StiffClip® TD

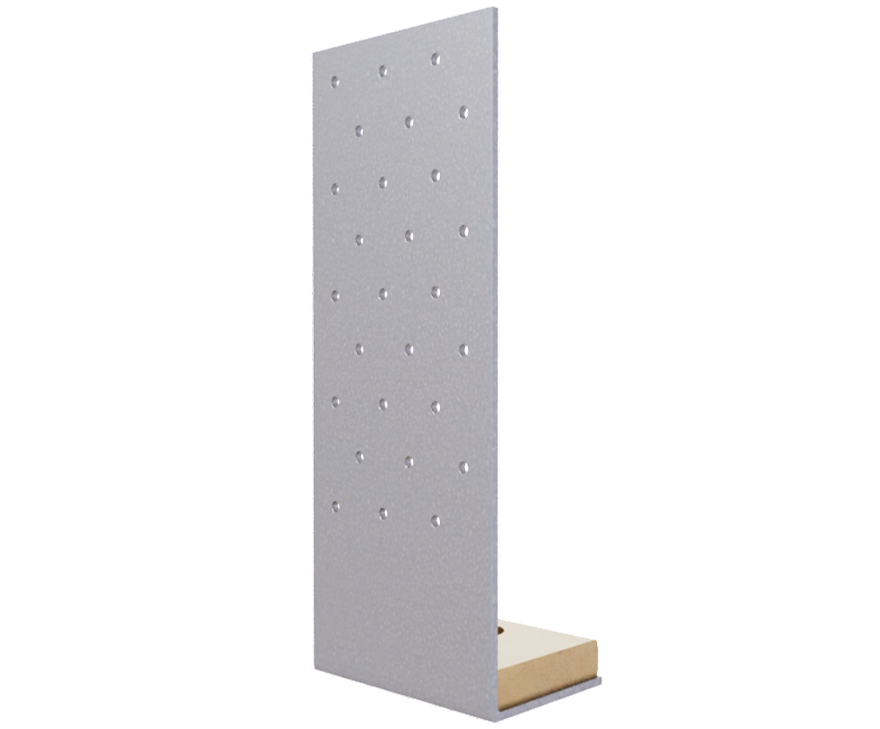

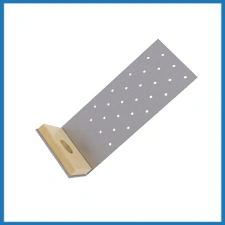

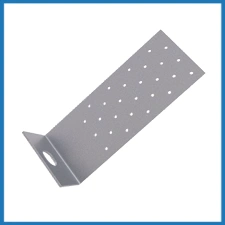

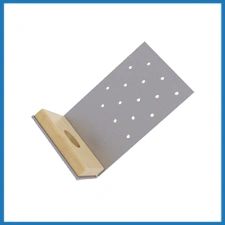

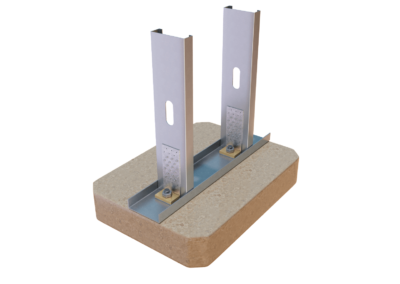

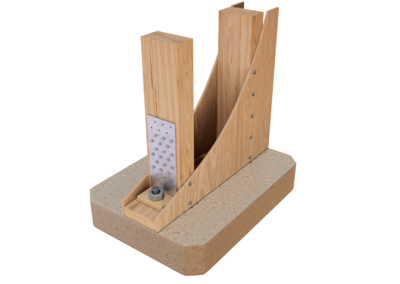

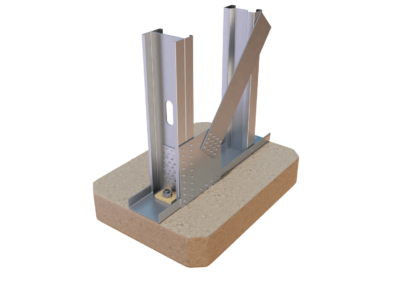

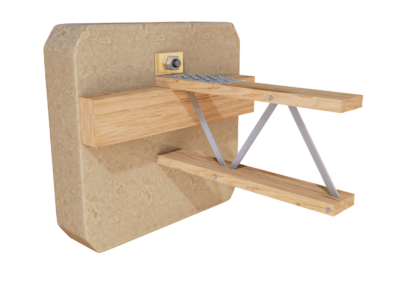

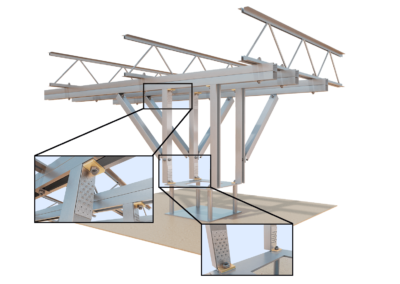

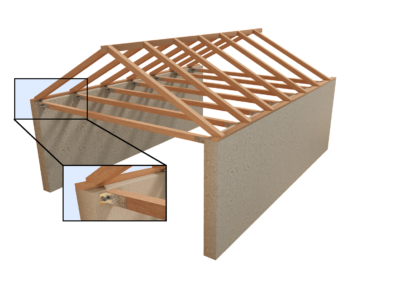

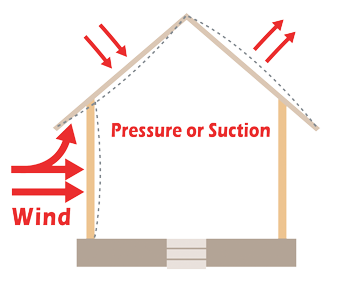

StiffClip® TD is engineered for optimal anchoring of wood or steel studs to the foundation. Available with or without a ¾” steel stiffening plate, StiffClip® TD is designed to resist vertical uplift loads, making it an ideal solution for wall stud tie-downs and anchorage in conventional strap/gusset-plate shear wall construction. Whether you’re working on a wood-framed residential project or a steel-framed commercial structure, StiffClip® TD offers the strength and adaptability needed to meet the demands of modern construction.

Features

- Guide holes for connections to stud and deck

- Stiffening plate for additional strength

- Clip utilizes certified, 50ksi or 55ksi steel

- Reduces material (replaces heavy steel angles)

- Extensively tested

Material Composition

TD-LT: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 118mil minimum thickness (10 gauge, 0.1242″ design thickness) with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating.

TD: ASTM A1003/A1003M Structural Grade 55 (380) Type H, ST55H (ST380H): 55ksi (380MPa) minimum yield strength, 70ksi (480MPa) minimum tensile strength, 118mil minimum thickness (10 gauge, 0.1242″ design thickness) with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating.

TD Plate: ASTM A36/A36M: 36ksi (250MPa) minimum yield strength, 58-80ksi (400-550MPa) minimum tensile strength, with ASTM B633 Type II Yellow Zinc Coating, Paint, Powder Coating, or E-Coating, or approved equivalent.

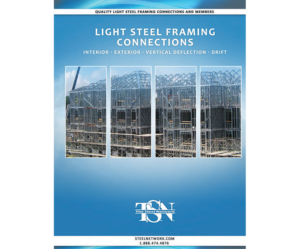

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. StiffClip® TD can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

Order Information

Nomeclature

StiffClip TD-LT is available in one size without the use of the ‘TD Plate’. Contact TSN about installation with alternate anchor sizes.

StiffClip TD is available in one size and can be used with or without a 3/4″ plate on top of the 2-3/8″ leg. Anchor hole accommodates 7/8″ diameter anchor.

Example: 6″ stud, 5/8″ dia. anchor to concrete, holddown without plate

Designate: StiffClip® TD-LT

Example: 8″ stud, 7/8″ dia. anchor to concrete, holddown with plate

Designate: StiffClip® TD w/ Plate

Superior Strength for Your Projects

The StiffClip TD is engineered to provide unmatched strength and reliability in light steel framing applications. Designed to resist vertical uplift forces, it’s the ideal solution for securing wood or steel studs to foundations or as an anchorage component in shear wall construction.

Watch the Video

See StiffClip TD in action! This short video demonstrates its ease of installation, durability, and the innovative features that make it a trusted choice for contractors and engineers alike. From its high-strength 50ksi steel construction to pre-punched guide holes for precise placement, StiffClip TD is built to deliver results that last.

StiffClip® TD Downloads

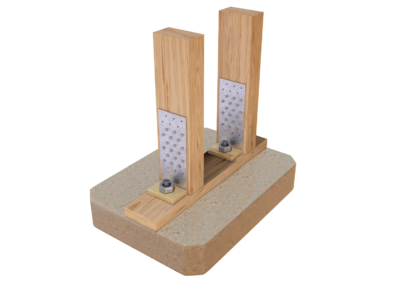

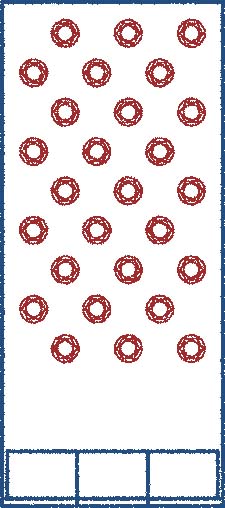

StiffClip® TD Applications

Installation Instructions

- Place StiffClip TD at bottom of stud and attach clip to deck with approved anchor.

- For StiffClip TD w/ Plate, insert the plate over anchor as specified.

- Attach StiffClip TD to the structure with specified anchors. Refer to Design Drawings for anchor size.

- Attach StiffClip TD to stud per design specifications. Refer to Design Drawings for fastener type, size, and quantity.

Allowable Loads

Load Table Notes

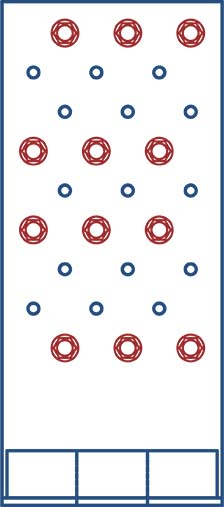

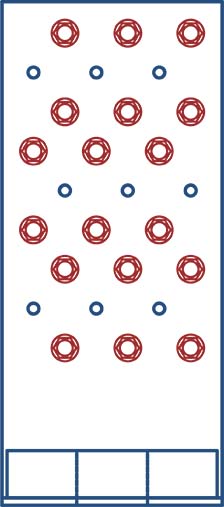

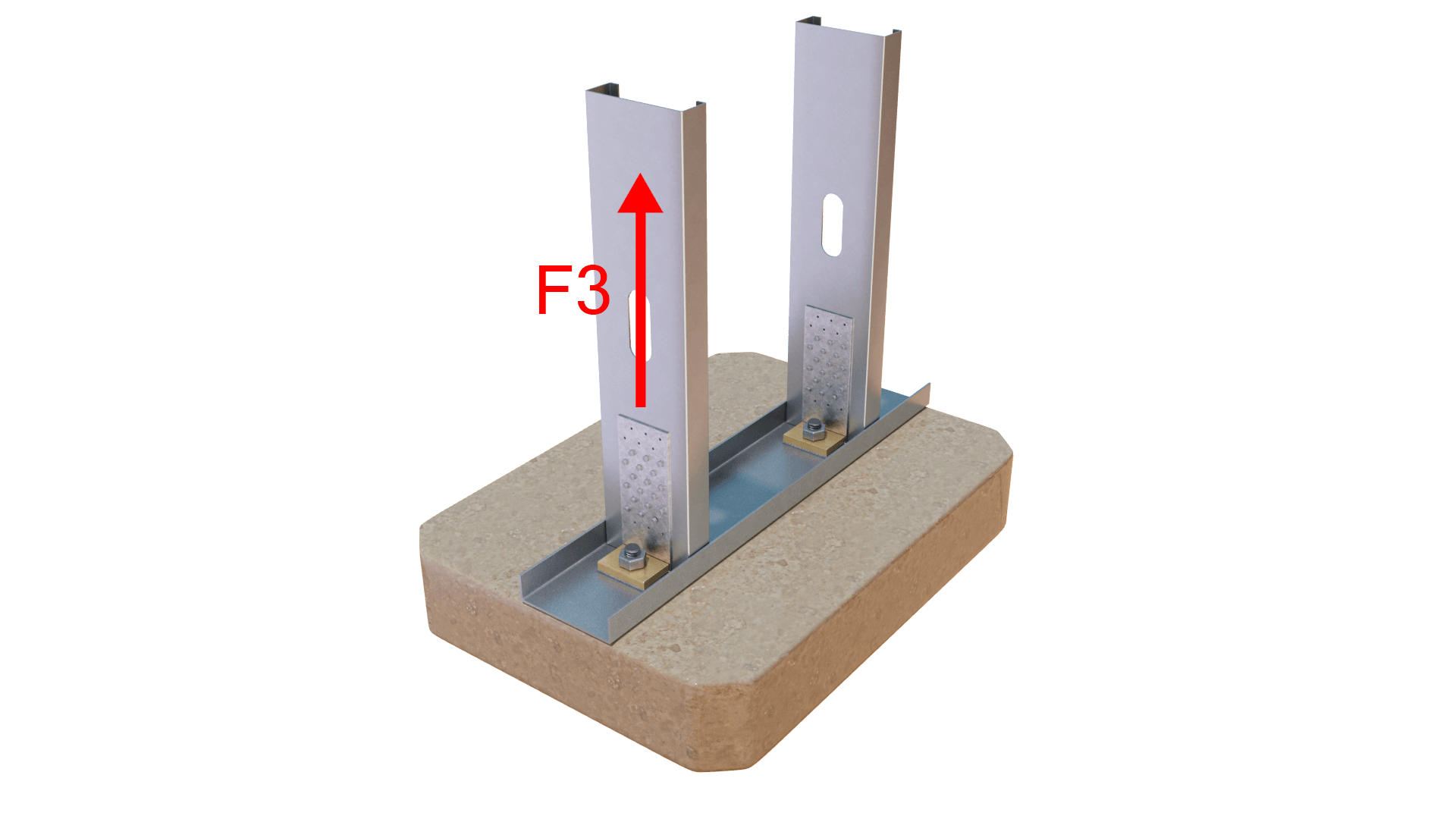

- Design loads are for attachment of StiffClip TD to stud only. Load tables reflect vertical loads (F3).

- Design loads consider loads on the clip and #12 screw fasteners to the stud web for steel framing.

- Design loads consider loads on the clip and listed fasteners to the stud web for wood framing.

- Attachment to structure engineered by others.

- Allowable loads have not been increased for wind, seismic, or other factors.

- Allowable shear for nails and screws is increased 60% for wind and seismic loads in wood framing.

- Fasten within 1-1/4″ from the angle heel using the existing anchor hole.

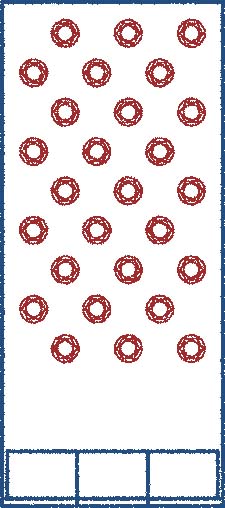

- Guide holes are in place for fastern installation efficiency. The number of fastener are determine by the designer.

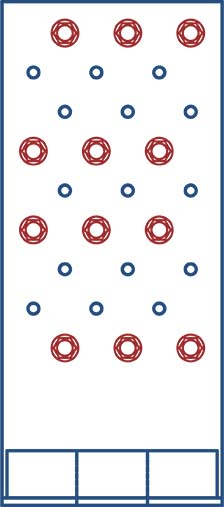

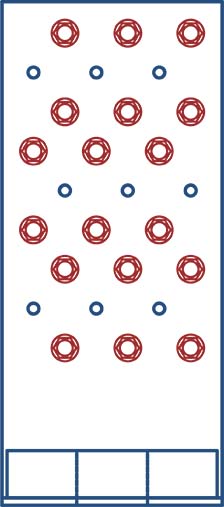

- Attachment to stud is made with up to 27 #12 screws, symmetrically place.

- For wood, moisture content > 19%, consult The Steel Network, Inc. for reduction in values.

- For LRFD strengths contact TSN technical services.

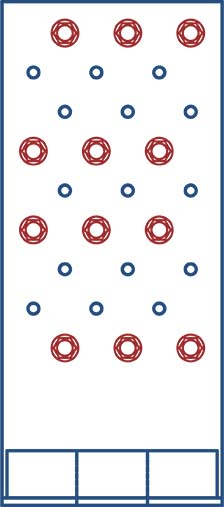

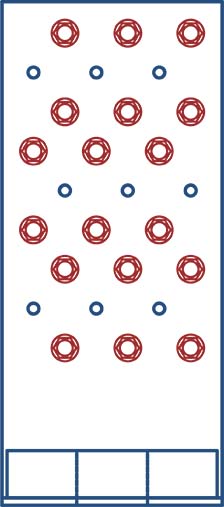

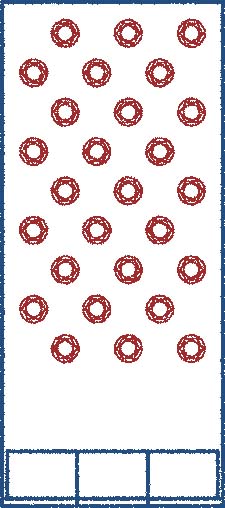

12 Screws

12 Screws 18 Screws

18 Screws 27 Screws

27 Screws 12 Screws

12 Screws 18 Screws

18 Screws 27 Screws

27 Screws 12 Screws

12 Screws 18 Screws

18 Screws 27 Screws

27 Screws

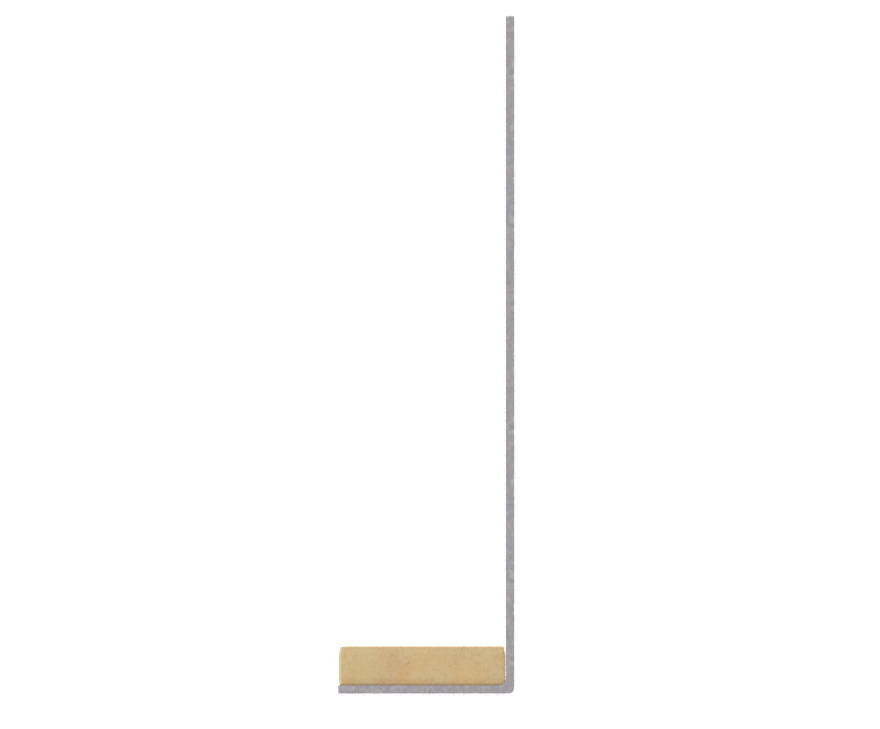

Uplift Diagram

Load Direction

Follow us on Social Media