Cold-formed steel (CFS) studs continue to gain popularity in the residential and commercial framing markets. CFS studs are lightweight, impervious to termites, can be cut to precise specifications and never twist or warp. Plus, CFS has the highest strength-to-weight ratio of all structural framing materials — up to 7 times greater than that of dimensional lumber.

“As metal studs become more and more popular throughout various construction applications, learning more about light gauge studs, and where to use them can make your next project a success,” says Roger Kint, writer for Drywall Insider.

To ease the learning curve, Klint provides a guide to realize the many benefits of steel framing and understand the basics to be ready for your next project.

What Are Cold-Formed Steel Studs?

CFS framing is made from strips of structural quality sheet steel that are fed through roll forming machines to meet the requirements of specific applications.

CFS, also called light-gauge steel or metal stud framing, is typically referred to as light-framed construction. The vertical and horizontal structural elements are primarily formed by a system of repetitive framing members. The framing members are typically spaced at 16 or 24 inches on center, the spacing variations depending upon the loads and coverings.

A variety of CFS thicknesses are available to meet a wide range of structural and non-structural applications (range from 0.0147 inches to about 1/8 inch). Standard CFS products are defined in AISI S201, North American Standard for Cold-Formed Steel Framing – Product Data, 2012 Edition.

CFS is increasingly being used as the primary structural system for buildings 10-plus stories. It is also gaining use in the framing of single-family homes. A variety of CFS framing products are available from various manufacturers.

Steel Framed-Home Built to Last Over 100 Years

A modern home being built outside of Toronto, featuring CFS framing, provides an example of how today’s innovative contractors are using improved practices to construct homes that will last a century and beyond.

Located in Mississauga, Ontario, the residence on Doulton Drive will have “a completely noncombustible rigid steel frame and solid concrete floors,” says the website for homebuilder, Chatsworth Fine Homes, Oakville, Ontario.

“The architect designed this home to have a life expectancy of more than 100 years,” says Fil Capuano, president of Chatsworth Fine Homes. “Resilient products like the steel framing system were carefully chosen to meet that life span.”

The home features a hybrid system that combines structural steel and CFS wall framing. The interior partitions will make use of CFS framing and wallboard.

“It’s in-fill framing using all wind-bearing metal studs,” says Chris Sliskovic, president of Life Drywall Systems, Ltd., an Oakville, Ontario residential and commercial contractor that has the framing, drywall and finishing contract for the project.

“Those walls and reveals, no matter the finish, will always be straight,” Sliskovic says. “Steel doesn’t warp. It doesn’t twist. The homeowner won’t ever get nail pops. And for sound, it’s just a no-brainer — the walls will be finished next to perfection.”

How are Steel Studs Made?

CFS is made from structural quality sheet steel formed into C-sections and other shapes usually by roll-forming the steel through a series of dies. No heat is required to form the shapes (unlike hot-rolled steel), hence the name cold-formed steel.

SFIA member Telling Industries provides an inside look at steel stud production.

The Benefits of Steel Framing Over Wood

“Many skilled carpenters will agree that metal studs are often much easier to work with than wood studs,” says Klint. “A wood stud wall is cumbersome and heavy.”

Little Cutting, Reduced Waste

CFS framing is similar to wood. But, it is manufactured to precise lengths, so very little cutting and sizing occurs at the job site.

“Steel studs, tracks, and channels can be ordered in specific quantities with exact measurements from steel roll formers, creating less waste.” says Clint. “Once they arrive at a job site, most steel studs for wall framing fit together, so they’re easily stackable.”

A South Valley Prefab craftsman inspects the quality of a prefabricated exterior wall panel.

Durability

Steel is dimensionally stable and does not expand or contract with changes in moisture content. Steel will not warp, split, crack or creep when exposed to the elements.

“Unlike wood, light gauge steel is damp proof and won’t rot,” says Clint. “Steel doesn’t easily hold mold or harbor insects — it won’t warp from water damage or burn up”

Sustainable

Every piece of CFS framing contains recycled content and meets the highest sustainability requirements of all major green building standards and rating programs.

CFS Meets All Sustainability Requirements

Cold-formed steel (CFS) meets the highest sustainability requirements set in all major green building standards and rating programs, including the Leadership in Energy and Environmental Design (LEED®) from the U.S. Green Building Council, the National Green Building Standard (ICC-700) for residential buildings, ASHRAE Standard 189.1 for commercial construction and the International Green Construction Code (IgCC).

The American Iron and Steel Institute reports:

- Steel framing contains a minimum of 25% recycled steel and is continually and completely “remade without any loss of quality”

- Most other construction products can only be down-cycled into lower-quality products

- Steel framing minimizes construction site waste

Who Manufactures Steel Studs?

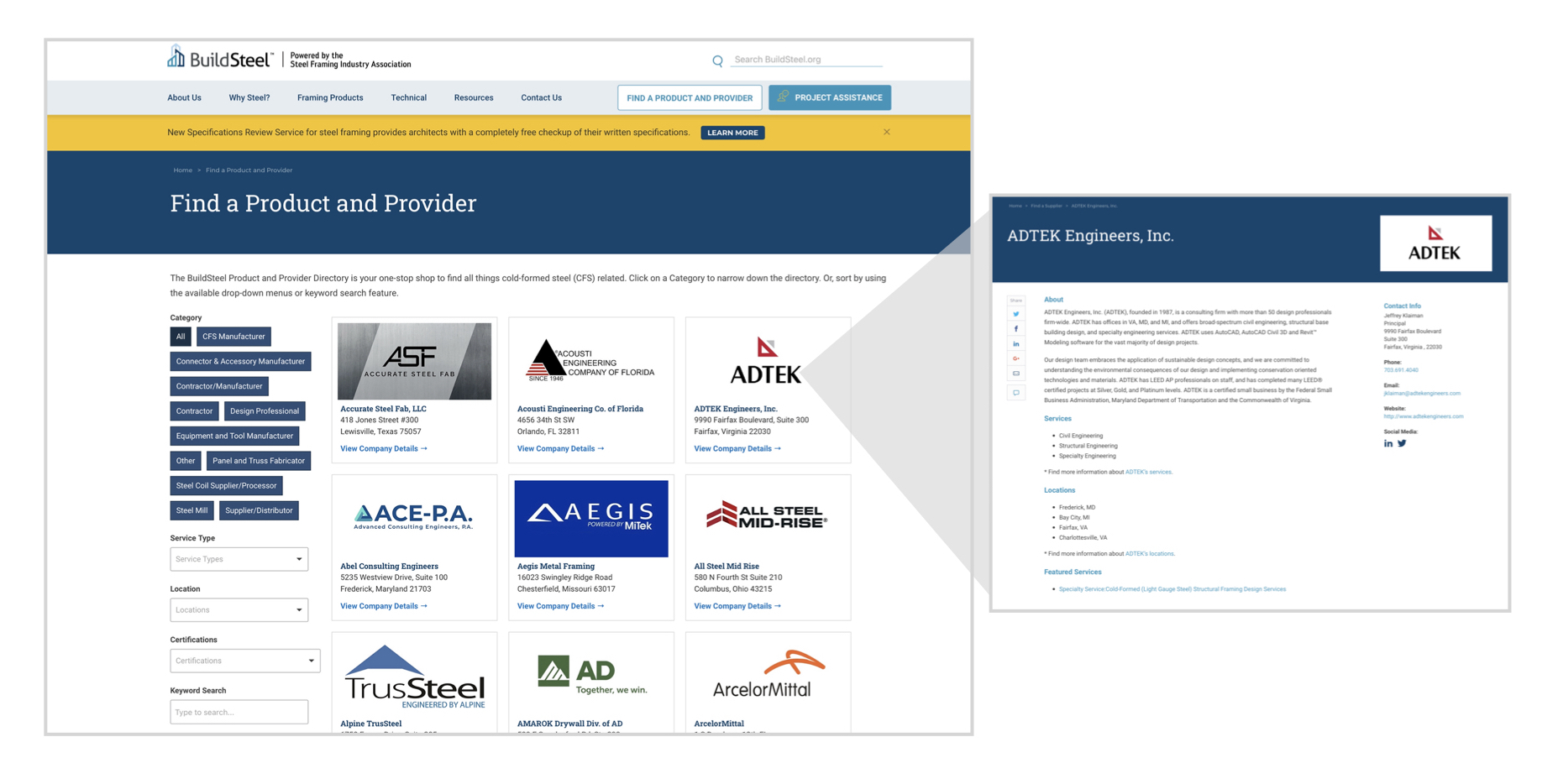

The BuildSteel Product and Provider Directory is your one-stop shop to find all things CFS related. The directory allows users to search by category, service type, location or certification type.

Free Project Assistance

Need support for a new or existing project in the U.S. and Canada? Use BuildSteel’s free project assistance for CFS framing:

- Convert from wood framing, masonry or concrete to steel

- National network of contractors, suppliers and manufacturers

- Industry experts with decades of knowledge on CFS

- Central source for consultation on code-compliant design

Simply fill out our project assistance form. We will provide you with an expert based on the needs of your project.

Additional Resources

- 10 Reasons to Frame Your Next Project with Steel

- Free On-Demand Webinar: Cold-Formed Steel in Mid-Rise Construction

- How Cold-Formed Steel and Structural Steel Are Alike – and Different

Cited from BUILDSTEEL.ORG