Light Steel Framing Products / Curtain Wall Members / Curtain Wall Stud

Curtain Wall Stud

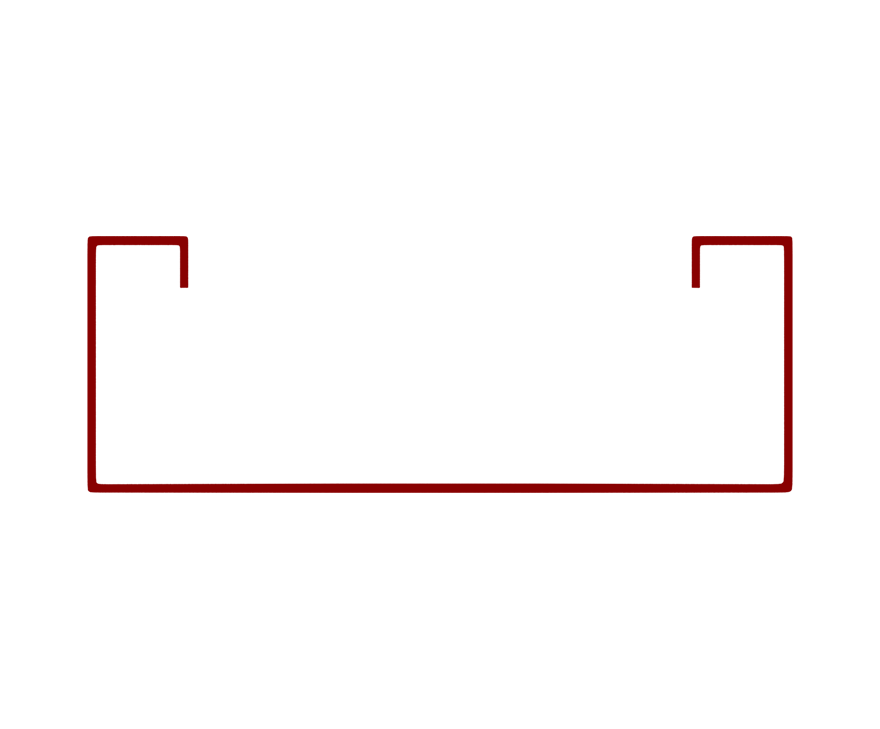

Curtain Wall Stud is an innovative addition to the light gauge steel stud industry, producing significant economies in both design and installation when compared with conventional “C” shaped studs. Curtain Wall stud’s configuration is similar to that of TSN’s JamStud® and delivers increased strength and stiffness compared to standard stud members when constructing exterior wall framing. Curtain Wall Stud’s shape is easily differentiated from the typical c-shape, enabling the selection of the most optimal member sizes.

Features

- Increases load capacity over a standard “C-shaped” stud of the same thickness

- Reduces overall materials used by allowing increased stud spacing

- Lighter weight results in easier handling & shipping efficiencies

- Increased load capacity enables selection of optimal thickness of curtain wall studs

- Increased stiffness for deflection

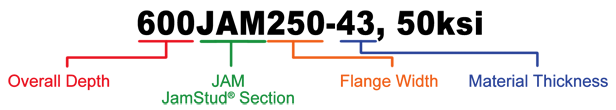

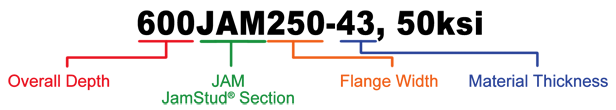

Nomenclature

Material Composition

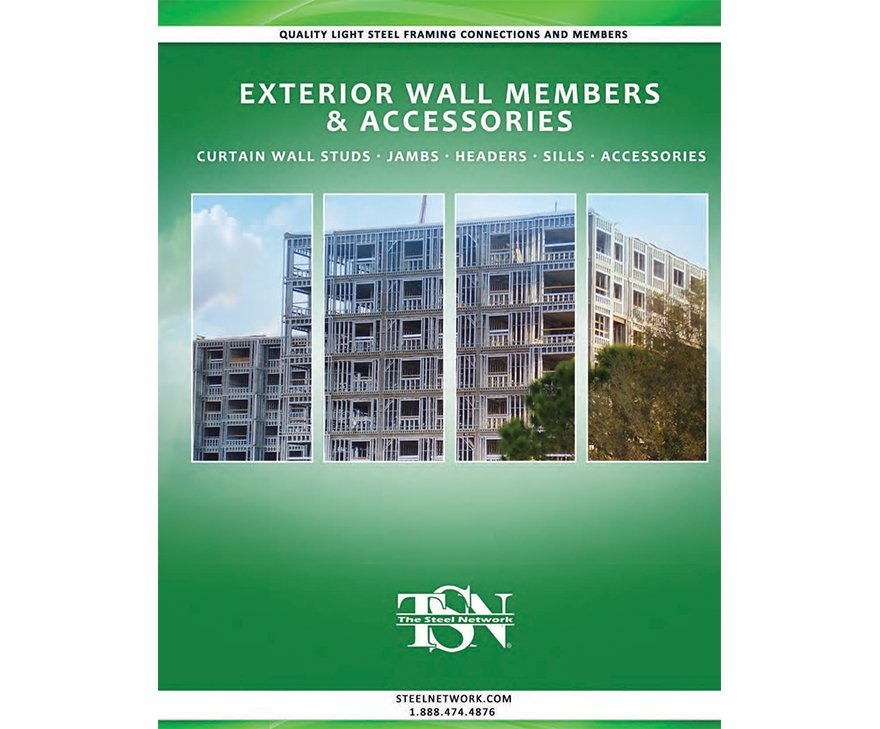

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. Curtain Wall Stud can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

Curtain Wall Stud Downloads

Curtain Wall Stud Applications

Window Jams, Headers, & Sils

Curtain Wall Stud Design Information

- JamStud Profile

- Gross Properties

- Effective Properties

- Allowable Heights 5-20 psf

- Allowable Heights 25-35 psf

|

|

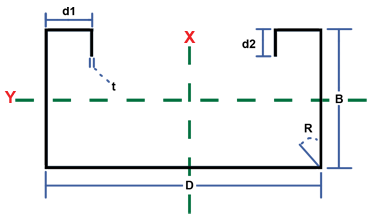

| Curtain Wall Stud Product Profile | |||||||

| Section (All 50 ksi) |

Overall Depth | Flange Width | Return Lip 1 | Return Lip 2 | Inside Bend | Design Thickness | Unit Weight |

| D | B | d1 | d2 | R | t | (lbs/ft) | |

| (in) | (in) | (in) | (in) | (in) | (in) | ||

| 362C162-33, 33 ksi | 3.625 | 1.625 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.004 |

| 362C162-43, 50 ksi | 3.625 | 1.625 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.304 |

| 362C162-54, 50 ksi | 3.625 | 1.625 | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.629 |

| 362C200-33, 33 ksi | 3.625 | 2 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.093 |

| 362C200-43, 50 ksi | 3.625 | 2 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.419 |

| 362C200-54, 50 ksi | 3.625 | 2 | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.773 |

| 600C162-33, 33 ksi | 6 | 1.625 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.284 |

| 600C162-43, 50 ksi | 6 | 1.625 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.668 |

| 600C162-54, 50 ksi | 6 | 1.625 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.086 |

| 600C200-33, 33 ksi | 6 | 2 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.372 |

| 600C200-43, 50 ksi | 6 | 2 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.783 |

| 600C200-54, 50 ksi | 6 | 2 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.231 |

| 800C162-33, 33 ksi | 8 | 1.625 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.52 |

| 800C162-43, 50 ksi | 8 | 1.625 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.975 |

| 800C162-54, 50 ksi | 8 | 1.625 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.472 |

| 800C200-33, 33 ksi | 8 | 2 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.608 |

| 800C200-43, 50 ksi | 8 | 2 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.09 |

| 800C200-54, 50 ksi | 8 | 2 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.616 |

Notes:

- Effective properties incorporate the strength increase from the cold-work of forming as applicable per AISI S100-16 Spec, Sec A3.3.2 (3).

- Tabulated gross properties are based on the full-unreduced cross section of the studs, away from punchouts.

- Allowable moment is the lesser of Mal and Mad. Stud distortional buckling is based on an assumed kΦ = 0.

- For deflection calculations, use the effective moment of inertia.

- The effective moment of inertia for deflection is calculated at a stress which results in a section modulus such that the stress times the section modulus at that stress is equal to the allowable moment. AISI S100-16 Spec Procedure I for serviceability determination has been used.

| Curtain Wall Stud Section Properties | |||||||||||||||

| Section | Design Thickness | Gross Properties | Torsional Properties | ||||||||||||

| Area | Weight | Ix | Sx | Rx | y | Sy | Ry | Jx1000 | Cw | Xo | Ro | ß | m | ||

| (in) | (in2) | (lbs/ft) | (in4) | (in3) | (in) | (in4) | (in3) | (in) | (in4) | (in6) | (in) | (in) | (in) | ||

| 362C162-33, 33 ksi | 0.0346 | 0.295 | 1.004 | 0.599 | 0.331 | 1.425 | 0.120 | 0.121 | 0.638 | 0.118 | 0.468 | -1.578 | 2.220 | 0.495 | 0.978 |

| 362C162-43, 50 ksi | 0.0451 | 0.383 | 1.304 | 0.771 | 0.425 | 1.419 | 0.154 | 0.156 | 0.635 | 0.260 | 0.605 | -1.573 | 2.211 | 0.494 | 0.975 |

| 362C162-54, 50 ksi | 0.0566 | 0.479 | 1.629 | 0.954 | 0.526 | 1.412 | 0.191 | 0.193 | 0.631 | 0.511 | 0.751 | -1.566 | 2.201 | 0.494 | 0.973 |

| 362C200-33, 33 ksi | 0.0346 | 0.321 | 1.093 | 0.683 | 0.377 | 1.459 | 0.196 | 0.164 | 0.782 | 0.128 | 0.759 | -1.954 | 2.561 | 0.418 | 1.186 |

| 362C200-43, 50 ksi | 0.0451 | 0.417 | 1.419 | 0.879 | 0.485 | 1.452 | 0.253 | 0.212 | 0.779 | 0.283 | 0.983 | -1.948 | 2.552 | 0.417 | 1.184 |

| 362C200-54, 50 ksi | 0.0566 | 0.521 | 1.773 | 1.089 | 0.601 | 1.445 | 0.313 | 0.263 | 0.775 | 0.556 | 1.224 | -1.942 | 2.542 | 0.416 | 1.182 |

| 600C162-33, 33 ksi | 0.0346 | 0.377 | 1.284 | 1.983 | 0.661 | 2.293 | 0.145 | 0.129 | 0.619 | 0.151 | 1.177 | -1.298 | 2.706 | 0.770 | 0.833 |

| 600C162-43, 50 ksi | 0.0451 | 0.490 | 1.668 | 2.562 | 0.854 | 2.286 | 0.186 | 0.166 | 0.616 | 0.332 | 1.515 | -1.292 | 2.697 | 0.770 | 0.830 |

| 600C162-54, 50 ksi | 0.0566 | 0.613 | 2.086 | 3.183 | 1.061 | 2.279 | 0.230 | 0.205 | 0.612 | 0.655 | 1.876 | -1.286 | 2.687 | 0.771 | 0.828 |

| 600C200-33, 33 ksi | 0.0346 | 0.403 | 1.372 | 2.214 | 0.738 | 2.343 | 0.237 | 0.174 | 0.766 | 0.161 | 1.907 | -1.636 | 2.959 | 0.694 | 1.029 |

| 600C200-43, 50 ksi | 0.0451 | 0.524 | 1.783 | 2.862 | 0.954 | 2.337 | 0.305 | 0.225 | 0.763 | 0.355 | 2.462 | -1.631 | 2.950 | 0.694 | 1.027 |

| 600C200-54, 50 ksi | 0.0566 | 0.656 | 2.231 | 3.558 | 1.186 | 2.330 | 0.378 | 0.280 | 0.759 | 0.700 | 3.057 | -1.624 | 2.940 | 0.695 | 1.025 |

| 800C162-33, 33 ksi | 0.0346 | 0.447 | 1.520 | 3.964 | 0.991 | 2.980 | 0.158 | 0.132 | 0.595 | 0.178 | 2.135 | -1.137 | 3.244 | 0.877 | 0.747 |

| 800C162-43, 50 ksi | 0.0451 | 0.580 | 1.975 | 5.130 | 1.282 | 2.973 | 0.203 | 0.170 | 0.592 | 0.394 | 2.747 | -1.131 | 3.235 | 0.878 | 0.745 |

| 800C162-54, 50 ksi | 0.0566 | 0.726 | 2.472 | 6.386 | 1.597 | 2.965 | 0.251 | 0.211 | 0.588 | 0.776 | 3.399 | -1.125 | 3.226 | 0.878 | 0.742 |

| 800C200-33, 33 ksi | 0.0346 | 0.472 | 1.608 | 4.376 | 1.094 | 3.043 | 0.260 | 0.179 | 0.742 | 0.189 | 3.459 | -1.449 | 3.451 | 0.824 | 0.934 |

| 800C200-43, 50 ksi | 0.0451 | 0.614 | 2.090 | 5.665 | 1.416 | 3.037 | 0.335 | 0.232 | 0.738 | 0.416 | 4.461 | -1.443 | 3.442 | 0.824 | 0.932 |

| 800C200-54, 50 ksi | 0.0566 | 0.769 | 2.616 | 7.056 | 1.764 | 3.030 | 0.415 | 0.288 | 0.735 | 0.821 | 5.535 | -1.437 | 3.433 | 0.825 | 0.929 |

| Section | Design Thickness | Effective Properties | |||||||||||||

| Solid Web | Punched Web | ||||||||||||||

| Ix | Sx | Ma | Va | Ycg | Iy1 | Mya1 | Iy1 | Mya1 | Ix | Sx | Ma | Va | Ycg | ||

| (in) | (in4) | (in3) | (in-k) | (lb) | (in) | (in4) | (in-k) | (in4) | (in-k) | (in4) | (in3) | (in-k) | (lb) | (in) | |

| 362C162-33, 33 ksi | 0.0346 | 0.599 | 0.330 | 6.521 | 1024 | 1.814 | 0.120 | 2.909 | 0.105 | 2.208 | 0.599 | 0.316 | 6.243 | 506 | 1.844 |

| 362C162-43, 50 ksi | 0.0451 | 0.771 | 0.425 | 13.897 | 2141 | 1.813 | 0.154 | 5.709 | 0.139 | 4.348 | 0.771 | 0.409 | 12.260 | 802 | 1.837 |

| 362C162-54, 50 ksi | 0.0566 | 0.954 | 0.526 | 17.481 | 3372 | 1.813 | 0.191 | 7.287 | 0.184 | 5.560 | 0.954 | 0.514 | 15.391 | 994 | 1.820 |

| 362C200-33, 33 ksi | 0.0346 | 0.683 | 0.352 | 6.958 | 1024 | 1.861 | 0.196 | 3.934 | 0.171 | 2.975 | 0.683 | 0.336 | 6.632 | 506 | 1.901 |

| 362C200-43, 50 ksi | 0.0451 | 0.879 | 0.463 | 13.851 | 2141 | 1.846 | 0.253 | 7.737 | 0.226 | 5.870 | 0.879 | 0.444 | 13.303 | 802 | 1.877 |

| 362C200-54, 50 ksi | 0.0566 | 1.089 | 0.601 | 17.986 | 3372 | 1.813 | 0.313 | 9.899 | 0.301 | 7.523 | 1.089 | 0.589 | 17.621 | 994 | 1.819 |

| 600C162-33, 33 ksi | 0.0346 | 1.983 | 0.660 | 13.035 | 644 | 3.002 | 0.145 | 3.082 | 0.110 | 2.234 | 1.983 | 0.660 | 13.035 | 644 | 3.002 |

| 600C162-43, 50 ksi | 0.0451 | 2.562 | 0.854 | 27.892 | 1432 | 3.000 | 0.186 | 6.053 | 0.146 | 4.404 | 2.562 | 0.854 | 27.892 | 1235 | 3.000 |

| 600C162-54, 50 ksi | 0.0566 | 3.183 | 1.061 | 35.250 | 2843 | 3.000 | 0.230 | 7.733 | 0.198 | 5.660 | 3.183 | 1.061 | 35.250 | 1942 | 3.000 |

| 600C200-33, 33 ksi | 0.0346 | 2.213 | 0.697 | 13.781 | 644 | 3.064 | 0.237 | 4.184 | 0.179 | 3.009 | 2.213 | 0.697 | 13.781 | 644 | 3.064 |

| 600C200-43, 50 ksi | 0.0451 | 2.862 | 0.916 | 27.438 | 1432 | 3.045 | 0.305 | 8.233 | 0.237 | 5.943 | 2.862 | 0.916 | 27.438 | 1235 | 3.045 |

| 600C200-54, 50 ksi | 0.0566 | 3.558 | 1.186 | 35.509 | 2843 | 3.000 | 0.378 | 10.540 | 0.322 | 7.655 | 3.558 | 1.186 | 35.509 | 1942 | 3.000 |

| 800C162-33, 33 ksi | 0.0346 | 3.757 | 0.840 | 16.593 | 478 | 4.351 | 0.158 | 3.162 | 0.112 | 2.244 | 3.757 | 0.840 | 16.593 | 478 | 4.351 |

| 800C162-43, 50 ksi | 0.0451 | 4.892 | 1.103 | 33.028 | 1060 | 4.320 | 0.203 | 6.211 | 0.149 | 4.425 | 4.892 | 1.103 | 33.028 | 1060 | 4.320 |

| 800C162-54, 50 ksi | 0.0566 | 6.229 | 1.439 | 43.084 | 2102 | 4.222 | 0.251 | 7.937 | 0.204 | 5.696 | 6.229 | 1.439 | 43.084 | 2102 | 4.222 |

| 800C200-33, 33 ksi | 0.0346 | 4.374 | 0.931 | 18.392 | 478 | 4.293 | 0.260 | 4.302 | 0.182 | 3.021 | 4.374 | 0.931 | 18.392 | 478 | 4.293 |

| 800C200-43, 50 ksi | 0.0451 | 5.665 | 1.255 | 37.584 | 1060 | 4.218 | 0.335 | 8.467 | 0.241 | 5.970 | 5.665 | 1.255 | 37.584 | 1060 | 4.218 |

| 800C200-54, 50 ksi | 0.0566 | 7.056 | 1.764 | 52.813 | 2102 | 4.000 | 0.415 | 10.842 | 0.330 | 7.702 | 7.056 | 1.764 | 52.813 | 2102 | 4.000 |

| Allowable Height for CW Sections – 1 Span (IBC 2009/ AISI S100-07 – IBC 2012/ AISI S100-07 with S2/10) | |||||||||||

| Section | Fy | Spacing | 5 psf | 15 psf | 20 psf | ||||||

| (ksi) | (in) o.c. | L/120 | L/240 | L/360 | L/240 | L/360 | L/600 | L/240 | L/360 | L/600 | |

| 362C162-33 | 33 | 12 | 25′ 0″ d | 19′ 10″ d | 17′ 4″ d | 15′ 6″ d | 13′ 6″ d | 11′ 5″ d | 14′ 0″ f | 12′ 3″ d | 10′ 4″ d |

| 362C162-33 | 33 | 16 | 22′ 9″ d | 18′ 0″ d | 15′ 9″ d | 14′ 0″ f | 12′ 3″ d | 10′ 4″ d | 12′ 1″ f e | 11′ 2″ d | 9′ 5″ d |

| 362C162-33 | 33 | 24 | 19′ 10″ f | 15′ 9″ d | 13′ 9″ d | 11′ 5″ f e | 10′ 9″ d e | 9′ 0″ d | 9′ 11″ f e | 9′ 9″ d e | 8′ 2″ d e |

| 362C162-43 | 50 | 12 | 27′ 2″ d | 21′ 7″ d | 18′ 10″ d | 16′ 10″ d | 14′ 8″ d | 12′ 5″ d | 15′ 4″ d | 13′ 4″ d | 11′ 3″ d |

| 362C162-43 | 50 | 16 | 24′ 9″ d | 19′ 7″ d | 17′ 1″ d | 15′ 4″ d | 13′ 4″ d | 11′ 3″ d | 13′ 11″ d | 12′ 2″ d | 10′ 3″ d |

| 362C162-43 | 50 | 24 | 21′ 7″ d | 17′ 1″ d | 14′ 11″ d | 13′ 4″ d | 11′ 8″ d | 9′ 10″ d | 12′ 2″ d | 10′ 7″ d | 8′ 11″ d |

| 362C162-54 | 50 | 12 | 29′ 2″ d | 23′ 2″ d | 20′ 3″ d | 18′ 1″ d | 15′ 9″ d | 13′ 4″ d | 16′ 5″ d | 14′ 4″ d | 12′ 1″ d |

| 362C162-54 | 50 | 16 | 26′ 6″ d | 21′ 1″ d | 18′ 5″ d | 16′ 5″ d | 14′ 4″ d | 12′ 1″ d | 14′ 11″ d | 13′ 0″ d | 11′ 0″ d |

| 362C162-54 | 50 | 24 | 23′ 2″ d | 18′ 5″ d | 16′ 1″ d | 14′ 4″ d | 12′ 6″ d | 10′ 7″ d | 13′ 0″ d | 11′ 4″ d | 9′ 7″ d |

| 362C200-33 | 33 | 12 | 26′ 1″ d | 20′ 9″ d | 18′ 1″ d | 16′ 2″ d | 14′ 1″ d | 11′ 11″ d | 14′ 6″ f | 12′ 10″ d | 10′ 10″ d |

| 362C200-33 | 33 | 16 | 23′ 9″ d | 18′ 10″ d | 16′ 5″ d | 14′ 6″ f | 12′ 10″ d | 10′ 10″ d | 12′ 7″ f e | 11′ 8″ d | 9′ 10″ d |

| 362C200-33 | 33 | 24 | 20′ 7″ f | 16′ 5″ d | 14′ 4″ d | 11′ 10″ f e | 11′ 2″ d e | 9′ 5″ d | 10′ 3″ f e | 10′ 2″ d e | 8′ 7″ d e |

| 362C200-43 | 50 | 12 | 28′ 5″ d | 22′ 7″ d | 19′ 8″ d | 17′ 7″ d | 15′ 4″ d | 12′ 11″ d | 16′ 0″ d | 14′ 0″ d | 11′ 9″ d |

| 362C200-43 | 50 | 16 | 25′ 10″ d | 20′ 6″ d | 17′ 11″ d | 16′ 0″ d | 14′ 0″ d | 11′ 9″ d | 14′ 6″ d | 12′ 8″ d | 10′ 8″ d |

| 362C200-43 | 50 | 24 | 22′ 7″ d | 17′ 11″ d | 15′ 7″ d | 14′ 0″ d | 12′ 2″ d | 10′ 3″ d | 12′ 8″ d | 11′ 1″ d | 9′ 4″ d |

| 362C200-54 | 50 | 12 | 30′ 6″ d | 24′ 3″ d | 21′ 2″ d | 18′ 11″ d | 16′ 6″ d | 13′ 11″ d | 17′ 2″ d | 15′ 0″ d | 12′ 8″ d |

| 362C200-54 | 50 | 16 | 27′ 9″ d | 22′ 0″ d | 19′ 3″ d | 17′ 2″ d | 15′ 0″ d | 12′ 8″ d | 15′ 7″ d | 13′ 7″ d | 11′ 6″ d |

| 362C200-54 | 50 | 24 | 24′ 3″ d | 19′ 3″ d | 16′ 9″ d | 15′ 0″ d | 13′ 1″ d | 11′ 0″ d | 13′ 7″ d | 11′ 11″ d | 10′ 0″ d |

| 600C162-33 | 33 | 12 | 37′ 3″ d | 29′ 7″ d | 25′ 10″ d | 22′ 6″ f e | 20′ 2″ d e | 17′ 0″ d | 19′ 6″ f e | 18′ 4″ d e | 15′ 5″ d e |

| 600C162-33 | 33 | 16 | 33′ 9″ f | 26′ 10″ d | 23′ 6″ d | 19′ 6″ f e | 18′ 4″ d e | 15′ 5″ d e | 16′ 10″ f e | 16′ 8″ d e | 14′ 0″ d e |

| 600C162-33 | 33 | 24 | 27′ 7″ f | 23′ 6″ d | 20′ 6″ d | 15′ 11″ f e | 15′ 11″ f e | 13′ 6″ d e | 13′ 9″ f e | 13′ 9″ f e | 12′ 3″ d e |

| 600C162-43 | 50 | 12 | 40′ 7″ d | 32′ 3″ d | 28′ 2″ d | 25′ 2″ d | 22′ 0″ d | 18′ 6″ d | 22′ 10″ d | 19′ 11″ d | 16′ 10″ d |

| 600C162-43 | 50 | 16 | 36′ 11″ d | 29′ 3″ d | 25′ 7″ d | 22′ 10″ d | 19′ 11″ d | 16′ 10″ d | 20′ 9″ d | 18′ 2″ d | 15′ 3″ d |

| 600C162-43 | 50 | 24 | 32′ 3″ d | 25′ 7″ d | 22′ 4″ d | 19′ 11″ d | 17′ 5″ d | 14′ 8″ d | 18′ 2″ d | 15′ 10″ d | 13′ 4″ d |

| 600C162-54 | 50 | 12 | 43′ 8″ d | 34′ 8″ d | 30′ 3″ d | 27′ 1″ d | 23′ 7″ d | 19′ 11″ d | 24′ 7″ d | 21′ 5″ d | 18′ 1″ d |

| 600C162-54 | 50 | 16 | 39′ 8″ d | 31′ 6″ d | 27′ 6″ d | 24′ 7″ d | 21′ 5″ d | 18′ 1″ d | 22′ 4″ d | 19′ 6″ d | 16′ 5″ d |

| 600C162-54 | 50 | 24 | 34′ 8″ d | 27′ 6″ d | 24′ 0″ d | 21′ 5″ d | 18′ 9″ d | 15′ 10″ d | 19′ 6″ d | 17′ 0″ d | 14′ 4″ d |

| 600C200-33 | 33 | 12 | 38′ 8″ d | 30′ 8″ d | 26′ 10″ d | 23′ 1″ f e | 20′ 11″ d e | 17′ 8″ d | 20′ 0″ f e | 19′ 0″ d e | 16′ 0″ d e |

| 600C200-33 | 33 | 16 | 34′ 7″ f | 27′ 11″ d | 24′ 4″ d | 20′ 0″ f e | 19′ 0″ d e | 16′ 0″ d e | 17′ 3″ f e | 17′ 3″ f e | 14′ 7″ d e |

| 600C200-33 | 33 | 24 | 28′ 3″ f | 24′ 4″ d | 21′ 3″ d | 16′ 4″ f e | 16′ 4″ f e | 14′ 0″ d e | 14′ 1″ f e | 14′ 1″ f e | 12′ 8″ d e |

| 600C200-43 | 50 | 12 | 42′ 2″ d | 33′ 5″ d | 29′ 2″ d | 26′ 1″ d | 22′ 10″ d | 19′ 3″ d | 23′ 8″ d | 20′ 8″ d | 17′ 5″ d |

| 600C200-43 | 50 | 16 | 38′ 3″ d | 30′ 4″ d | 26′ 6″ d | 23′ 8″ d | 20′ 8″ d | 17′ 5″ d | 21′ 6″ d | 18′ 10″ d | 15′ 10″ d |

| 600C200-43 | 50 | 24 | 33′ 5″ d | 26′ 6″ d | 23′ 2″ d | 20′ 8″ d | 18′ 1″ d | 15′ 3″ d | 18′ 10″ d e | 16′ 5″ d | 13′ 10″ d |

| 600C200-54 | 50 | 12 | 45′ 4″ d | 35′ 11″ d | 31′ 5″ d | 28′ 1″ d | 24′ 6″ d | 20′ 8″ d | 25′ 6″ d | 22′ 3″ d | 18′ 9″ d |

| 600C200-54 | 50 | 16 | 41′ 2″ d | 32′ 8″ d | 28′ 6″ d | 25′ 6″ d | 22′ 3″ d | 18′ 9″ d | 23′ 2″ d | 20′ 3″ d | 17′ 1″ d |

| 600C200-54 | 50 | 24 | 35′ 11″ d | 28′ 6″ d | 24′ 11″ d | 22′ 3″ d | 19′ 5″ d | 16′ 5″ d | 20′ 3″ d | 17′ 8″ d | 14′ 11″ d |

| 800C162-33 | 33 | 12 | 45′ 7″ f | 37′ 1″ d | 32′ 6″ d | 26′ 3″ f e | 25′ 3″ d e | 21′ 5″ d e | 22′ 9″ f e | 22′ 9″ f e | 19′ 5″ d e |

| 800C162-33 | 33 | 16 | 39′ 5″ f | 33′ 8″ d | 29′ 6″ d | 22′ 9″ f e | 22′ 9″ f e | 19′ 5″ d e | 19′ 8″ f e | 19′ 8″ f e | 17′ 7″ d e |

| 800C162-33 | 33 | 24 | 32′ 2″ f e | 29′ 4″ d e | 25′ 8″ d | 18′ 7″ f e | 18′ 7″ f e | 16′ 11″ d e | 16′ 1″ f e | 16′ 1″ f e | 15′ 4″ d e |

| 800C162-43 | 50 | 12 | 51′ 0″ d | 40′ 7″ d | 35′ 6″ d | 31′ 8″ d | 27′ 8″ d | 23′ 4″ d | 28′ 9″ d | 25′ 2″ d | 21′ 3″ d |

| 800C162-43 | 50 | 16 | 46′ 3″ d | 36′ 11″ d | 32′ 3″ d | 28′ 9″ d | 25′ 2″ d | 21′ 3″ d | 26′ 1″ d | 22′ 10″ d | 19′ 3″ d |

| 800C162-43 | 50 | 24 | 40′ 4″ d | 32′ 2″ d | 28′ 2″ d | 25′ 1″ d e | 21′ 11″ d | 18′ 6″ d | 22′ 1″ f e | 19′ 11″ d e | 16′ 10″ d |

| 800C162-54 | 50 | 12 | 55′ 1″ d | 43′ 8″ d | 38′ 2″ d | 34′ 1″ d | 29′ 10″ d | 25′ 2″ d | 31′ 0″ d | 27′ 1″ d | 22′ 10″ d |

| 800C162-54 | 50 | 16 | 50′ 0″ d | 39′ 8″ d | 34′ 8″ d | 31′ 0″ d | 27′ 1″ d | 22′ 10″ d | 28′ 2″ d | 24′ 7″ d | 20′ 9″ d |

| 800C162-54 | 50 | 24 | 43′ 8″ d | 34′ 8″ d | 30′ 3″ d | 27′ 1″ d | 23′ 8″ d | 19′ 11″ d | 24′ 7″ d | 21′ 6″ d | 18′ 1″ d |

| 800C200-33 | 33 | 12 | 46′ 9″ f | 38′ 6″ d | 33′ 8″ d | 27′ 0″ f e | 26′ 3″ d e | 22′ 2″ d e | 23′ 4″ f e | 23′ 4″ f e | 20′ 1″ d e |

| 800C200-33 | 33 | 16 | 40′ 6″ f | 35′ 0″ d | 30′ 7″ d | 23′ 4″ f e | 23′ 4″ f e | 20′ 1″ d e | 20′ 3″ f e | 20′ 3″ f e | 18′ 3″ d e |

| 800C200-33 | 33 | 24 | 33′ 0″ f e | 30′ 7″ d e | 26′ 8″ d | 19′ 1″ f e | 19′ 1″ f e | 17′ 7″ d e | 16′ 6″ f e | 16′ 6″ f e | 16′ 0″ d e |

| 800C200-43 | 50 | 12 | 52′ 11″ d | 42′ 0″ d | 36′ 8″ d | 32′ 9″ d | 28′ 8″ d | 24′ 2″ d | 29′ 9″ d | 26′ 0″ d | 21′ 11″ d |

| 800C200-43 | 50 | 16 | 48′ 1″ d | 38′ 2″ d | 33′ 4″ d | 29′ 9″ d | 26′ 0″ d | 21′ 11″ d | 27′ 1″ d e | 23′ 8″ d | 19′ 11″ d |

| 800C200-43 | 50 | 24 | 42′ 0″ d | 33′ 4″ d | 29′ 1″ d | 26′ 0″ d e | 22′ 9″ d | 19′ 2″ d | 22′ 8″ f e | 20′ 8″ d e | 17′ 5″ d |

| 800C200-54 | 50 | 12 | 56′ 11″ d | 45′ 2″ d | 39′ 6″ d | 35′ 3″ d | 30′ 10″ d | 26′ 0″ d | 32′ 1″ d | 28′ 0″ d | 23′ 7″ d |

| 800C200-54 | 50 | 16 | 51′ 9″ d | 41′ 1″ d | 35′ 10″ d | 32′ 1″ d | 28′ 0″ d | 23′ 7″ d | 29′ 1″ d | 25′ 5″ d | 21′ 5″ d |

| 800C200-54 | 50 | 24 | 45′ 2″ d | 35′ 10″ d | 31′ 4″ d | 28′ 0″ d | 24′ 5″ d | 20′ 7″ d | 25′ 5″ d | 22′ 2″ d | 18′ 9″ d |

Table Notes:

- “f”: flexure controls, “d”: deflection controls.

- The values in this catalog are based on the 2007 edition of North American Specification for the Design of Cold-Formed Steel Structural Members, AISI S100-07 as referenced by 2009 International Building Code (IBC) and AISI S100-07 with supplement S2-10 as referenced by 2012 IBC.

- Distortional buckling calculations are based on Kφ = 0.

- Listed wind pressures represent 1.0 W calculated based on 2009 IBC or 0.6 W calculated based on 2012 IBC. For deflection calculations, listed wind pressures, have been reduced by 0.70 as allowed by IBC. The 5 psf pressure has not been reduced for deflection checks.

- Studs must be braced against rotation and lateral movement at all supports.

- Studs are assumed to be adequately braced at a maximum spacing of Lu to develop full allowable moment.

- Web crippling check is based on 1″ of bearing at end supports and 3″ of bearing at interior support.

- Moment of inertia for deflection is optimized based on the maximum moment at service loads for the listed spans; therefore; span values may be greater than spans based on an effective moment of inertia listed in section property tables.

| Allowable Height for CW Sections – 1 Span (IBC 2009/ AISI S100-07 – IBC 2012/ AISI S100-07 with S2/10) | ||||||||

| Section | Fy | Spacing | 40 psf | 50 psf | ||||

| (ksi) | (in) o.c. | L/240 | L/360 | L/600 | L/240 | L/360 | L/600 | |

| 362C162-33 | 33 | 12 | 9′ 11″ f e | 9′ 9″ d e | 8′ 2″ d e | 8′ 10″ f e | 8′ 10″ f e | 7′ 7″ d e |

| 362C162-33 | 33 | 16 | 8′ 7″ f e | 8′ 7″ f e | 7′ 5″ d e | 7′ 8″ f e | 7′ 8″ f e | 6′ 11″ d e |

| 362C162-33 | 33 | 24 | 7′ 0″ f e | 7′ 0″ f e | 6′ 6″ d e | 6′ 3″ f e | 6′ 3″ f e | 6′ 0″ d e |

| 362C162-43 | 50 | 12 | 12′ 2″ d | 10′ 7″ d | 8′ 11″ d | 11′ 3″ d | 9′ 10″ d | 8′ 3″ d |

| 362C162-43 | 50 | 16 | 11′ 0″ d | 9′ 7″ d | 8′ 1″ d | 10′ 3″ d | 8′ 11″ d | 7′ 6″ d |

| 362C162-43 | 50 | 24 | 9′ 7″ d | 8′ 5″ d | 7′ 1″ d | 8′ 10″ f e | 7′ 9″ d | 6′ 7″ d |

| 362C162-54 | 50 | 12 | 13′ 0″ d | 11′ 4″ d | 9′ 7″ d | 12′ 1″ d | 10′ 7″ d | 8′ 11″ d |

| 362C162-54 | 50 | 16 | 11′ 10″ d | 10′ 4″ d | 8′ 8″ d | 11′ 0″ d | 9′ 7″ d | 8′ 1″ d |

| 362C162-54 | 50 | 24 | 10′ 4″ d | 9′ 0″ d | 7′ 7″ d | 9′ 7″ d | 8′ 4″ d | 7′ 1″ d |

| 362C200-33 | 33 | 12 | 10′ 3″ f e | 10′ 2″ d e | 8′ 7″ d e | 9′ 2″ f e | 9′ 2″ f e | 7′ 11″ d e |

| 362C200-33 | 33 | 16 | 8′ 11″ f e | 8′ 11″ f e | 7′ 9″ d e | 7′ 11″ f e | 7′ 11″ f e | 7′ 3″ d e |

| 362C200-33 | 33 | 24 | 7′ 3″ f e | 7′ 3″ f e | 6′ 10″ d e | 6′ 6″ f e | 6′ 6″ f e | 6′ 4″ d e |

| 362C200-43 | 50 | 12 | 12′ 8″ d | 11′ 1″ d | 9′ 4″ d | 11′ 9″ d | 10′ 3″ d | 8′ 8″ d |

| 362C200-43 | 50 | 16 | 11′ 6″ d | 10′ 1″ d | 8′ 6″ d | 10′ 8″ d | 9′ 4″ d | 7′ 10″ d |

| 362C200-43 | 50 | 24 | 10′ 1″ d e | 8′ 9″ d | 7′ 5″ d | 9′ 2″ f e | 8′ 2″ d e | 6′ 10″ d |

| 362C200-54 | 50 | 12 | 13′ 7″ d | 11′ 11″ d | 10′ 0″ d | 12′ 8″ d | 11′ 0″ d | 9′ 4″ d |

| 362C200-54 | 50 | 16 | 12′ 4″ d | 10′ 10″ d | 9′ 1″ d | 11′ 6″ d | 10′ 0″ d | 8′ 5″ d |

| 362C200-54 | 50 | 24 | 10′ 10″ d | 9′ 5″ d | 7′ 11″ d | 10′ 0″ d | 8′ 9″ d | 7′ 4″ d |

| 600C162-33 | 33 | 12 | 13′ 9″ f e | 13′ 9″ f e | 12′ 3″ d e | 12′ 4″ f e | 12′ 4″ f e | 11′ 4″ d e |

| 600C162-33 | 33 | 16 | 11′ 11″ f e | 11′ 11″ f e | 11′ 1″ d e | 10′ 8″ f e | 10′ 8″ f e | 10′ 4″ d e |

| 600C162-33 | 33 | 24 | 9′ 9″ f e | 9′ 9″ f e | 9′ 9″ f e | 8′ 8″ f e | 8′ 8″ f e | 8′ 8″ f e |

| 600C162-43 | 50 | 12 | 18′ 2″ d | 15′ 10″ d | 13′ 4″ d | 16′ 10″ d e | 14′ 8″ d | 12′ 5″ d |

| 600C162-43 | 50 | 16 | 16′ 4″ f e | 14′ 5″ d e | 12′ 1″ d | 14′ 7″ f e | 13′ 4″ d e | 11′ 3″ d |

| 600C162-43 | 50 | 24 | 13′ 4″ f e | 12′ 7″ d e | 10′ 7″ d e | 11′ 11″ f e | 11′ 8″ d e | 9′ 10″ d e |

| 600C162-54 | 50 | 12 | 19′ 6″ d | 17′ 0″ d | 14′ 4″ d | 18′ 1″ d | 15′ 10″ d | 13′ 4″ d |

| 600C162-54 | 50 | 16 | 17′ 8″ d | 15′ 6″ d | 13′ 0″ d | 16′ 5″ d | 14′ 4″ d | 12′ 1″ d |

| 600C162-54 | 50 | 24 | 15′ 6″ f e | 13′ 6″ d | 11′ 5″ d | 13′ 11″ f e | 12′ 6″ d e | 10′ 7″ d |

| 600C200-33 | 33 | 12 | 14′ 1″ f e | 14′ 1″ f e | 12′ 8″ d e | 12′ 7″ f e | 12′ 7″ f e | 11′ 10″ d e |

| 600C200-33 | 33 | 16 | 12′ 3″ f e | 12′ 3″ f e | 11′ 7″ d e | 10′ 11″ f e | 10′ 11″ f e | 10′ 9″ d e |

| 600C200-33 | 33 | 24 | 10′ 0″ f e | 10′ 0″ f e | 10′ 0″ f e | 8′ 11″ f e | 8′ 11″ f e | 8′ 11″ f e |

| 600C200-43 | 50 | 12 | 18′ 10″ d e | 16′ 5″ d | 13′ 10″ d | 17′ 4″ f e | 15′ 3″ d e | 12′ 10″ d |

| 600C200-43 | 50 | 16 | 16′ 9″ f e | 14′ 11″ d e | 12′ 7″ d | 15′ 0″ f e | 13′ 10″ d e | 11′ 8″ d e |

| 600C200-43 | 50 | 24 | 13′ 8″ f e | 13′ 0″ d e | 11′ 0″ d e | 12′ 3″ f e | 12′ 1″ d e | 10′ 2″ d e |

| 600C200-54 | 50 | 12 | 20′ 3″ d | 17′ 8″ d | 14′ 11″ d | 18′ 9″ d | 16′ 5″ d | 13′ 10″ d |

| 600C200-54 | 50 | 16 | 18′ 4″ d | 16′ 1″ d | 13′ 6″ d | 17′ 1″ d | 14′ 11″ d | 12′ 7″ d |

| 600C200-54 | 50 | 24 | 15′ 11″ f e | 14′ 0″ d | 11′ 10″ d | 14′ 3″ f e | 13′ 0″ d e | 11′ 0″ d |

| 800C162-33 | 33 | 12 | 16′ 1″ f e | 16′ 1″ f e | 15′ 4″ d e | 14′ 5″ f e | 14′ 5″ f e | 14′ 3″ d e |

| 800C162-33 | 33 | 16 | 13′ 11″ f e | 13′ 11″ f e | 13′ 11″ f e | 12′ 5″ f e | 12′ 5″ f e | 12′ 5″ f e |

| 800C162-33 | 33 | 24 | 11′ 4″ f e | 11′ 4″ f e | 11′ 4″ f e | 9′ 6″ f e | 9′ 6″ f e | 9′ 6″ f e |

| 800C162-43 | 50 | 12 | 22′ 1″ f e | 19′ 11″ d e | 16′ 10″ d | 19′ 9″ f e | 18′ 6″ d e | 15′ 7″ d e |

| 800C162-43 | 50 | 16 | 19′ 1″ f e | 18′ 1″ d e | 15′ 3″ d e | 17′ 1″ f e | 16′ 9″ d e | 14′ 2″ d e |

| 800C162-43 | 50 | 24 | 15′ 7″ f e | 15′ 7″ f e | 13′ 4″ d e | 13′ 11″ f e | 13′ 11″ f e | 12′ 4″ d e |

| 800C162-54 | 50 | 12 | 24′ 7″ d | 21′ 6″ d | 18′ 1″ d | 22′ 10″ d e | 19′ 11″ d | 16′ 10″ d |

| 800C162-54 | 50 | 16 | 22′ 4″ d e | 19′ 6″ d | 16′ 5″ d | 20′ 0″ f e | 18′ 1″ d e | 15′ 3″ d |

| 800C162-54 | 50 | 24 | 18′ 3″ f e | 17′ 0″ d e | 14′ 4″ d e | 16′ 4″ f e | 15′ 10″ d e | 13′ 4″ d e |

| 800C200-33 | 33 | 12 | 16′ 6″ f e | 16′ 6″ f e | 16′ 0″ d e | 14′ 9″ f e | 14′ 9″ f e | 14′ 9″ f e |

| 800C200-33 | 33 | 16 | 14′ 3″ f e | 14′ 3″ f e | 14′ 3″ f e | 12′ 9″ f e | 12′ 9″ f e | 12′ 9″ f e |

| 800C200-33 | 33 | 24 | 11′ 8″ f e | 11′ 8″ f e | 11′ 8″ f e | 9′ 6″ f e | 9′ 6″ f e | 9′ 6″ f e |

| 800C200-43 | 50 | 12 | 22′ 8″ f e | 20′ 8″ d e | 17′ 5″ d | 20′ 3″ f e | 19′ 2″ d e | 16′ 2″ d e |

| 800C200-43 | 50 | 16 | 19′ 7″ f e | 18′ 9″ d e | 15′ 10″ d e | 17′ 6″ f e | 17′ 5″ d e | 14′ 8″ d e |

| 800C200-43 | 50 | 24 | 16′ 0″ f e | 16′ 0″ f e | 13′ 10″ d e | 14′ 4″ f e | 14′ 4″ f e | 12′ 10″ d e |

| 800C200-54 | 50 | 12 | 25′ 5″ d | 22′ 2″ d | 18′ 9″ d | 23′ 7″ d e | 20′ 7″ d | 17′ 5″ d |

| 800C200-54 | 50 | 16 | 23′ 0″ f e | 20′ 2″ d | 17′ 0″ d | 20′ 7″ f e | 18′ 9″ d e | 15′ 9″ d |

| 800C200-54 | 50 | 24 | 18′ 9″ f e | 17′ 7″ d e | 14′ 10″ d e | 16′ 9″ f e | 16′ 4″ d e | 13′ 9″ d e |

Follow us on Social Media