Steel is widely recognized as the most recycled material on the planet. Recycling of steel has long benefited the industry by saving on raw material costs, reducing the environmental footprint of steel production, and providing feedstocks of benefit to the metallurgical needs of steel producers.

The concept of the Circular Economy has also gained prominence in recent years, bringing attention to many aspects of material end-of-life (EOL) including prolonging product lifespans, improving material efficiency, reuse, remanufacturing and product recycling.

In the technical report, “Determination of Steel Recycling Rates in the United States,” the American Iron and Steel Institute (AISI), the Steel Manufacturers Association (SMA) and Franklin Associates, a Division of Eastern Research Group, present the following recycling rates for 2019:

Overall Steel Recycling Rate

- Based on a three-year rolling average, with rates ranging from 65 to 80 percent since 2012

- Based on a 10-year rolling average, with rates ranging from 71 and 75 percent since 2012

General Construction Steel Recycling Rate

- Rate includes the recycling of both material end-of-life scrap and new scrap. The general construction is a weighted average of the previous three construction sector categories

In their report, AISI and SMA say that the calculation of recycling rates by sector, such as general construction, is subject to some degree of uncertainty since it requires data from a wide variety of sources, some of which is not readily available. The calculated rate above represents the researchers’ best estimates based on multiple data sources and should therefore be a considered reasonable and credible value.

Recycling Rate Methodologies

The Steel Recycling Institute (SRI) was formed in 1988 with the goal of increasing the U.S. recycling rate for steel cans. To measure progress toward that goal, SRI began reporting annual recycling rates for steel cans, using the calculation:

(scrap consumed)/(steel produced)

This basic approach made sense for steel cans, since the lifespan of a steel can is short.

However, SRI eventually began reporting annual overall steel recycling rates and recycling rates for specific sectors, such as construction. Research by Franklin Associates concluded that an alternate methodology would be more appropriate for longer lifespan steel products:

(scrap consumed)/(scrap generated)

Therefore, SRI has adjusted the calculations for the overall and sector rates as follows:

1. New scrap recycling rate:

(new scrap consumed +/- net trades of new scrap)/(new scrap generated)

2. Old scrap recycling rate:

(old scrap consumed +/- net trades of old scrap)/(old scrap generated)

3. Total recycling rate:

(new + old scrap consumed +/- net trades)/(new +old scrap generated)

For more specific information about the recycling rate calculations, the definitions for steel scrap and additional sector-specific recycling rate figures, see “Determination of Steel Recycling Rates in the United States” from AISI.

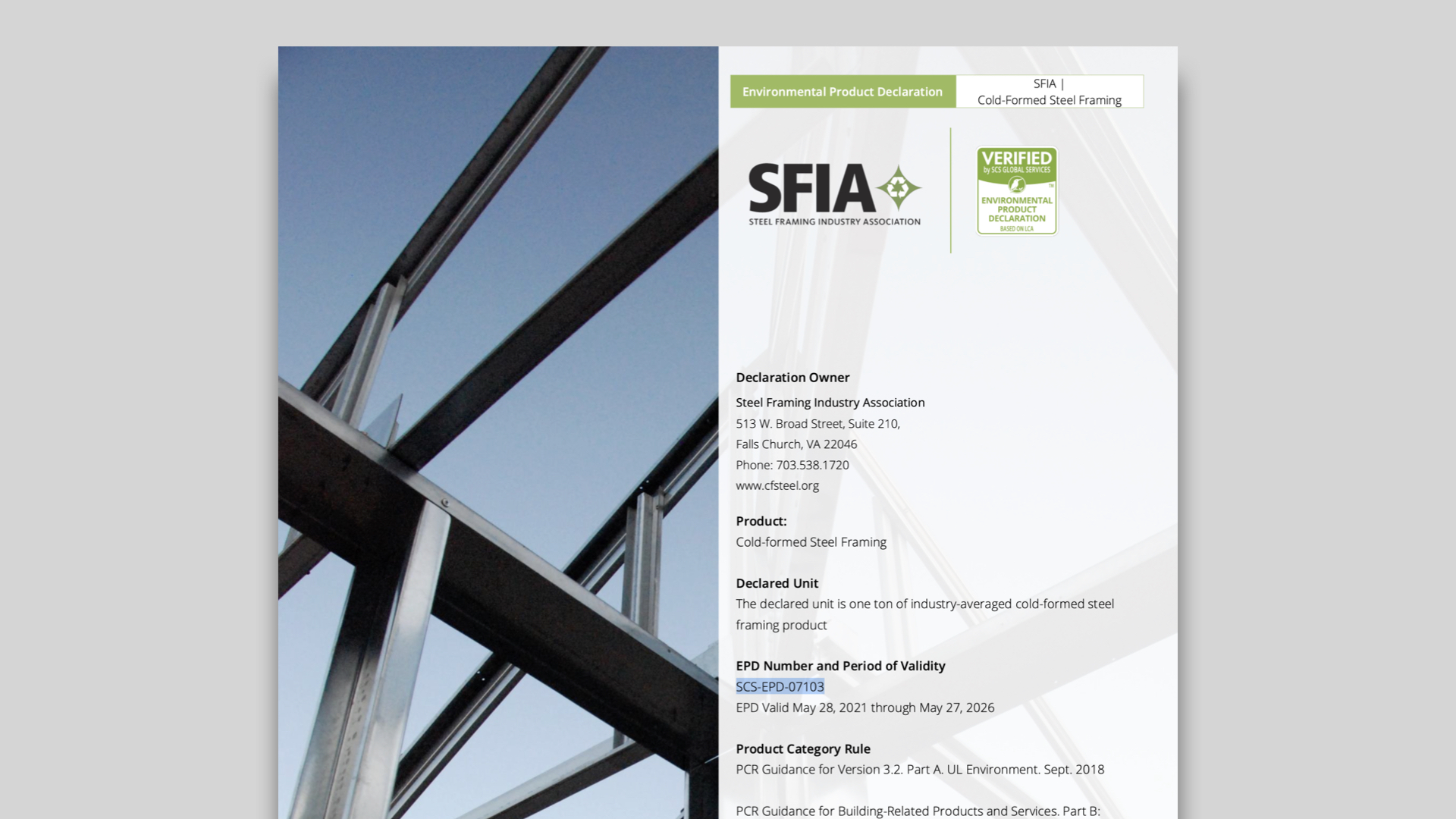

The SFIA Environmental Product Declaration (EPD) for CFS Framing — SCS-EPD-07103, version Sep. 7, 2021 — is good through May 27, 2026.

SFIA Releases Industry Environmental Products Declaration for CFS

The Steel Framing Industry Association (SFIA) has released a new Environmental Product Declaration for Cold-Formed Steel Framing, a tool for contractors, building owners, architects and others delivering advanced building designs that meet the latest LEED™ and other sustainable rating systems, programs and standards.

SFIA EPD for CFS Framing — SCS-EPD-07103, version Sep. 7, 2021 — can be seamlessly integrated into project specifications as an option with company-specific EPDs. SFIA offers a Specifications Review Service for this task. Architects can request the SFIA Specifications Review Service for steel framing, which is a completely free checkup.

Additional Resources

- A Sustainable Home for $177k? It’s Doable with Cold-Formed Steel

- 3 Trends Driving the Construction Industry

- Steel Industry Pushes Toward Net-Zero Energy Target

Article cited by BuildSteel.org