Schnippel Converts to SigmaStud

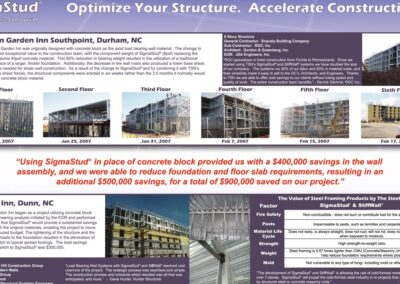

Schnippel Construction is a full-service general contractor in Botkins, Ohio; operating out of the same building since 1953. Back in 2007 a TSN magazine advertisement featuring a hotel built with precast floors and load-bearing cold-formed steel framing members (SigmaStud®) caught Keith Schnippel’s attention. Keith’s father was running the business then, so Keith showed the ad to his father stressing that this is the direction they need to move their hotel projects. Keith believed that gravitating away from load-bearing masonry walls and towards light steel framing load-bearing stud walls would be a game changer for their construction business. Thankfully Keith trusted The Steel Network to guide their way.

The first project TSN and Schnippel did together was stick built steel framing, and that took Schnippel a long time to figure out. Soon, with TSN’s guidance, they moved their efforts to prefabricated panelized walls with SigmaStud®. Today TSN and Schnippel have the construction process so streamlined that Schnippel frames each hotel floor in only two weeks! Schnippel is able to complete the floor framing of a four story hotel from the foundation to the start of the roof in about two months; starting drywall four weeks later.

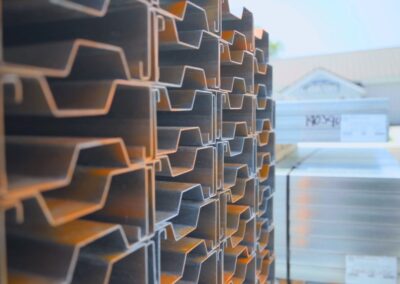

Schnippel continues to take advantage of TSN’s Design Assist Services on their projects, and loves the value it adds to the project so they can get the structural engineers on the same page with the design of SigmaStud®. Since SigmaStud® has unique additional bends in the web of the member, allowing a lighter gauge stud to have increased load capacity for a load-bearing structure, the installers also have lighter weights to move on the jobsite.

Thanks to panelizing with SigmaStud and acting as their own sub-contractor on these hotel projects, Schnippel declares they are saving about 50% on the projects compared to if they subbed it out to a framing contractor who was stick building.

“One of the great advantages of having The Steel Network walls, or the SigmaStud walls, is once we get above that second and third stories, the walls get pretty light gauge and not hard to move. A couple guys can pick them up carry them across the floor set them into place and even getting them up to the upper floors. You can move quite a bit at one time because they don’t weigh very much.”

So we have been doing hotel projects where our load-bearing walls were masonry. I happened to be leafing through a magazine and saw your (TSN) ad of a hotel – precast sitting on metal studs. And at that time (2007) my dad was running the business and I walked in with the ad and said this is where we need to go with the company. This is… this is a gamechanger.

Yes it was a very easy sell. Yes, we reduced our costs and through our efficiencies of panelizing ourselves and not going to – what I would call – a full service subcontractor or framing subcontractor, our costs are typically about half for the SigmaStuds.

Learn More

Learn how The Steel Network, Inc (TSN) can help you convert your next project from wood to light steel framing (LSF) and free spans and open space. TSN will work with your team to evaluate the project and provide you with all of the information you need to switch from wood to LSF and optimize your project.