a³LiGN™

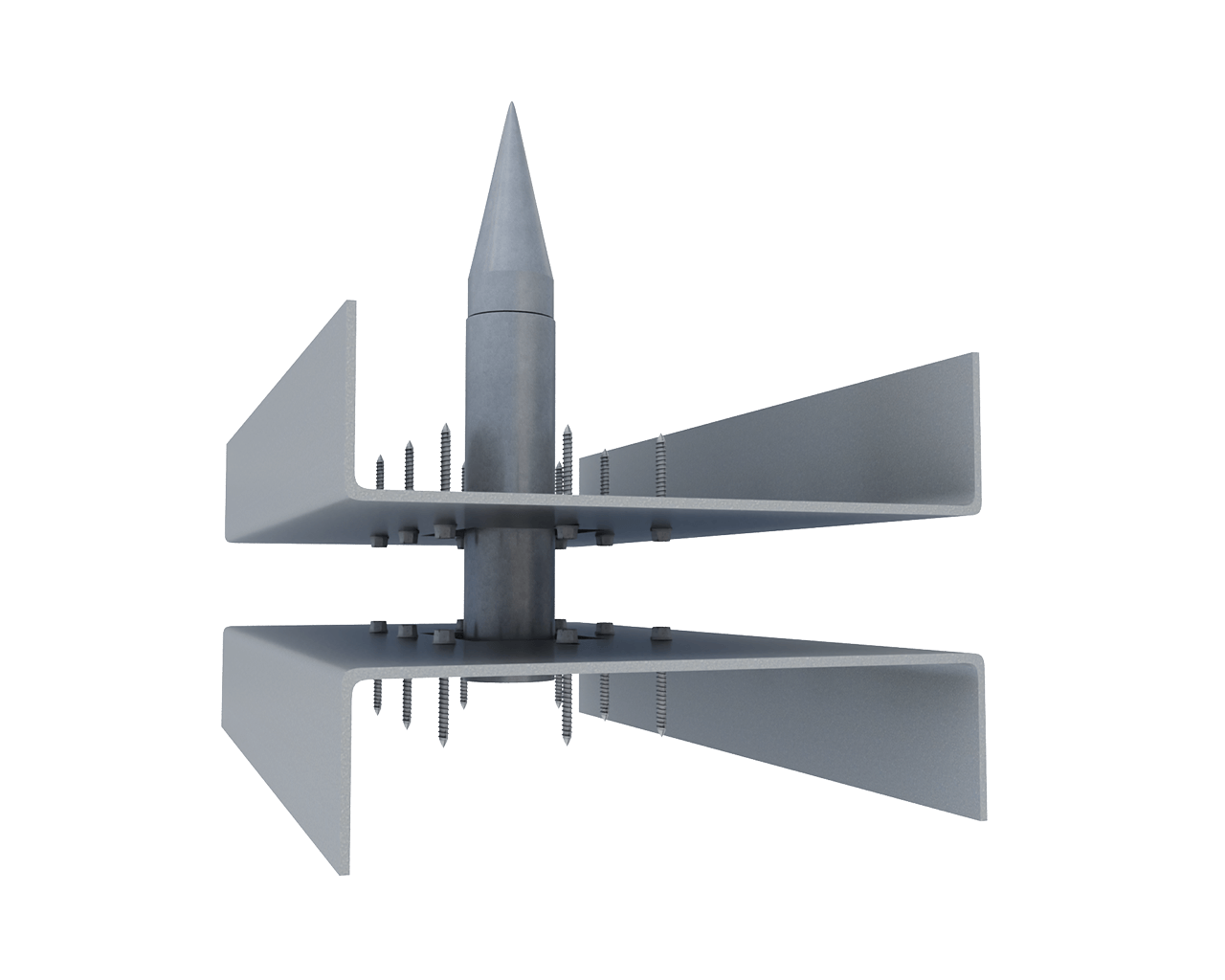

PeerEngine’s a³LiGN™, is a revolutionary alignment solution designed to streamline the installation of cold-formed steel wall panels for panelizers. This system facilitates vertical alignment through an innovative round pin/tube and slot mechanism pre-installed on the tops and bottoms of each panel. When hoisted by a crane, panels seamlessly slide over the pin and tube of the panel below, ensuring perfect alignment of the panel and exterior finish surfaces. The proprietary design also eliminates the use of welded assemblies and ensures that fasteners do not extend into the joint area, allowing for obstructed panel movement.

When wall panels are manufactured in a controlled environment, a³LiGN™ guarantees precision and reliability on the jobsite. This advanced system significantly reduces on-site installation time, leading to substantial cost savings and increased efficiency on the job site. By integrating a³LiGN™ into your panel installation process, you can achieve faster, more accurate panel alignment, enhancing overall productivity and project timelines.

*The Steel Network, Inc. (TSN) is the exclusive distributor for a³LiGN, by PeerEngine, LLC. For more warranty information, see PeerEngine’s a³LiGN™ Limited Warranty.

Material Composition

Plates: ASTM A1011 HSLAS Grade 50 Class 1 (Or Approved Equivalent), 50ksi (340

MPa) minimum yield strength, 65ksi (450 MPa) minimum tensile strength, 97mil or 118mil

minimum thickness (12 gauge, 0.1017” design thickness or 10 gauge, 0.1242″ design thickness)

with ASTM A653/653M G90 (Z275) hot dipped galvanized coating.

Pipe: ASTM A53 Grade B, 35ksi minimum yield strength, 60ksi minimum tensile strength,

0.1330″ nominal wall thickness, 0.1164″ minimum wall thickness, with shop coating or

approved equivalent.

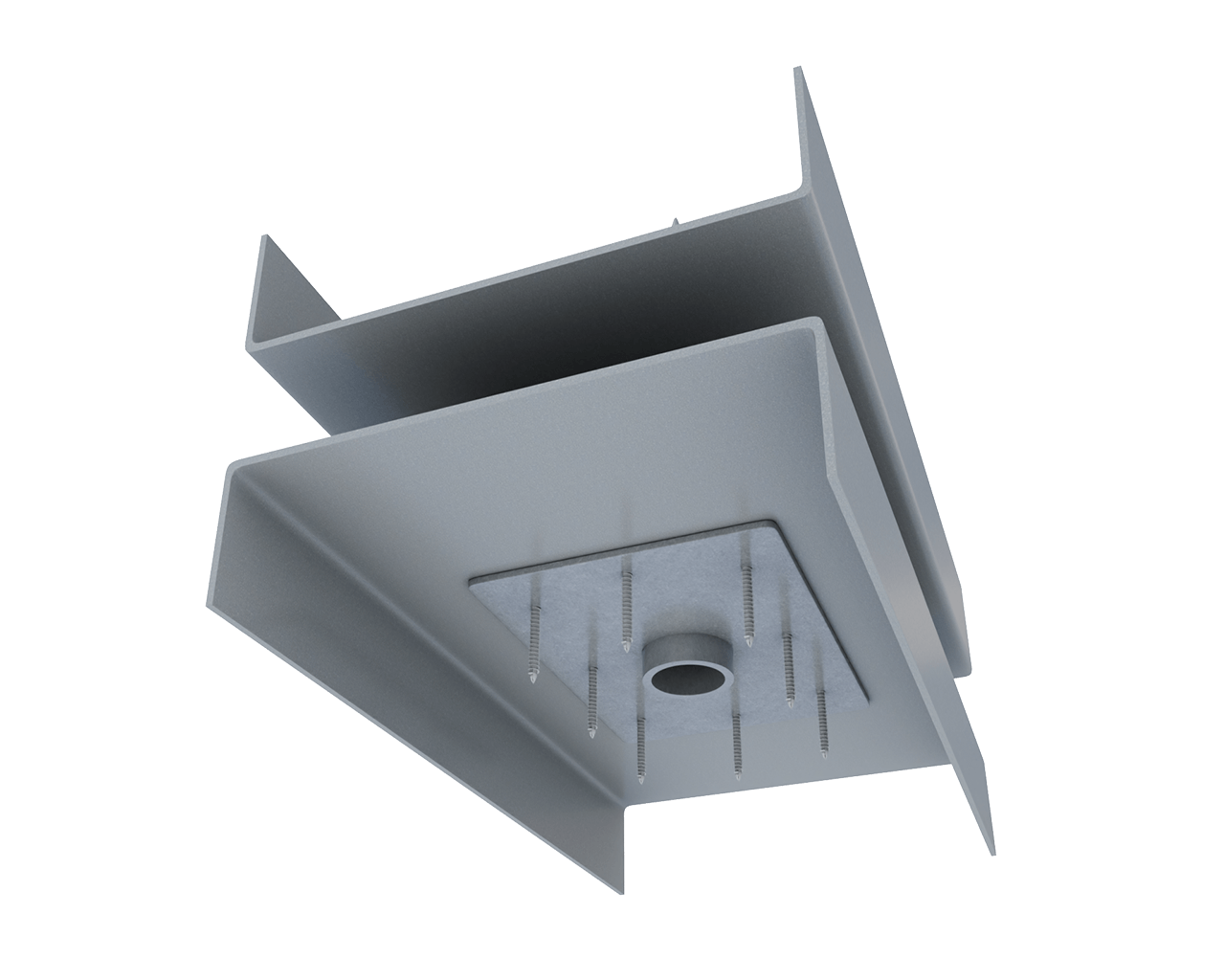

The attachment of a³LiGN™ plates to wall panel top and bottom tracks is made with (8) screw

anchors through a standard pre-punched hole pattern in the track sections.

a³LiGN™ Downloads

a³LiGN™ Applications

ARP or AOP with ABT – Full Assembly

ARP or AOP with APT – Full Assembly

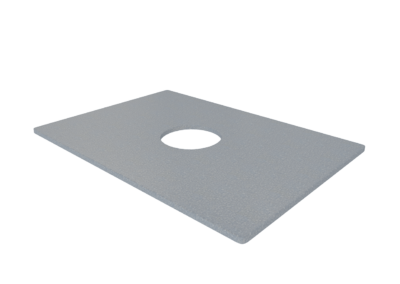

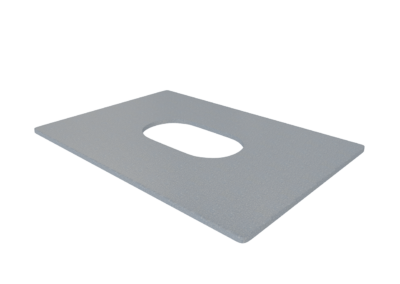

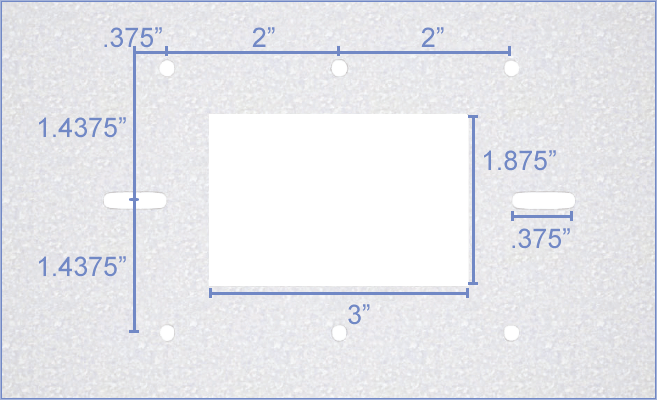

Typical Track Punch Pattern

a³LiGN™ alignment plates and assemblies are available slotted, round, and in two thicknesses: 97mil and 118mil. Alignment pins are welded to round hole plates and drift pins are removable guides for panel installation. An alignment base configuration is also available for direct attachment to structure.

Nomeclature

| Part # | Box Qty | Box Weight | Box / Pallet | Pallet QTY | Pallet Weight |

| Drift Pin – ADP | 5 | 5.4 | n/a | n/a | n/a |

| Oval Hole Plate – AOP10 | 50 | 37.9 | 40 | 2000 | 1551 |

| Oval Hole Plate – AOP12 | 50 | 31.4 | 40 | 2000 | 1291 |

| Round Hole Plate – ARP10 | 50 | 40.9 | 40 | 2000 | 1671 |

| Round Hole Plate – ARP12 | 50 | 33.4 | 40 | 2000 | 1371 |

| Plate Tube – APT10 | 25 | 37.0 | 48 | 1200 | 1813 |

| Plate Tube – APT12 | 35 | 47.4 | 40 | 1400 | 1929 |

| Base Tube – ABT | 25 | 22.3 | 45 | 1125 | 1039 |

a³LiGN™ Allowable Loads¹

Load Table Notes:

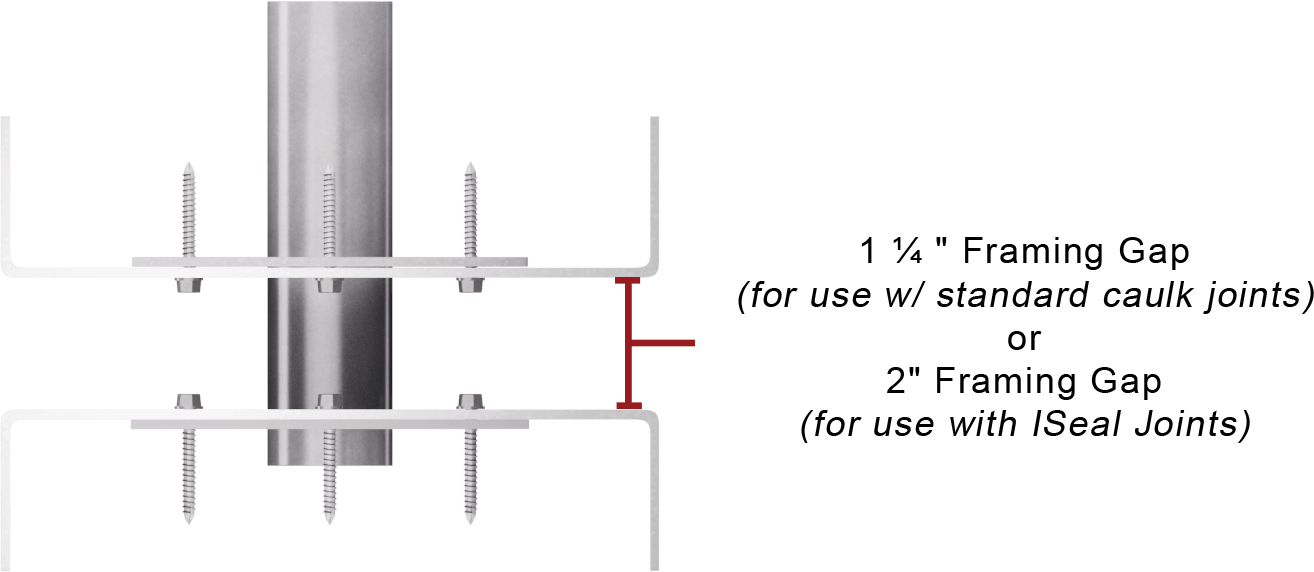

- Allowable loads are valid for alignment plate attachments to

tracks when using #12-14 SDS. - Screws are to be fastened through the top and bottom track

into the alignment plates, with the screw points pointing away

from the framing gap. - Framing gap is the gap between the top and bottom track,

considered as 1 ¼” (for standard caulk joints) or 2″ (for iSeal

Joints). - Alignment plates are assumed to be attached to the top and

bottom track with the ‘long’ dimension parallel to the run of

wall. - Allowable loads have not been increased for wind, seismic, or

other factors. - Slotted hole plates allow up to 1 ⅛” horizontal pin movement (9/16″ in each direction) to align panel framing.

- For LRFD Strengths contact TSN technical services at 888-474-4876

Follow us on Social Media