ThermaFast®

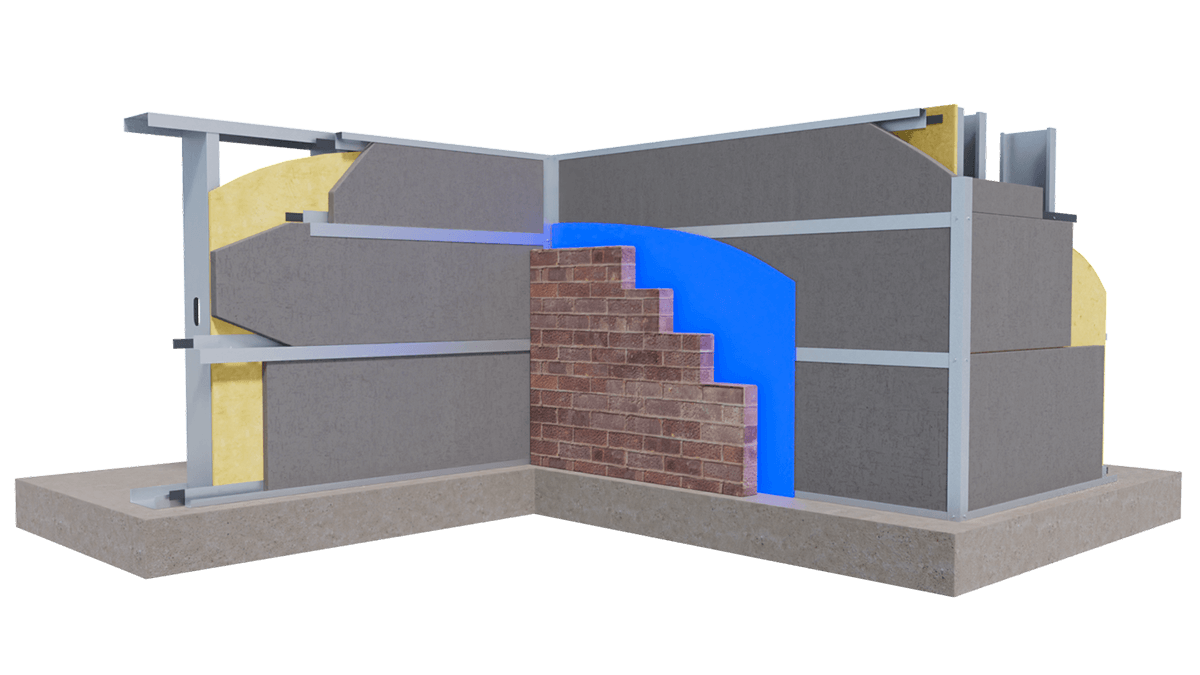

Recent changes in the IECC Energy Conservation Code and ASHRAE Standard 90.1 necessitate the installation of 1 to 4 inches of continuous rigid insulation layer on the outside surface of exterior metal stud walls. Existing building component systems lack sufficient accommodation for cladding assemblies, like cement board panels, siding, metal panels, EIFS, stucco, etc. since there is no viable means to attach to a stable substrate like plywood or gypsum sheathing over the thick rigid insulation layer other than long and unstable cantilevered screws.

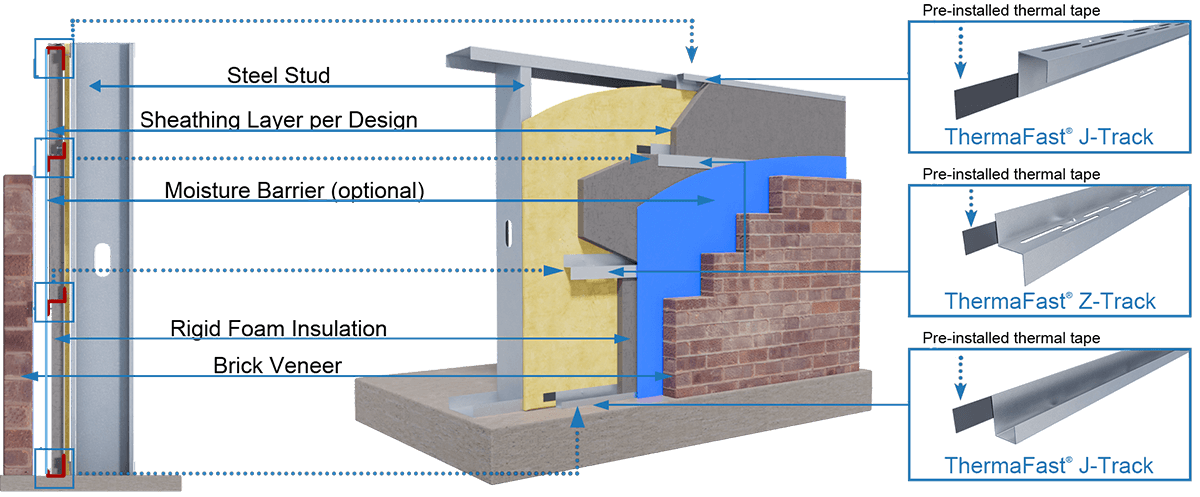

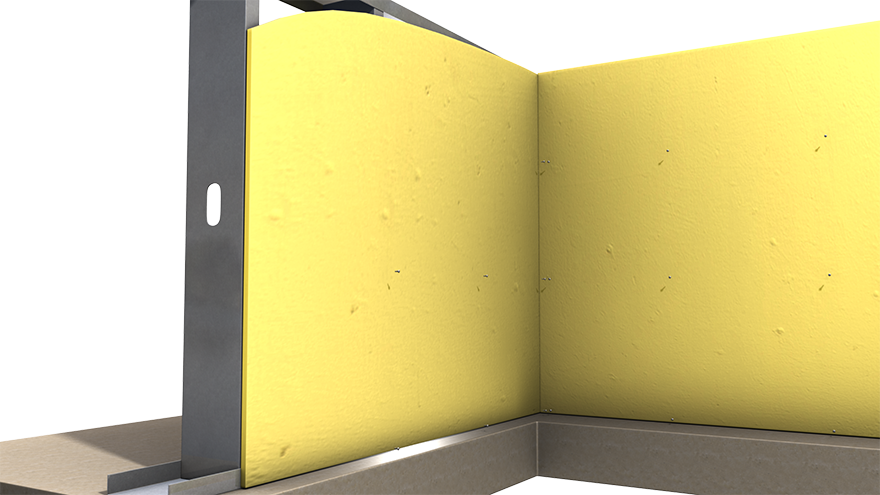

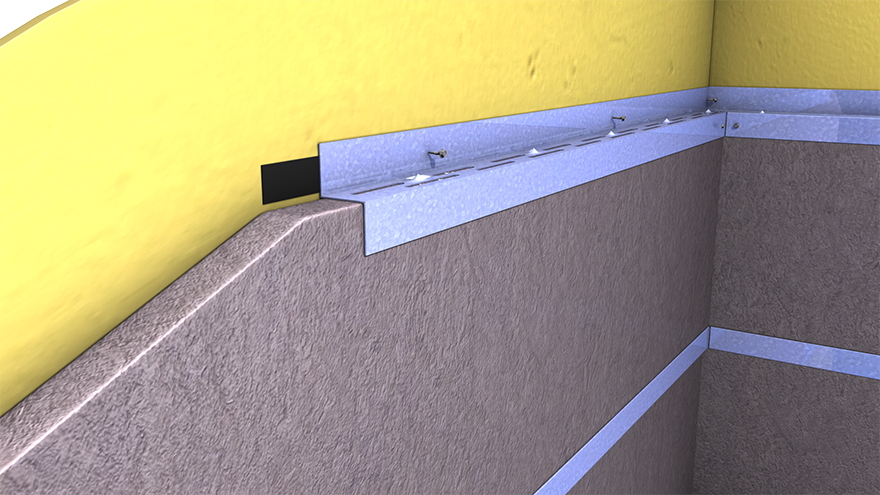

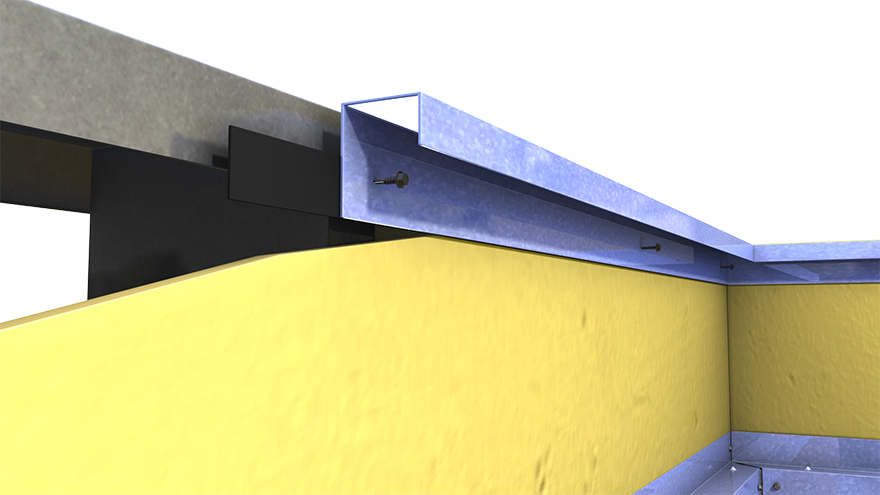

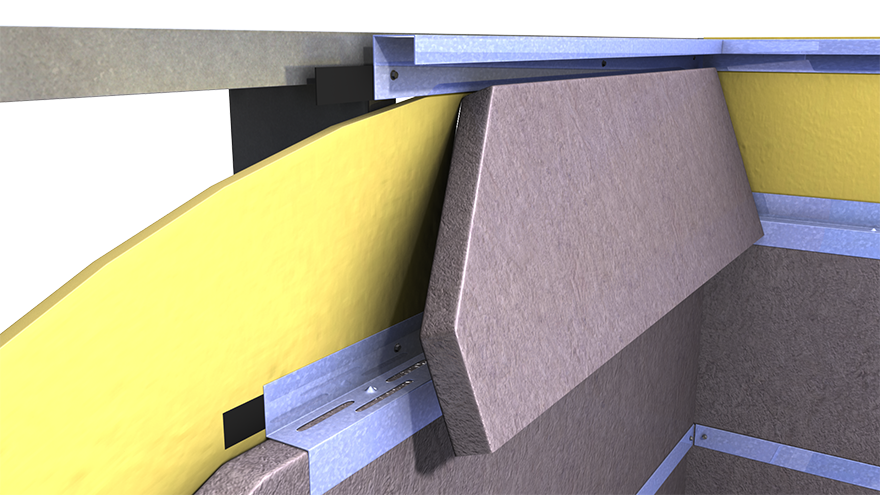

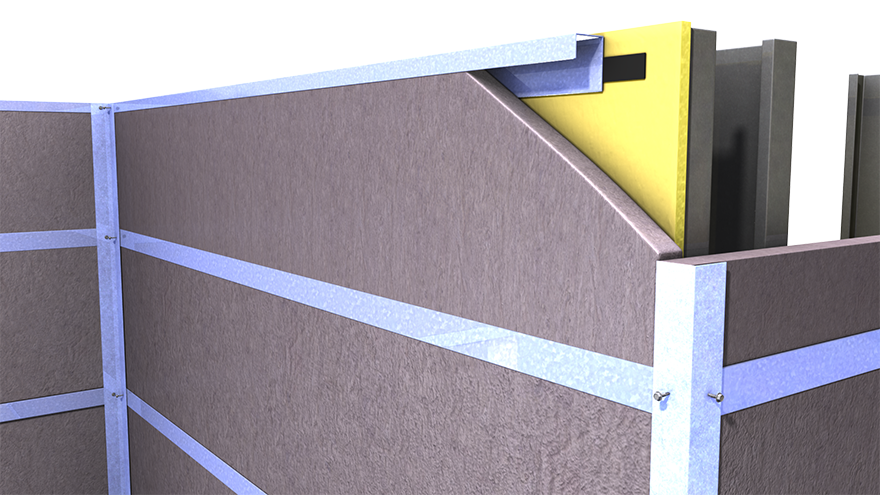

The ThermaFast Rigid Insulation Framing System is an engineered installer-friendly set of steel framing tracks and angles designed to be an integral part of the continuous rigid insulation, and at the same time provide a stable component for direct substrate attachment.

Features

- Pre-engineered framing system to support weight of rigid insulation, cladding material, and wind loads

- Unique foam engagement feature keeps rigid foam insulation from sliding or popping out of place without the need for specialty fasteners with washers

- Utilizes typical screws to attach the system

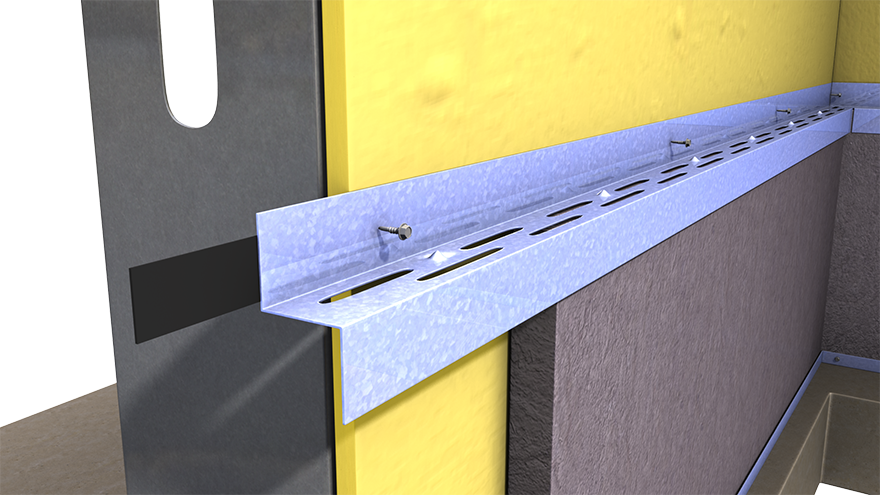

- Wide flanges for increased target area for screws when installing sheathing or alternative finishes

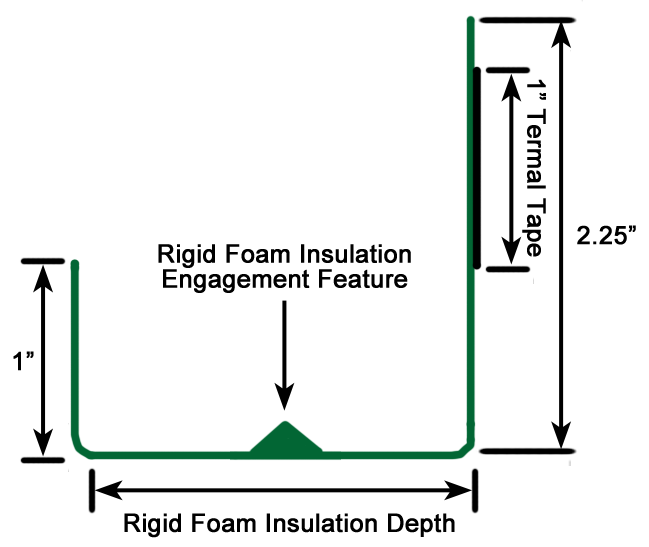

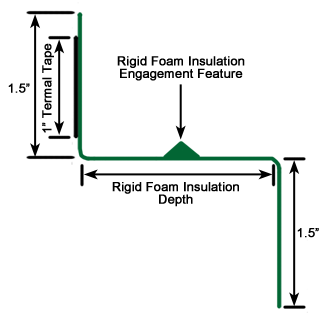

- 1″ thermal tape comes preinstalled to each track for an integrated thermal break between the steel studs and continuous insulation

- Mill-certified high strength steel and added galvanized coating layer

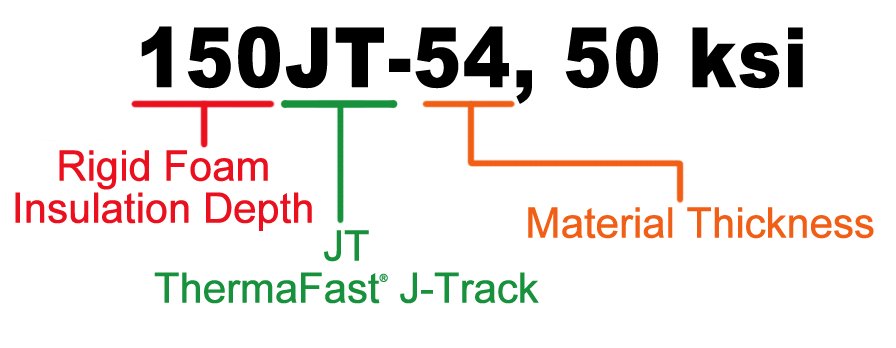

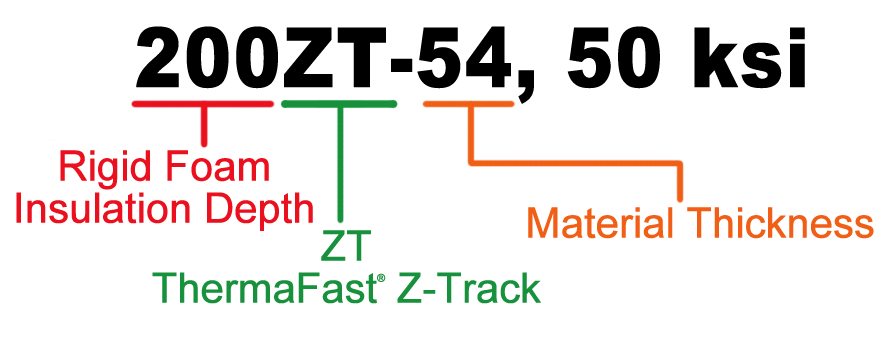

Order Information

Length

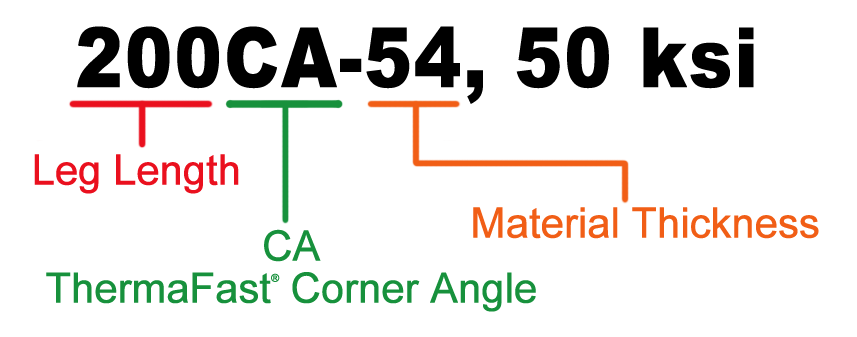

200CA-33, 50ksi

200CA-54, 50ksi

100ZT-33, 50ksi

150ZT-33, 50ksi

200ZT-33, 50ksi

300ZT-33, 50ksi

400ZT-33, 50ksi

100ZT-54, 50ksi

150ZT-54, 50ksi

200ZT-54, 50ksi

300ZT-54, 50ksi

400ZT-54, 50ksi

100JT-33, 50ksi

150JT-33, 50ksi

200JT-33, 50ksi

300JT-33, 50ksi

400JT-33, 50ksi

100JT-54, 50ksi

150JT-54, 50ksi

200JT-54, 50ksi

300JT-54, 50ksi

400JT-54, 50ksi

Qty/Skid

200CA-33, 50ksi

200CA-54, 50ksi

100ZT-33, 50ksi

150ZT-33, 50ksi

200ZT-33, 50ksi

300ZT-33, 50ksi

400ZT-33, 50ksi

100ZT-54, 50ksi

150ZT-54, 50ksi

200ZT-54, 50ksi

300ZT-54, 50ksi

400ZT-54, 50ksi

100JT-33, 50ksi

150JT-33, 50ksi

200JT-33, 50ksi

300JT-33, 50ksi

400JT-33, 50ksi

100JT-54, 50ksi

150JT-54, 50ksi

200JT-54, 50ksi

300JT-54, 50ksi

400JT-54, 50ksi

Lbs/Ft

200CA-33, 50ksi

200CA-54, 50ksi

100ZT-33, 50ksi

150ZT-33, 50ksi

200ZT-33, 50ksi

300ZT-33, 50ksi

400ZT-33, 50ksi

100ZT-54, 50ksi

150ZT-54, 50ksi

200ZT-54, 50ksi

300ZT-54, 50ksi

400ZT-54, 50ksi

100JT-33, 50ksi

150JT-33, 50ksi

200JT-33, 50ksi

300JT-33, 50ksi

400JT-33, 50ksi

100JT-54, 50ksi

150JT-54, 50ksi

200JT-54, 50ksi

300JT-54, 50ksi

400JT-54, 50ksi

Lbs/Skid

200CA-33, 50ksi

200CA-54, 50ksi

100ZT-33, 50ksi

150ZT-33, 50ksi

200ZT-33, 50ksi

300ZT-33, 50ksi

400ZT-33, 50ksi

100ZT-54, 50ksi

150ZT-54, 50ksi

200ZT-54, 50ksi

300ZT-54, 50ksi

400ZT-54, 50ksi

100JT-33, 50ksi

150JT-33, 50ksi

200JT-33, 50ksi

300JT-33, 50ksi

400JT-33, 50ksi

100JT-54, 50ksi

150JT-54, 50ksi

200JT-54, 50ksi

300JT-54, 50ksi

400JT-54, 50ksi

Material Composition

Metal: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi(450MPa) minimum tensile strength, with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating. Available in 33mil minimum thickness (20 gauge, 0.0346” design thickness) or 54mil minimum thickness (16 gauge, 0.0566” design thickness).

Thermal Tape: Thickness 1/16”, Density 25 lbs/ft³ (ASTM D3574), Thermal Conductivity k-factor 0.3 Btu-in/hour-ft²-oF (ASTM C-518)

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. ThermaFast® can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

ThermaFast® Downloads

Installation Instructions

1. Install sheathing as designed.

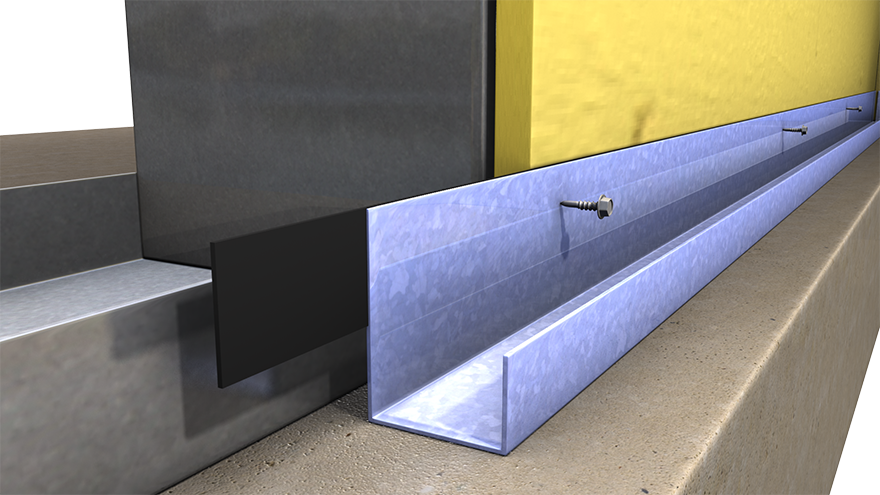

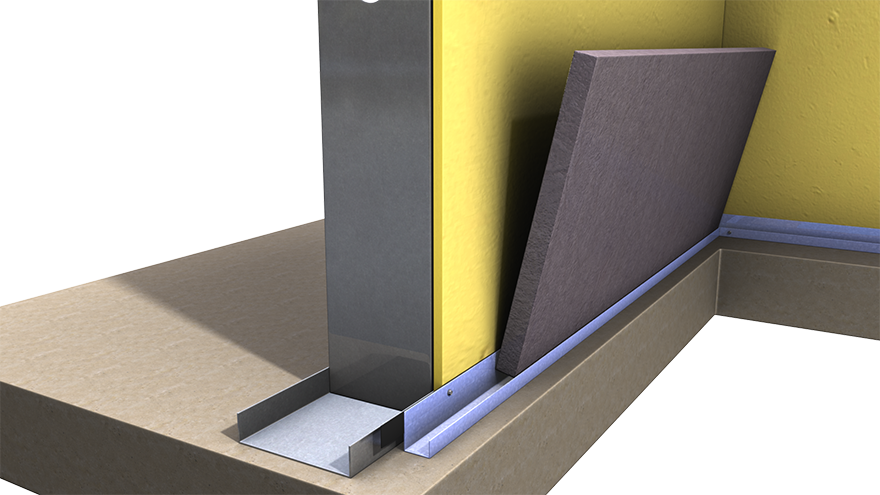

2. Install ThermaFast® J-Track at base of wall, connecting at each stud.

3. Insert 24" height rigid foam insulation.

4. Install ThermaFast® Z-Track at top of 24" rigid foam insulation, connecting at each stud.

5. Repeat steps 2 and 3 until head of wall is reached with rigid foam insulation.

6. Before placing top row of insulation, install J-Track at head of wall, connecting at each stud.

7. Insert top row of rigid insulation into previously installed J-Track at head of wall.

8. Install ThermaFast® Corner Angle, attaching to J and Z tracks.

J-Track Section Properties

(kips-in)

Z-Track Section Properties & Profile

(kips-in)

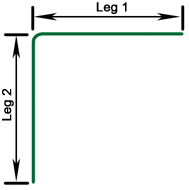

Corner Angle Profile

(ga)

(in)

(in)

(R)

(lbs/ft)

Thermal Resistances

This table provides thermal performance data (R- and U-values) of the ThermaFast® Rigid Insulation Framing System produced by the Steel Network Inc. The ThermaFast System is used in exterior wall assemblies to support rigid foam insulation with thicknesses ranging from 1.0 inch to 4.0 inch. In addition, the ThermaFast System provides viable means to attach the cladding assemblies, like cement board, siding, metal panels, to a stable substrate instead of using long and unstable cantilevered screws to the sheathing layer. This summary allows designers to have fast and straightforward access to information with sufficient accuracy to reduce uncertainty in the thermal performance of building envelope components. Thermal modelling for this project was completed using a 3D finite element analysis heat transfer software package by SolidWorks®; SW Thermal Solver and follows ASHRAE/IES Standard 90.1 requirements.

Follow us on Social Media