JamStud® Jams & Headers

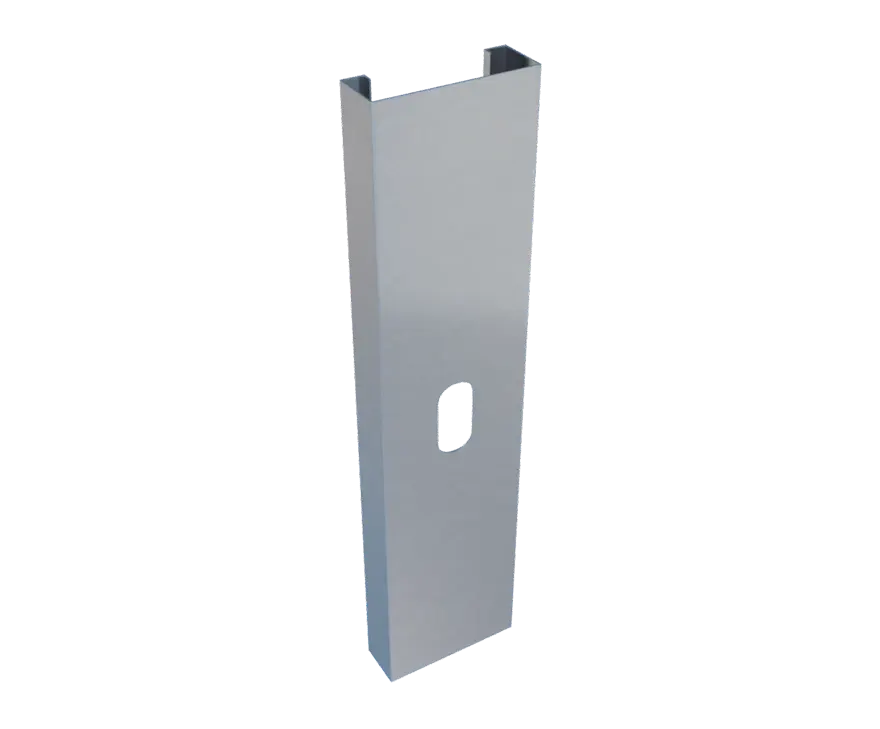

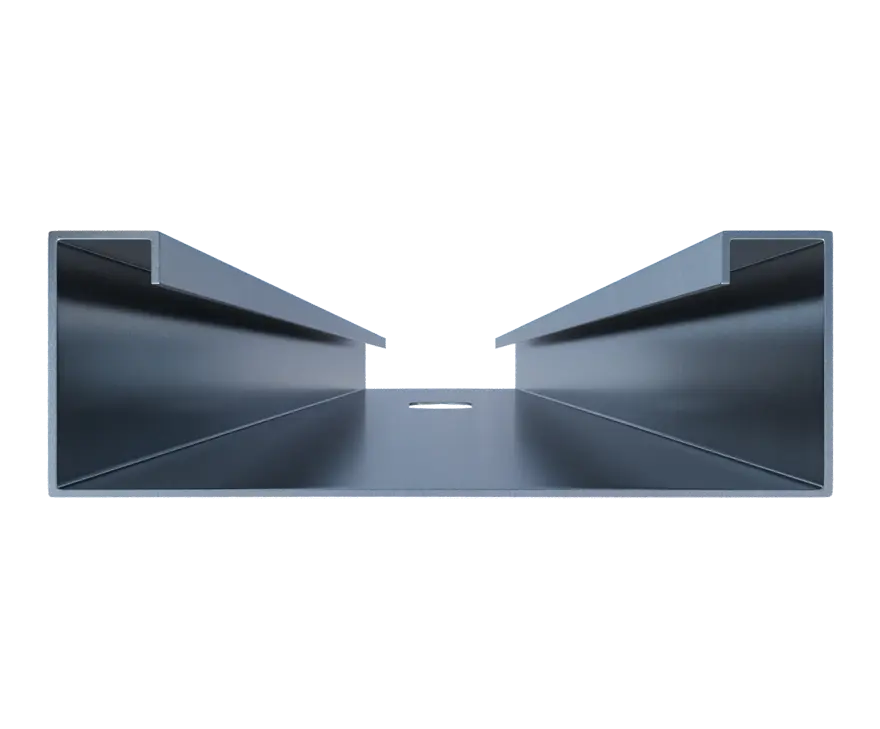

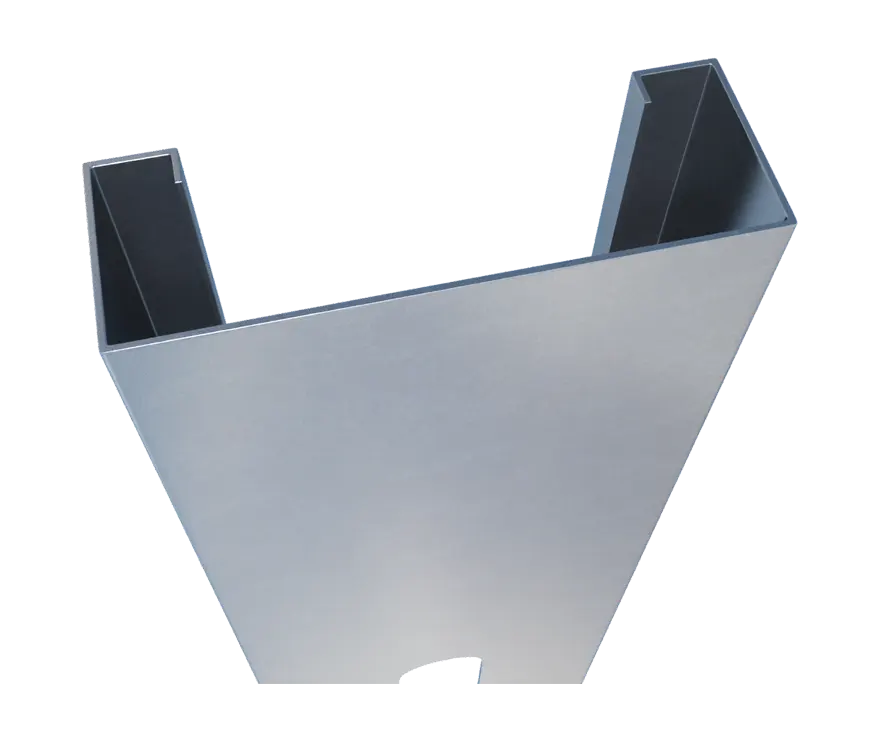

JamStud’s unique configuration delivers increased strength and stiffness versus standard “C” Shaped cold-formed steel studs. This allows for the reduction and/or elimination of built-up jamb and header sections in curtain wall and loadbearing wall assemblies.

Features

- Increases load capacity over a standard “C-shaped” stud of the same thickness

- Reduces overall materials used (single “JAM” from double or triple “C-Shape” common)

- Provides a flat surface for attachment of door or window frame (no additional track required)

- No welding or fastening built-up members together

- Lighter weight results in easier handling & shipping efficiencies

- Simplified jamb and header design

- Increased load capacity enables selection of optimal thickness of curtain wall studs

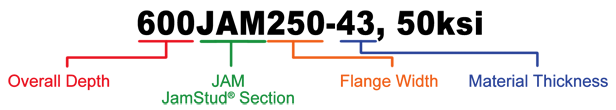

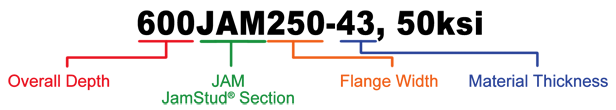

Nomenclature

Material Composition

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. JamStud® can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

JamStud Downloads

JamStud® Applications

Window Jams, Headers, & Sils

Installation Instructions

JamStud Design Information

|

|

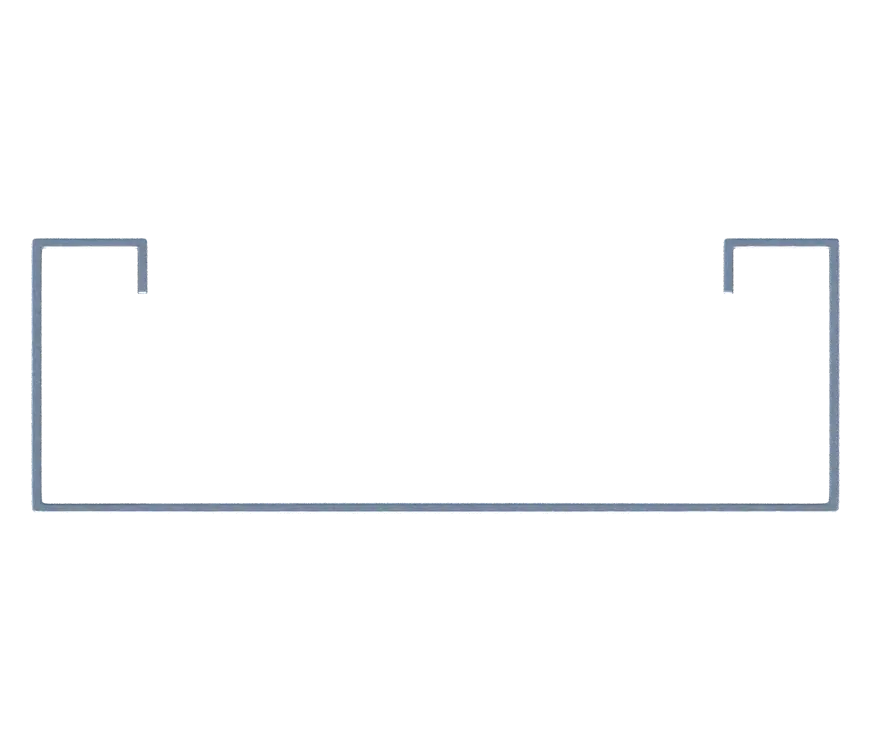

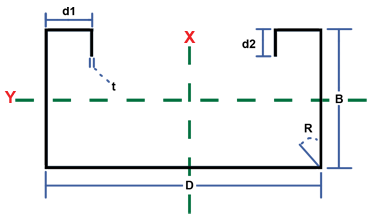

| JamStud® Product Profile | |||||||

| Section (All 50 ksi) |

Overall Depth | Flange Width | Return Lip 1 | Return Lip 2 | Inside Bend | Design Thickness | Unit Weight |

| D | B | d1 | d2 | R | t | (lbs/ft) | |

| (in) | (in) | (in) | (in) | (in) | (in) | ||

| 350JAM250-33 | 3.5 | 2.5 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.196 |

| 350JAM250-43 | 3.5 | 2.5 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.553 |

| 350JAM250-54 | 3.5 | 2.5 | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.942 |

| 350JAM250-68 | 3.5 | 2.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.435 |

| 350JAM250-97 | 3.5 | 2.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.438 |

| 350JAM350-68 | 3.5 | 3.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.920 |

| 362JAM250-33 | 3.625 | 2.5 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.210 |

| 362JAM250-43 | 3.625 | 2.5 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.572 |

| 362JAM250-54 | 3.625 | 2.5 | 0.6332 | 0.5 | 0.105 | 0.0566 | 1.966 |

| 362JAM250-68 | 3.625 | 2.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.465 |

| 362JAM250-97 | 3.625 | 2.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.481 |

| 362JAM350-68 | 3.625 | 3.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.950 |

| 400JAM250-33 | 4 | 2.5 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.255 |

| 400JAM250-43 | 4 | 2.5 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.630 |

| 400JAM250-54 | 4 | 2.5 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.038 |

| 400JAM250-68 | 4 | 2.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.556 |

| 400JAM250-97 | 4 | 2.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 3.611 |

| 400JAM350-68 | 4 | 3.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.041 |

| 400JAM350-97 | 4 | 3.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.303 |

| 400JAM350-118 | 4 | 3.5 | 0.7684 | 0.5 | 0.105 | 0.1242 | 5.216 |

| 550JAM250-33 | 5.5 | 2.5 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.431 |

| 550JAM250-43 | 5.5 | 2.5 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.860 |

| 550JAM250-54 | 5.5 | 2.5 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.327 |

| 550JAM250-68 | 5.5 | 2.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 2.920 |

| 550JAM250-97 | 5.5 | 2.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.130 |

| 550JAM250-118 | 5.5 | 2.5 | 0.7684 | 0.5 | 0.105 | 0.1242 | 5.005 |

| 550JAM350-68 | 5.5 | 3.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.405 |

| 550JAM350-97 | 5.5 | 3.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.822 |

| 550JAM350-118 | 5.5 | 3.5 | 0.7684 | 0.5 | 0.105 | 0.1242 | 5.849 |

| 600JAM250-33 | 6 | 2.5 | 0.5892 | 0.5 | 0.105 | 0.0346 | 1.490 |

| 600JAM250-43 | 6 | 2.5 | 0.6102 | 0.5 | 0.105 | 0.0451 | 1.937 |

| 600JAM250-54 | 6 | 2.5 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.424 |

| 600JAM250-68 | 6 | 2.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.041 |

| 600JAM250-97 | 6 | 2.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.303 |

| 600JAM250-118 | 6 | 2.5 | 0.7684 | 0.5 | 0.105 | 0.1242 | 5.216 |

| 600JAM350-68 | 6 | 3.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.527 |

| 600JAM350-97 | 6 | 3.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.995 |

| 600JAM350-118 | 6 | 3.5 | 0.7684 | 0.5 | 0.105 | 0.1242 | 6.060 |

| 800JAM250-43 | 8 | 2.5 | 0.6102 | 0.5 | 0.105 | 0.0451 | 2.244 |

| 800JAM250-54 | 8 | 2.5 | 0.6332 | 0.5 | 0.105 | 0.0566 | 2.809 |

| 800JAM250-68 | 8 | 2.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 3.527 |

| 800JAM250-97 | 8 | 2.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 4.995 |

| 800JAM250-118 | 8 | 2.5 | 0.7684 | 0.5 | 0.105 | 0.1242 | 6.060 |

| 800JAM350-68 | 8 | 3.5 | 0.6626 | 0.5 | 0.105 | 0.0713 | 4.012 |

| 800JAM350-97 | 8 | 3.5 | 0.7234 | 0.5 | 0.105 | 0.1017 | 5.688 |

| 800JAM350-118 | 8 | 3.5 | 0.7684 | 0.5 | 0.105 | 0.1242 | 6.904 |

Notes:

- Effective properties incorporate the strength increase from the cold-work of forming as applicable per AISI S100-16 Spec, Sec A3.3.2 (3).

- Tabulated gross properties are based on the full-unreduced cross section of the studs, away from punchouts.

- Allowable moment is the lesser of Mal and Mad. Stud distortional buckling is based on an assumed kΦ = 0.

- For deflection calculations, use the effective moment of inertia.

- The effective moment of inertia for deflection is calculated at a stress which results in a section modulus such that the stress times the section modulus at that stress is equal to the allowable moment. AISI S100-16 Spec Procedure I for serviceability determination has been used.

| JamStud® Section Properties: Gross Properties (for Un-punched Sections) | ||||||||||||

| Section (All 50 ksi) |

Area | Ix | Sx | Rx | Iy | Ry | Jx1000 | Cw | Ro | m | Xo | ß |

| (in2) | (in4) | (in3) | (in) | (in4) | (in) | (in4) | (in6) | (in) | (in) | (in) | ||

| 350JAM250-33 | 0.351 | 0.734 | 0.419 | 1.445 | 0.329 | 0.967 | 0.140 | 1.206 | 3.025 | 1.448 | -2.476 | 0.330 |

| 350JAM250-43 | 0.456 | 0.945 | 0.540 | 1.439 | 0.424 | 0.964 | 0.309 | 1.565 | 3.017 | 1.445 | -2.471 | 0.329 |

| 350JAM250-54 | 0.571 | 1.171 | 0.669 | 1.432 | 0.526 | 0.960 | 0.609 | 1.953 | 3.008 | 1.442 | -2.465 | 0.329 |

| 350JAM250-68 | 0.715 | 1.450 | 0.829 | 1.424 | 0.653 | 0.955 | 1.212 | 2.443 | 2.996 | 1.439 | -2.457 | 0.328 |

| 350JAM250-97 | 1.010 | 1.999 | 1.142 | 1.406 | 0.904 | 0.946 | 3.483 | 3.431 | 2.972 | 1.430 | -2.441 | 0.325 |

| 350JAM350-68 | 0.858 | 1.870 | 1.068 | 1.476 | 1.471 | 1.309 | 1.454 | 5.401 | 3.980 | 1.965 | -3.456 | 0.246 |

| 362JAM250-33 | 0.356 | 0.795 | 0.438 | 1.495 | 0.333 | 0.968 | 0.142 | 1.277 | 3.031 | 1.437 | -2.453 | 0.345 |

| 362JAM250-43 | 0.462 | 1.024 | 0.565 | 1.489 | 0.430 | 0.964 | 0.313 | 1.656 | 3.023 | 1.435 | -2.447 | 0.344 |

| 362JAM250-54 | 0.578 | 1.269 | 0.700 | 1.482 | 0.533 | 0.961 | 0.617 | 2.066 | 3.014 | 1.432 | -2.442 | 0.344 |

| 362JAM250-68 | 0.724 | 1.573 | 0.868 | 1.474 | 0.662 | 0.956 | 1.227 | 2.583 | 3.002 | 1.428 | -2.434 | 0.342 |

| 362JAM250-97 | 1.023 | 2.169 | 1.197 | 1.456 | 0.916 | 0.946 | 3.527 | 3.625 | 2.977 | 1.420 | -2.418 | 0.340 |

| 362JAM350-68 | 0.867 | 2.023 | 1.116 | 1.528 | 1.491 | 1.311 | 1.469 | 5.715 | 3.977 | 1.954 | -3.430 | 0.256 |

| 400JAM250-33 | 0.369 | 0.995 | 0.497 | 1.643 | 0.346 | 0.969 | 0.147 | 1.506 | 3.055 | 1.407 | -2.386 | 0.390 |

| 400JAM250-43 | 0.479 | 1.283 | 0.641 | 1.637 | 0.446 | 0.965 | 0.325 | 1.951 | 3.046 | 1.404 | -2.381 | 0.389 |

| 400JAM250-54 | 0.599 | 1.591 | 0.796 | 1.630 | 0.554 | 0.962 | 0.640 | 2.432 | 3.037 | 1.401 | -2.375 | 0.388 |

| 400JAM250-68 | 0.751 | 1.975 | 0.987 | 1.622 | 0.688 | 0.957 | 1.273 | 3.038 | 3.025 | 1.398 | -2.368 | 0.387 |

| 400JAM250-97 | 1.061 | 2.730 | 1.365 | 1.604 | 0.953 | 0.948 | 3.658 | 4.255 | 3.000 | 1.390 | -2.352 | 0.386 |

| 400JAM350-68 | 0.894 | 2.525 | 1.263 | 1.681 | 1.547 | 1.316 | 1.514 | 6.736 | 3.976 | 1.922 | -3.354 | 0.288 |

| 400JAM350-97 | 1.265 | 3.503 | 1.751 | 1.664 | 2.158 | 1.306 | 4.360 | 9.488 | 3.953 | 1.915 | -3.339 | 0.286 |

| 400JAM350-118 | 1.533 | 4.184 | 2.092 | 1.652 | 2.587 | 1.299 | 7.855 | 11.458 | 3.936 | 1.909 | -3.328 | 0.285 |

| 550JAM250-33 | 0.421 | 2.063 | 0.750 | 2.215 | 0.390 | 0.962 | 0.168 | 2.703 | 3.239 | 1.300 | -2.158 | 0.556 |

| 550JAM250-43 | 0.547 | 2.667 | 0.970 | 2.209 | 0.503 | 0.959 | 0.371 | 3.497 | 3.230 | 1.297 | -2.153 | 0.556 |

| 550JAM250-54 | 0.684 | 3.317 | 1.206 | 2.202 | 0.625 | 0.956 | 0.730 | 4.352 | 3.221 | 1.294 | -2.147 | 0.556 |

| 550JAM250-68 | 0.858 | 4.129 | 1.501 | 2.194 | 0.776 | 0.951 | 1.454 | 5.423 | 3.208 | 1.290 | -2.139 | 0.555 |

| 550JAM250-97 | 1.214 | 5.747 | 2.090 | 2.176 | 1.077 | 0.942 | 4.184 | 7.559 | 3.183 | 1.282 | -2.123 | 0.555 |

| 550JAM250-118 | 1.471 | 6.881 | 2.502 | 2.163 | 1.285 | 0.935 | 7.538 | 9.058 | 3.163 | 1.275 | -2.111 | 0.555 |

| 550JAM350-68 | 1.001 | 5.180 | 1.883 | 2.275 | 1.743 | 1.320 | 1.696 | 12.048 | 4.054 | 1.806 | -3.084 | 0.421 |

| 550JAM350-97 | 1.417 | 7.228 | 2.629 | 2.259 | 2.434 | 1.311 | 4.886 | 16.898 | 4.029 | 1.798 | -3.069 | 0.420 |

| 550JAM350-118 | 1.719 | 8.673 | 3.154 | 2.246 | 2.921 | 1.304 | 8.809 | 20.344 | 4.012 | 1.792 | -3.057 | 0.419 |

| 600JAM250-33 | 0.438 | 2.522 | 0.841 | 2.400 | 0.402 | 0.958 | 0.175 | 3.209 | 3.326 | 1.269 | -2.094 | 0.604 |

| 600JAM250-43 | 0.569 | 3.261 | 1.087 | 2.394 | 0.519 | 0.955 | 0.386 | 4.150 | 3.317 | 1.266 | -2.088 | 0.604 |

| 600JAM250-54 | 0.712 | 4.058 | 1.353 | 2.387 | 0.644 | 0.951 | 0.760 | 5.163 | 3.307 | 1.263 | -2.082 | 0.604 |

| 600JAM250-68 | 0.894 | 5.055 | 1.685 | 2.378 | 0.801 | 0.947 | 1.514 | 6.431 | 3.295 | 1.259 | -2.074 | 0.604 |

| 600JAM250-97 | 1.265 | 7.047 | 2.349 | 2.361 | 1.111 | 0.937 | 4.360 | 8.956 | 3.269 | 1.250 | -2.058 | 0.604 |

| 600JAM250-118 | 1.533 | 8.447 | 2.816 | 2.348 | 1.327 | 0.930 | 7.855 | 10.726 | 3.250 | 1.244 | -2.045 | 0.604 |

| 600JAM350-68 | 1.036 | 6.309 | 2.103 | 2.467 | 1.799 | 1.318 | 1.756 | 14.285 | 4.106 | 1.771 | -3.006 | 0.464 |

| 600JAM350-97 | 1.468 | 8.816 | 2.939 | 2.451 | 2.513 | 1.308 | 5.061 | 20.020 | 4.081 | 1.763 | -2.990 | 0.463 |

| 600JAM350-118 | 1.781 | 10.588 | 3.529 | 2.438 | 3.017 | 1.302 | 9.127 | 24.090 | 4.063 | 1.757 | -2.978 | 0.463 |

| 800JAM250-43 | 0.659 | 6.378 | 1.595 | 3.110 | 0.572 | 0.931 | 0.447 | 7.513 | 3.746 | 1.159 | -1.869 | 0.751 |

| 800JAM250-54 | 0.825 | 7.949 | 1.987 | 3.103 | 0.710 | 0.927 | 0.881 | 9.340 | 3.736 | 1.156 | -1.862 | 0.752 |

| 800JAM250-68 | 1.036 | 9.923 | 2.481 | 3.095 | 0.883 | 0.923 | 1.756 | 11.624 | 3.724 | 1.151 | -1.854 | 0.752 |

| 800JAM250-97 | 1.468 | 13.893 | 3.473 | 3.076 | 1.225 | 0.914 | 5.061 | 16.161 | 3.698 | 1.142 | -1.838 | 0.753 |

| 800JAM250-118 | 1.781 | 16.707 | 4.177 | 3.063 | 1.464 | 0.907 | 9.127 | 19.330 | 3.679 | 1.136 | -1.825 | 0.754 |

| 800JAM350-68 | 1.179 | 12.165 | 3.041 | 3.212 | 1.990 | 1.299 | 1.998 | 25.787 | 4.413 | 1.648 | -2.733 | 0.616 |

| 800JAM350-97 | 1.671 | 17.065 | 4.266 | 3.195 | 2.782 | 1.290 | 5.762 | 36.082 | 4.388 | 1.640 | -2.717 | 0.617 |

| 800JAM350-118 | 2.029 | 20.553 | 5.138 | 3.183 | 3.341 | 1.283 | 10.398 | 43.367 | 4.370 | 1.633 | -2.705 | 0.617 |

Notes:

- Effective properties incorporate the strength increase from the cold-work of forming as applicable per AISI S100-16 Spec, Sec. A3.3.2 (3).

- Tabulated gross properties are based on the full-unreduced cross section of the studs, away from punchouts.

- Allowable moment is the lesser of Mal and Mad. Stud distortional buckling is based on an assumed kΦ = 0.

- For deflection calculations, use the effective moment of inertia.

- The effective moment of inertia for deflection is calculated at a stress which results in a section modulus such that the stress times the section modulus at that stress is equal to the allowable moment. AISI S100-16 Procedure I for Serviceability Determination has been used.

| JamStud® Section Properties | |||||||||||||||||||

| Section (All 50 ksi) |

Effective Properties 50 ksi (“net” = Punched Sections) | Effective Properties if limited to 33 ksi Strength | |||||||||||||||||

| Ixe | Sxe | Sxe (net) | Mal | Mal (net) | Mad | Mad (net) | Va | Va (net) | Iye1 | Myal1 | Myad1 | Iye2 | Myal2 | Ixe | Mal | Mal (net) | Mad | Mad (net) | |

| (in4) | (in3) | (in3) | (in-k) | (in-k) | (in-k) | (in-k) | (lb) | (lb) | (in4) | (in-k) | (in-k) | (in4) | (in-k) | (in4) | (in-k) | (in-k) | (in-k) | (in-k) | |

| 350JAM250-33 | 0.693 | 0.331 | 0.300 | 9.904 | 8.995 | 9.106 | 8.870 | 1,144 | 527 | 0.329 | 6.761 | 6.643 | 0.273 | 5.897 | 0.714 | 7.010 | 6.548 | 6.973 | 6.809 |

| 350JAM250-43 | 0.933 | 0.447 | 0.418 | 13.371 | 12.505 | 13.045 | 12.687 | 2,141 | 747 | 0.424 | 8.738 | 8.738 | 0.383 | 8.097 | 0.945 | 9.764 | 9.389 | 9.864 | 9.628 |

| 350JAM250-54 | 1.171 | 0.571 | 0.545 | 17.099 | 16.324 | 17.616 | 17.120 | 3,371 | 925 | 0.526 | 10.864 | 10.864 | 0.508 | 10.390 | 1.171 | 12.370 | 12.069 | 13.136 | 12.804 |

| 350JAM250-68 | 1.450 | 0.748 | 0.728 | 22.400 | 21.809 | 23.676 | 23.014 | 4,208 | 900 | 0.653 | 13.522 | 13.522 | 0.653 | 13.302 | 1.450 | 17.765 | 17.494 | 18.039 | 17.735 |

| 350JAM250-97 | 1.999 | 1.125 | 1.107 | 37.597 | 37.006 | 38.177 | 37.438 | 5,886 | 850 | 0.904 | 18.806 | 18.806 | 0.904 | 18.806 | 1.999 | 25.603 | 25.240 | 25.603 | 25.237 |

| 350JAM350-68 | 1.812 | 0.804 | 0.774 | 24.073 | 23.179 | 26.651 | 25.932 | 4,208 | 900 | 1.471 | 22.321 | 22.321 | 1.471 | 21.873 | 1.866 | 17.681 | 17.250 | 20.057 | 19.595 |

| 362JAM250-33 | 0.751 | 0.347 | 0.313 | 10.387 | 9.375 | 9.461 | 9.217 | 1,102 | 544 | 0.333 | 6.795 | 6.573 | 0.273 | 5.910 | 0.774 | 7.345 | 6.827 | 7.249 | 7.080 |

| 362JAM250-43 | 1.011 | 0.468 | 0.435 | 14.012 | 13.038 | 13.565 | 13.194 | 2,141 | 802 | 0.430 | 8.783 | 8.783 | 0.384 | 8.106 | 1.024 | 10.223 | 9.796 | 10.265 | 10.021 |

| 362JAM250-54 | 1.269 | 0.598 | 0.569 | 17.908 | 17.031 | 18.335 | 17.821 | 3,372 | 994 | 0.533 | 10.921 | 10.921 | 0.511 | 10.406 | 1.269 | 12.944 | 12.598 | 13.687 | 13.369 |

| 362JAM250-68 | 1.573 | 0.783 | 0.761 | 23.449 | 22.775 | 24.670 | 23.982 | 4,375 | 1,007 | 0.662 | 13.593 | 13.593 | 0.662 | 13.332 | 1.573 | 18.596 | 18.333 | 18.889 | 18.574 |

| 362JAM250-97 | 2.169 | 1.178 | 1.161 | 39.389 | 38.814 | 40.011 | 39.252 | 6,124 | 954 | 0.916 | 18.908 | 18.908 | 0.916 | 18.908 | 2.169 | 26.833 | 26.483 | 26.833 | 26.480 |

| 362JAM350-68 | 1.961 | 0.841 | 0.808 | 25.186 | 24.190 | 27.689 | 26.946 | 4,375 | 1,007 | 1.491 | 22.444 | 22.444 | 1.491 | 21.921 | 2.019 | 18.481 | 18.050 | 20.857 | 20.377 |

| 400JAM250-33 | 0.944 | 0.397 | 0.351 | 11.873 | 10.514 | 10.530 | 10.264 | 991 | 589 | 0.346 | 6.891 | 6.331 | 0.275 | 5.944 | 0.971 | 8.375 | 7.661 | 8.083 | 7.897 |

| 400JAM250-43 | 1.268 | 0.534 | 0.489 | 15.981 | 14.635 | 15.133 | 14.726 | 2,141 | 967 | 0.446 | 8.908 | 8.908 | 0.389 | 8.130 | 1.283 | 11.631 | 11.014 | 11.479 | 11.208 |

| 400JAM250-54 | 1.591 | 0.681 | 0.640 | 20.397 | 19.150 | 20.506 | 19.938 | 3,372 | 1,201 | 0.554 | 11.077 | 11.077 | 0.520 | 10.449 | 1.591 | 14.708 | 14.190 | 15.351 | 14.995 |

| 400JAM250-68 | 1.975 | 0.891 | 0.858 | 26.669 | 25.675 | 27.679 | 26.913 | 4,876 | 1,360 | 0.688 | 13.790 | 13.790 | 0.686 | 13.411 | 1.975 | 21.143 | 19.215 | 21.490 | 19.313 |

| 400JAM250-97 | 2.730 | 1.343 | 1.351 | 44.884 | 40.448 | 45.635 | 40.443 | 6,839 | 1,299 | 0.953 | 19.189 | 19.189 | 0.953 | 19.189 | 2.730 | 30.605 | 30.288 | 30.605 | 30.284 |

| 400JAM350-68 | 2.447 | 0.955 | 0.909 | 28.602 | 27.223 | 30.818 | 30.002 | 4,876 | 1,360 | 1.547 | 22.789 | 22.789 | 1.530 | 22.043 | 2.519 | 20.930 | 20.378 | 23.268 | 22.736 |

| 400JAM350-97 | 3.483 | 1.502 | 1.473 | 44.961 | 44.092 | 49.104 | 47.809 | 6,839 | 1,299 | 2.158 | 31.903 | 31.903 | 2.158 | 31.903 | 3.503 | 36.019 | 35.587 | 37.965 | 37.478 |

| 400JAM350-118 | 4.184 | 1.980 | 1.955 | 59.268 | 58.533 | 62.640 | 61.275 | 8,235 | 1,256 | 2.587 | 38.361 | 38.361 | 2.587 | 38.361 | 4.184 | 44.732 | 44.265 | 46.055 | 45.671 |

| 550JAM250-33 | 1.978 | 0.572 | 0.572 | 17.118 | 17.118 | 14.859 | 14.508 | 706 | 703 | 0.390 | 7.183 | 5.159 | 0.280 | 6.030 | 2.022 | 12.848 | 12.848 | 11.473 | 11.223 |

| 550JAM250-43 | 2.650 | 0.820 | 0.820 | 24.561 | 24.561 | 21.511 | 20.968 | 1,570 | 1,192 | 0.503 | 9.288 | 7.645 | 0.400 | 8.190 | 2.667 | 17.716 | 17.716 | 16.435 | 16.062 |

| 550JAM250-54 | 3.317 | 1.043 | 1.043 | 31.227 | 31.227 | 29.377 | 28.604 | 3,117 | 1,875 | 0.625 | 11.554 | 10.621 | 0.542 | 10.559 | 3.317 | 22.334 | 22.334 | 22.187 | 21.682 |

| 550JAM250-68 | 4.129 | 1.357 | 1.357 | 40.642 | 40.642 | 40.041 | 38.971 | 5,352 | 2,535 | 0.776 | 14.391 | 14.391 | 0.728 | 13.608 | 4.129 | 32.111 | 32.111 | 31.984 | 31.245 |

| 550JAM250-97 | 5.747 | 2.051 | 2.051 | 68.578 | 68.578 | 68.487 | 66.650 | 9,700 | 3,167 | 1.077 | 20.045 | 20.045 | 1.077 | 19.791 | 5.747 | 46.849 | 46.849 | 46.849 | 46.616 |

| 550JAM250-118 | 6.881 | 2.502 | 2.502 | 85.210 | 85.210 | 85.210 | 84.778 | 11,723 | 3,100 | 1.285 | 24.010 | 24.010 | 1.285 | 24.010 | 6.881 | 57.274 | 57.274 | 57.274 | 56.984 |

| 550JAM350-68 | 4.957 | 1.450 | 1.450 | 43.421 | 43.421 | 43.539 | 42.448 | 5,352 | 2,535 | 1.743 | 23.876 | 23.876 | 1.613 | 22.354 | 5.144 | 31.469 | 31.469 | 33.109 | 32.375 |

| 550JAM350-97 | 7.160 | 2.262 | 2.262 | 67.718 | 67.718 | 70.434 | 68.637 | 9,700 | 3,167 | 2.434 | 33.453 | 33.453 | 2.434 | 32.810 | 7.228 | 53.935 | 53.935 | 56.053 | 54.824 |

| 550JAM350-118 | 8.673 | 2.976 | 2.976 | 89.112 | 89.112 | 91.138 | 88.891 | 11,723 | 3,100 | 2.921 | 40.250 | 40.250 | 2.921 | 40.250 | 8.673 | 67.271 | 67.271 | 69.422 | 69.143 |

| 600JAM250-33 | 2.424 | 0.626 | 0.626 | 18.750 | 18.750 | 16.312 | 15.936 | 644 | 644 | 0.402 | 7.257 | 4.783 | 0.281 | 6.049 | 2.477 | 14.179 | 14.179 | 12.615 | 12.346 |

| 600JAM250-43 | 3.245 | 0.919 | 0.919 | 27.502 | 27.502 | 23.662 | 23.076 | 1,432 | 1,235 | 0.519 | 9.385 | 7.166 | 0.403 | 8.203 | 3.261 | 19.902 | 19.902 | 18.114 | 17.709 |

| 600JAM250-54 | 4.058 | 1.174 | 1.174 | 35.140 | 35.140 | 32.383 | 31.545 | 2,842 | 1,942 | 0.644 | 11.676 | 10.070 | 0.546 | 10.582 | 4.058 | 25.073 | 25.073 | 24.516 | 23.962 |

| 600JAM250-68 | 5.055 | 1.526 | 1.526 | 45.679 | 45.679 | 44.254 | 43.085 | 5,352 | 2,882 | 0.801 | 14.544 | 14.059 | 0.737 | 13.650 | 5.055 | 36.037 | 36.037 | 35.425 | 34.610 |

| 600JAM250-97 | 7.047 | 2.305 | 2.305 | 77.070 | 77.070 | 76.026 | 73.996 | 10,653 | 3,964 | 1.111 | 20.261 | 20.261 | 1.111 | 19.891 | 7.047 | 52.663 | 52.663 | 52.663 | 52.449 |

| 600JAM250-118 | 8.447 | 2.816 | 2.816 | 95.893 | 95.893 | 95.893 | 95.389 | 12,885 | 3,889 | 1.327 | 24.274 | 24.274 | 1.327 | 24.264 | 8.447 | 64.455 | 64.455 | 64.455 | 64.189 |

| 600JAM350-68 | 6.055 | 1.628 | 1.628 | 48.757 | 48.757 | 47.851 | 46.671 | 5,352 | 2,882 | 1.799 | 24.160 | 23.707 | 1.631 | 22.421 | 6.263 | 35.238 | 35.238 | 36.455 | 35.655 |

| 600JAM350-97 | 8.730 | 2.534 | 2.534 | 75.856 | 75.856 | 77.711 | 75.750 | 10,653 | 3,964 | 2.513 | 33.858 | 33.858 | 2.512 | 32.975 | 8.816 | 60.297 | 60.297 | 61.964 | 60.610 |

| 600JAM350-118 | 10.588 | 3.331 | 3.331 | 99.720 | 99.720 | 100.837 | 98.366 | 12,885 | 3,889 | 3.017 | 40.744 | 40.744 | 3.017 | 40.527 | 10.588 | 75.265 | 75.265 | 77.692 | 77.436 |

| 800JAM250-43 | 6.378 | 1.225 | 1.225 | 36.664 | 36.664 | 32.254 | 31.517 | 1,060 | 1,060 | 0.572 | 9.679 | 5.562 | 0.409 | 8.238 | 6.378 | 29.006 | 29.006 | 24.861 | 24.339 |

| 800JAM250-54 | 7.949 | 1.700 | 1.700 | 50.893 | 50.893 | 44.463 | 43.391 | 2,102 | 2,102 | 0.710 | 12.044 | 8.089 | 0.560 | 10.645 | 7.949 | 36.991 | 36.991 | 33.939 | 33.207 |

| 800JAM250-68 | 9.923 | 2.260 | 2.260 | 67.676 | 67.676 | 61.309 | 59.780 | 4,218 | 3,367 | 0.883 | 15.007 | 11.756 | 0.763 | 13.763 | 9.923 | 53.065 | 53.065 | 49.444 | 48.338 |

| 800JAM250-97 | 13.893 | 3.409 | 3.409 | 113.945 | 113.945 | 106.907 | 104.140 | 10,888 | 6,034 | 1.225 | 20.919 | 20.245 | 1.187 | 20.155 | 13.893 | 77.866 | 77.866 | 77.866 | 77.706 |

| 800JAM250-118 | 16.707 | 4.177 | 4.177 | 142.242 | 142.242 | 140.356 | 136.857 | 16,187 | 7,303 | 1.464 | 25.073 | 25.073 | 1.464 | 24.681 | 16.707 | 95.609 | 95.609 | 95.609 | 95.410 |

| 800JAM350-68 | 11.805 | 2.406 | 2.406 | 72.028 | 72.028 | 65.370 | 63.855 | 4,218 | 3,367 | 1.990 | 25.049 | 19.995 | 1.681 | 22.600 | 12.120 | 51.562 | 51.562 | 50.106 | 49.055 |

| 800JAM350-97 | 16.974 | 3.711 | 3.711 | 111.105 | 111.105 | 107.517 | 104.925 | 10,888 | 6,034 | 2.782 | 35.121 | 34.452 | 2.645 | 33.415 | 17.065 | 87.651 | 87.651 | 86.268 | 84.422 |

| 800JAM350-118 | 20.553 | 4.855 | 4.855 | 145.369 | 145.369 | 140.775 | 137.426 | 16,187 | 7,303 | 3.341 | 42.281 | 42.281 | 3.337 | 41.240 | 20.553 | 109.593 | 109.593 | 112.929 | 110.637 |

1 Iye, Myal, and Myad are based on the web element in tension

2 Iye, Myal, and Myad are based on the web element in compression

Notes:

- Effective properties incorporate the strength increase from the cold-work of forming as applicable per AISI S100-16 Spec, Sec. A3.3.2 (3).

- Tabulated gross properties are based on the full-unreduced cross section of the studs, away from punchouts.

- Allowable moment is the lesser of Mal and Mad. Stud distortional buckling is based on an assumed kΦ = 0.

- For deflection calculations, use the effective moment of inertia.

- The effective moment of inertia for deflection is calculated at a stress which results in a section modulus such that the stress times the section modulus at that stress is equal to the allowable moment. AISI S100-16 Procedure I for Serviceability Determination has been used.

1. Basis for Tables:

The JamStud® allowable heights tables on this site cover the following basic load combination for strength determination using the Allowable Stress Design (ASD) Method (IBC 2009/2012 and ASCE 7-05/10):

- D + WC&C (ASCE 7-05)

- D + 0.6WC&C (ASCE 7-10)

WC&C is the component & cladding wind load. The Dead Load (D) acting on the stud is assumed minimum and therefore neglected in the tables.

For deflection determination IBC 2009 and IBC 2012-Sec. 1604.3 and AISI-S211-07 Wall Stud Design Standard Sec. A3.1 allow for a reduction factor of 0.7 on the component & cladding wind load (0.7WC&C).

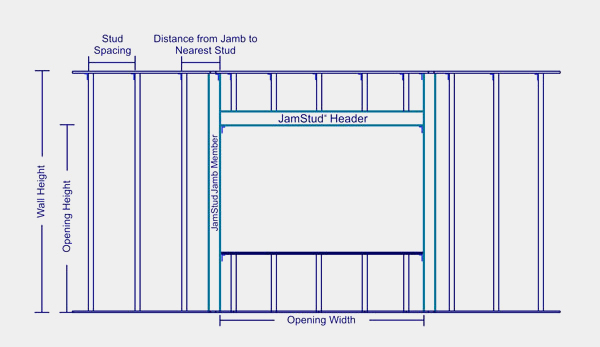

The “JamStud® – Allowable Heights” tables are based on the following assumptions:

- 4-Way distribution of lateral wind pressure acting on the opening

- Opening height extends from floor level to the bottom surface of the header

- Jamb member supports wind pressure from opening, wind pressure from half distance to adjacent stud, and header reaction

The input for the tables include: the JamStud section, the opening width (ft.), the opening height (ft.), the design wind pressure (WC&C, psf), and the specified deflection limit. The output from the tables reflects the allowable JamStud height (ft.-in.) and the controlling design factor, whether it is strength or deflection (“f” denotes strength, “d” denotes deflection). An “*” denotes critical web crippling at support of jamb. The use of stiffening clips at supports typically eliminates the web crippling condition.

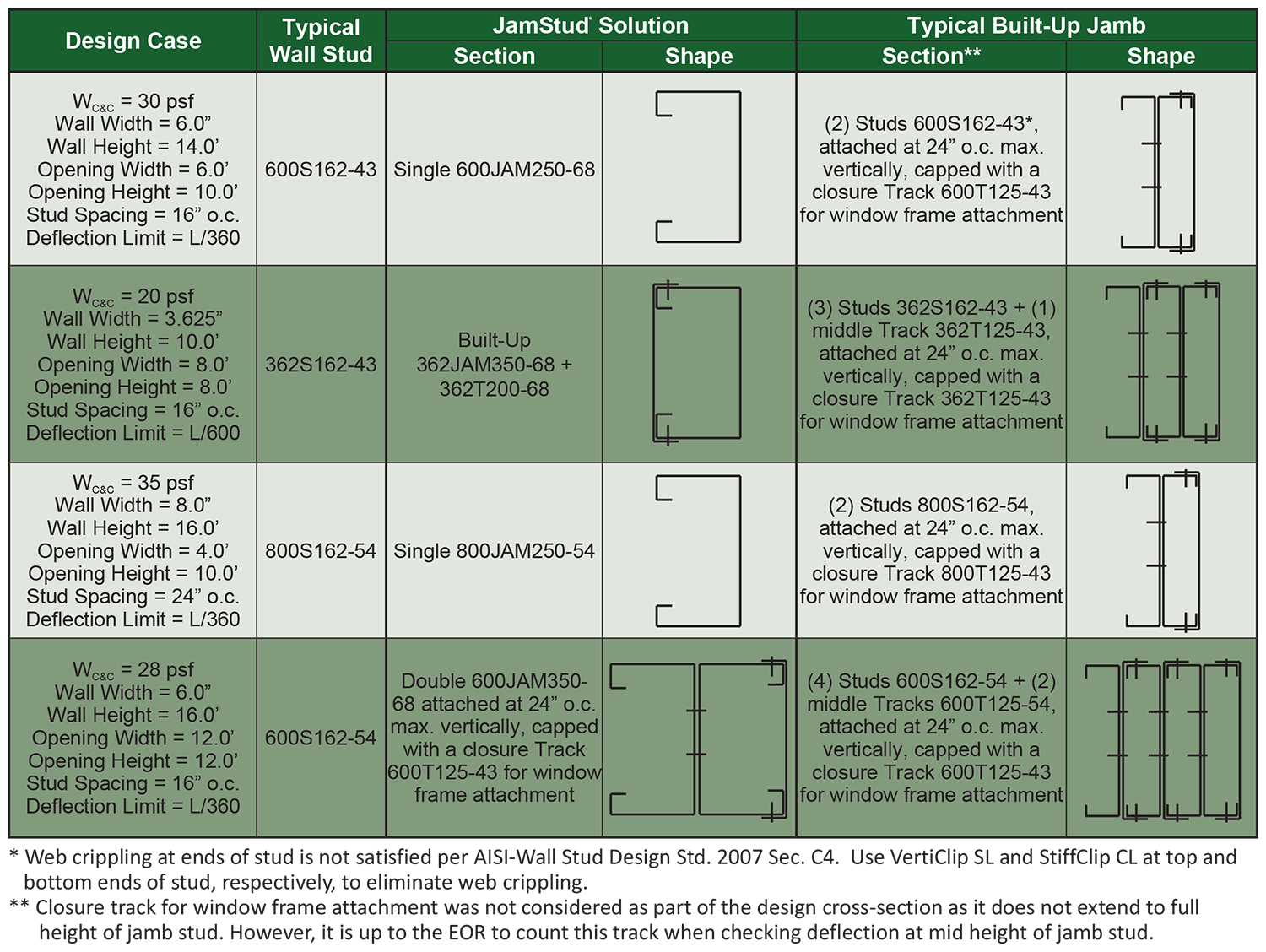

2. Design Example:

Given:

Wind Pressure (WC&C)(ASCE 7-05)

or (0.6WC&C)(ASCE 7-10) = 30 psf

Wall Width = 6.0 in.

Wall Height = 14.0 ft.

Opening Width = 8.0 ft.

Opening Height = 10.0 ft.

Stud Spacing = 16 in. o.c.

Specified Deflection Limit = L/360

Typical Stud 600S162-43

Bridging (Lateral Bracing) is recommended at a vertical spacing of 60” o.c. with both JamStud flanges connected to the sheathing.

Design Jamb:

Go to the “JamStud – Allowable Heights” table with 6” stud member, 30 psf wind load, L/360 deflection limit, 8.0 ft. opening width, and 10.0 ft. opening height. Possible JamStud selections from table for 14.0 ft. height are 600JAM250-97 (allowable height = 15’ 0”) and 600JAM350-68 (allowable height = 14’ 6”). The alternative with typical 43mil “cee” studs result in a built-up section comprised of (3) 600S162-43 capped by (2) 600T162-43.

Conclusion:

The second option, 600JAM350-68, is a lighter section with a lesser thickness. Use 600JAM350-68 (50ksi) (with design thickness = 0.0713” and Fy = 50 ksi). Allow 2 rows of bridging for the wall (including jamb stud) arranged so that the maximum spacing does not exceed 60 in. (5 ft.).

3. Extra Design Considerations:

Strength determination in the “JamStud – Allowable Heights” tables includes checks for bending and shear capacity values of the stud and a check for lateral end reaction of the stud for web crippling. If tables indicate critical web crippling (denoted with an “*”), you may use a clip at the top and bottom ends of stud to eliminate the web crippling condition.

Follow us on Social Media