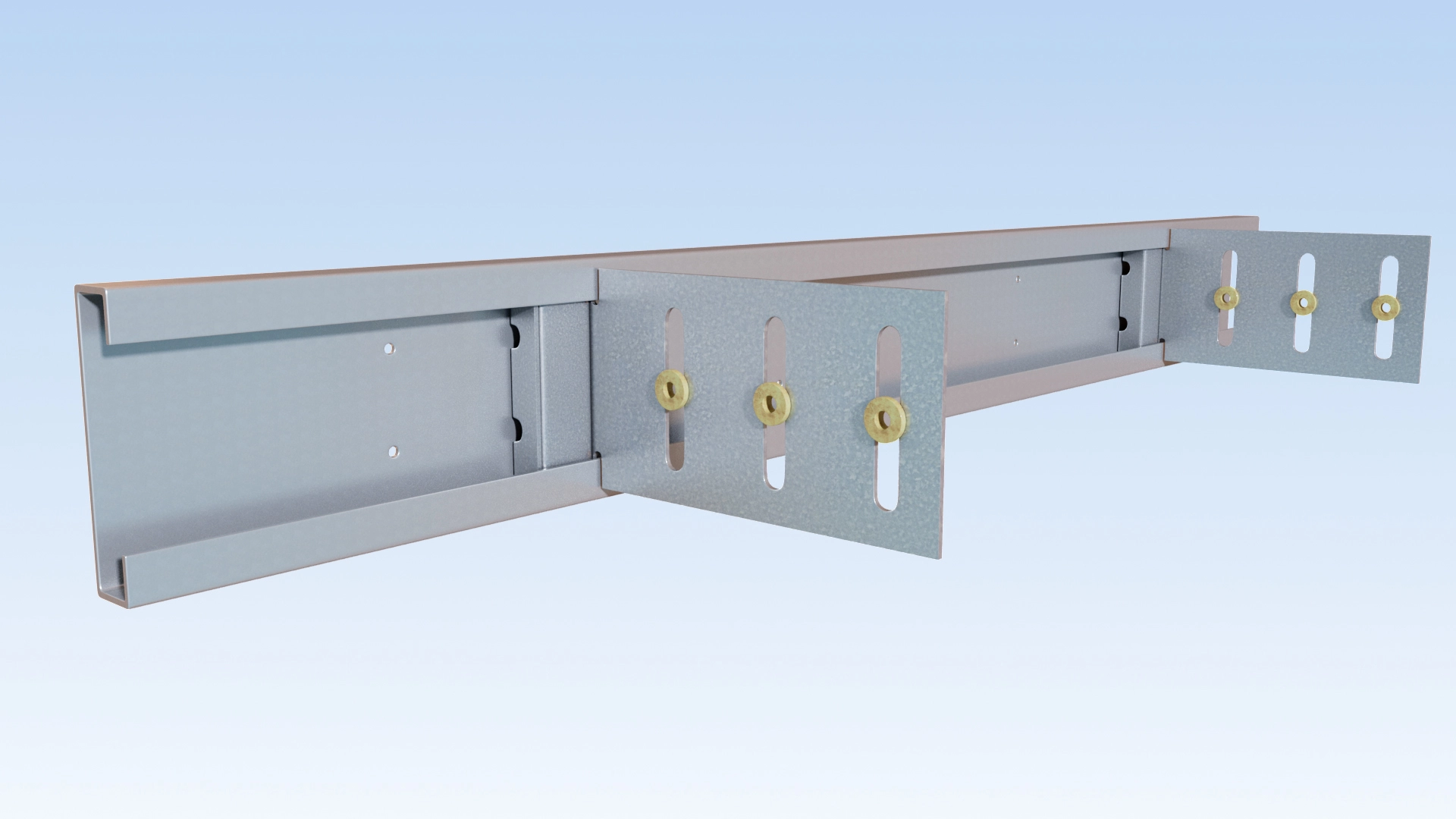

Prefabrication depends on more than just framing members—it relies on well-designed connections that ensure structural continuity and accommodate building movement. TSN manufactures an extensive range of cold-formed steel components specifically designed for:

- Deflection and drift (e.g., VertiClip® and DriftTrak® systems)

- Shear transfer and tension anchorage

- Load-bearing and curtain wall applications

These products are engineered for structural performance and code compliance, while also simplifying installation—whether in a shop environment or on-site.

Benefits of Using TSN Components in Prefabricated Assemblies

When used in panelized or modular systems, TSN’s connectors deliver distinct advantages:

- Reduced layout errors with precision-manufactured hardware

- Faster field installation thanks to pre-configured attachment points

- Improved quality control, as components are tested and designed for specific load demands

By incorporating TSN product lines, such as VertiClip®, DriftTrak®, or StiffClip® into prefabricated assemblies, contractors can create systems that not only meet structural requirements but also streamline the build process.

A Smarter Way to Frame

As prefabrication becomes more widely adopted, the demand for engineered, proven, and install-friendly solutions will only grow. The Steel Network is proud to support this shift through innovation, product development, and technical excellence.

Explore TSN’s full catalog of cold-formed steel framing solutions to see how your next project can benefit from prefab-ready components.