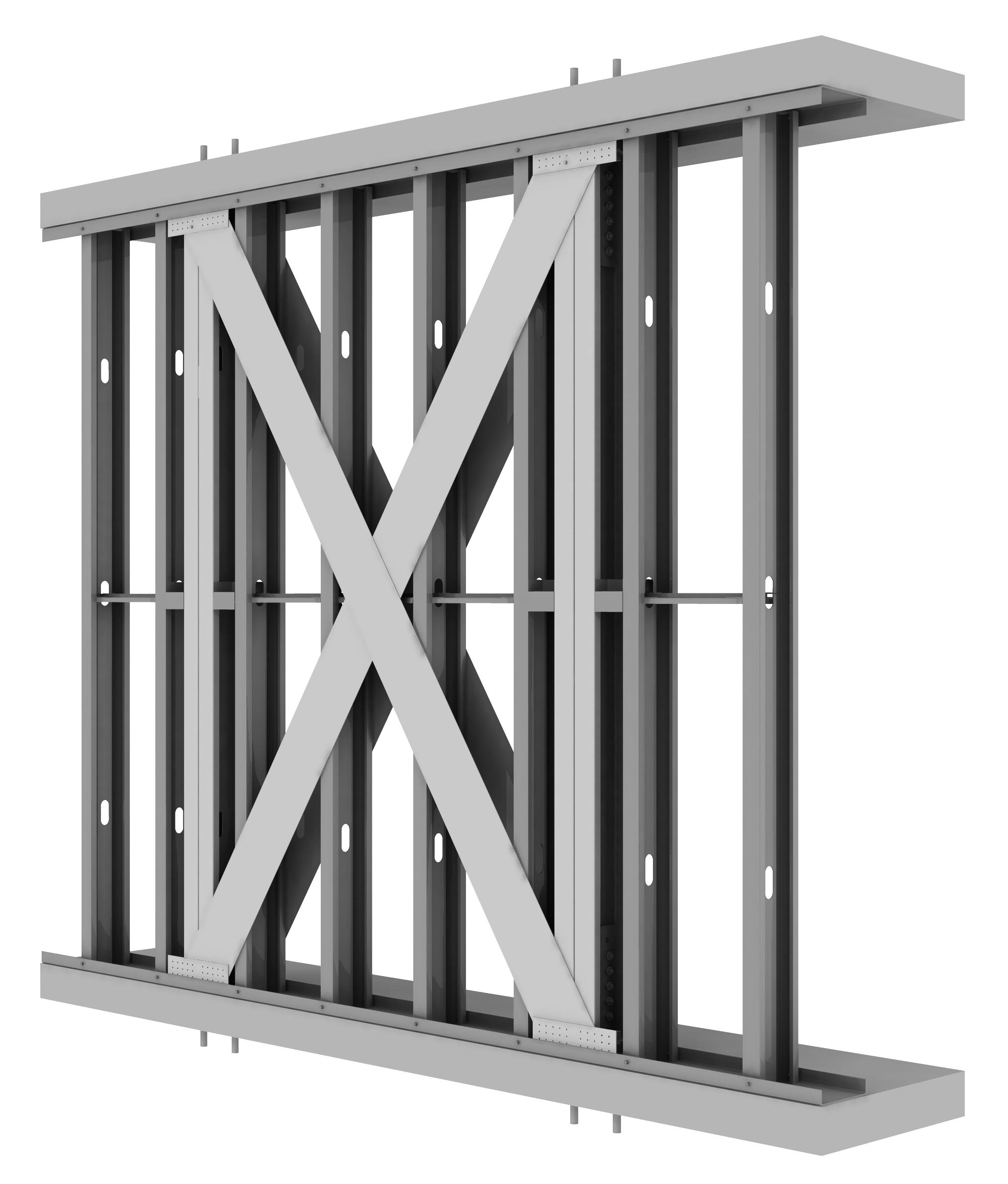

StiffWall® Shear Wall System

StiffWall provides superior quality with high yield ASTM A1003 steel and hot-dipped galvanized coating for long-term durability. The design is ideal for job specific sizes with established load requirements. The Steel Network has optimized the design and fabrication of StiffWall through a series of both component and full-scale wall assembly tests, using state of the art technology to measure performance.

Features

- Designed and manufactured to meet the performance requirements of the project.

- Satisfies maximum story drift requirements per IBC.

- Tested for multi-story application and capable of carrying loads present in 10 story buildings.

- Allows 3 times the window space of plywood braced structures.

- Templates are not required for hold-downs, eliminating unrealistic field procedures.

- Plywood sheathing with fastener schedules and/or CMU shear walls are eliminated.

- Inspection is limited to simple connections at corners.

- Versatile design may be incorporated into steel, concrete, or wood construction.

- No welds or controlled inspections associated with welding.

- Simplified anchoring system through floors and at roof termination.

- The strap system is on the outside of the wall to facilitate electrical and pipe work in the wall cavity.

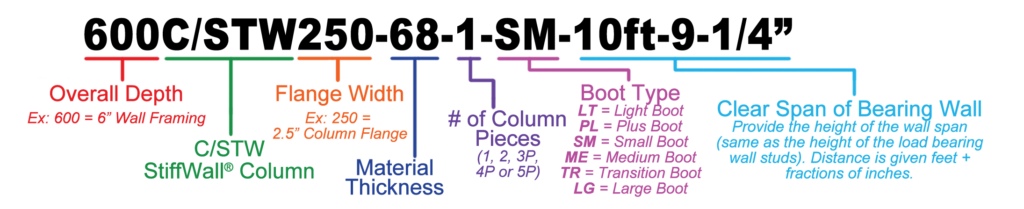

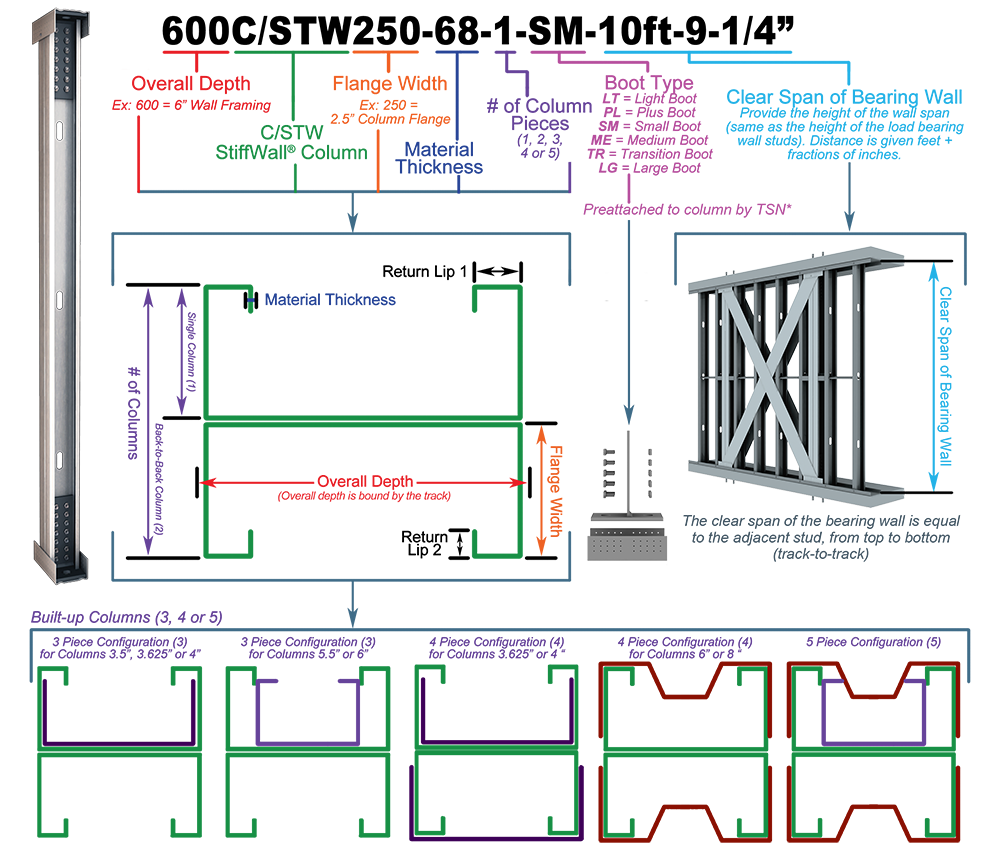

Nomenclature

Call your TSN Sales Representative at 1-888-474-4876 for Assistance Ordering

Material Composition

Columns: ASTM A1003/A1003M or ASTM A653/A653M, Grade 50 (340), 50ksi (340MPa) minimum yield strength, 65ksi (450 MPa) minimum tensile strength, G-60 (Z180) hot-dipped galvanized coating; or equivalent.

Structural Steel Boots: ASTM A 572/A 572M, Grade 50 or equivalent (Min. Fy = 50 ksi, Min. Fu = 65 ksi). Coating Powder – Black or TSN approved equivalent.

Strap Track: ASTM A 1003/A 1003M, ST50H or equivalent (Min. Fy = 50 ksi, Min. Fu = 65 ksi)

Bolts: ASTM F3125 Grade A325

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. StiffWall® can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

StiffWall® Shear Wal System Downloads

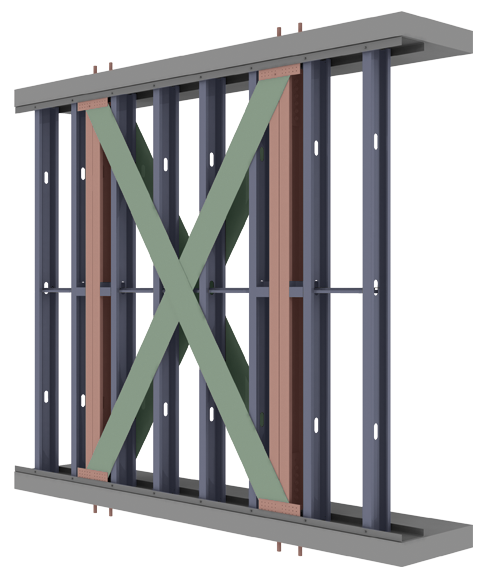

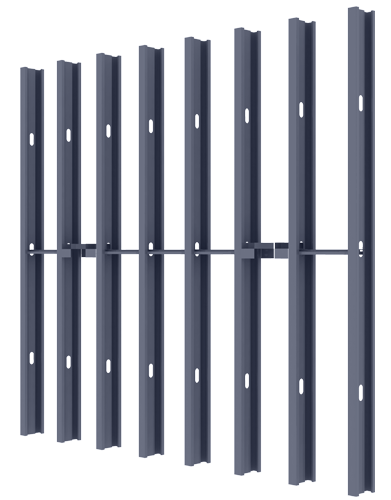

StiffWall® Shear Wall System Components

Call your TSN Sales Representative at 1-888-474-4876 for Assistance Ordering

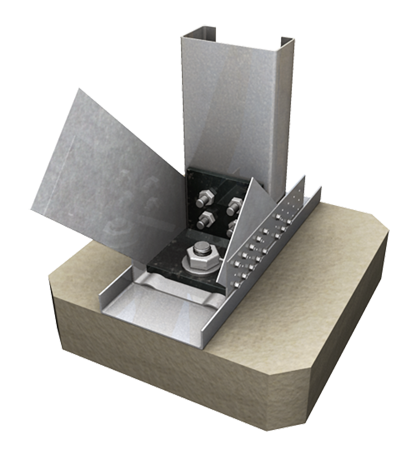

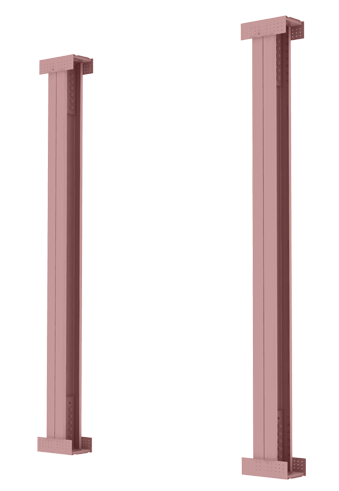

Column/Boot Assembly

These are preassembled by TSN and installed at each end post of the shear wall

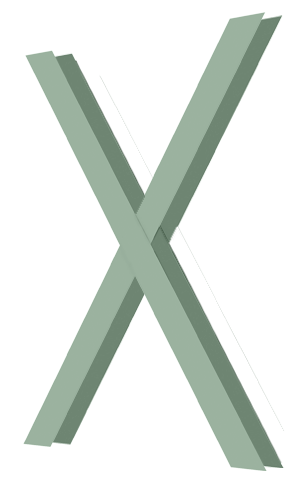

Flat Strap X-Bracing

Two straps make up the X-Bracing on each side of the shear wall for a total of four straps per shear wall.

Loadbearing Wall

SigmaStud & Bucklebridge or other loadbearing studs and bridging can be used (not part of StiffWall)

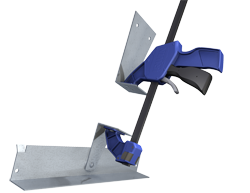

TightStrap

Tensioning tool used to properly tighted Flat Strap X-Bracing prior to screwing to StiffWall Column/Boot Assembly

Installation Instructions

- Position tracks and nest the pre-assembled StiffWall® Column Assemblies into the track over the anchors.

- Install required infill studs until the next StiffWall Column is encountered.

- Install required bridging as specified, adjusting for the StiffWall Columns.

- Align Flat Strap X-Bracing. Use a single screw to hold each corner in place prior to loading.

- For multiple floors, through rods will extend through floor and into the StiffWall Assembly to the next floor.

- Ensure StiffWall Column alignment for full bearing of the through rods with the floor slab.

- After constructing multiple floors, tighten each Flat Strap, utilizing the TSN TightStrap® Tensioning Tool, if available.

- Secure with evenly distributed #12 screws, as specified.

How to order StiffWall Column Boot Assemblies

- Select the Overall Wall Depth:

- Available Options: 3.5″ (350), 3.625″ (362), 4″ (400), 5″ (550), 6″ (600), or 8″ (800)

- Example: 6″ Wall Framing = 600

- Select Section Type “C/STW”: Like “S”, “T”, “JAM”, or “SGT.” This designates the StiffWall Column section and it is the same for all StiffWall Columns.

- Example: C/STW

- Select the Flange Width:

- Available Options: 2″ (200) or 2.5″ (250)

- Example: 2.5″ Flange Width = 250

- Select Material Thickness

- Available Options: 33mil, 43mil, 54mil, 68mil, 97mil, or 118mil.

- Example: 68mil Thickness = 68

- Select Column Configuration:

- Available Options: 1, 2, 3, 4, or 5 (See Column Chart)

- Example: 1 Column = 1

- Select Boot Type:

- Available Options: Light (LT), Plus (PL), Small (SM), Medium (ME), Transition (TR), or Large (LG).

- Example: Small Boot = SM

- Determine Clear Span of the Bearing Wall: This is the height from top to bottom track and is the same height as the loadbearing studs in the same wall.

- Example: 10ft9.24″ = 10ft-9-1/4″

- Result: TSN will manufacture a 600C/STW250-68-1-SM-10ft-9-1/4″. You will need to order 2 of these per shear wall.

Call your TSN Sales Representative at 1-888-474-4876 for Assistance Ordering

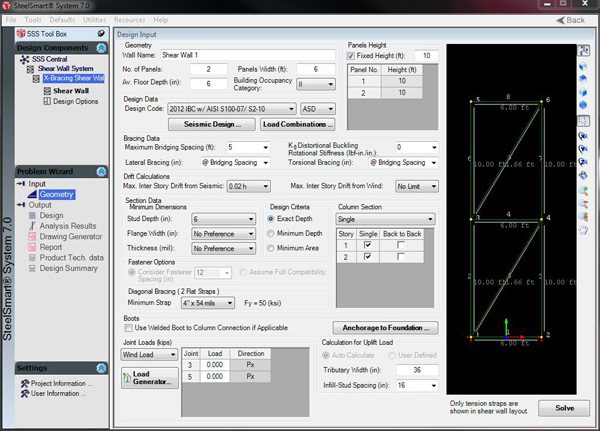

How to Design StiffWall X-Braced Shear Walls

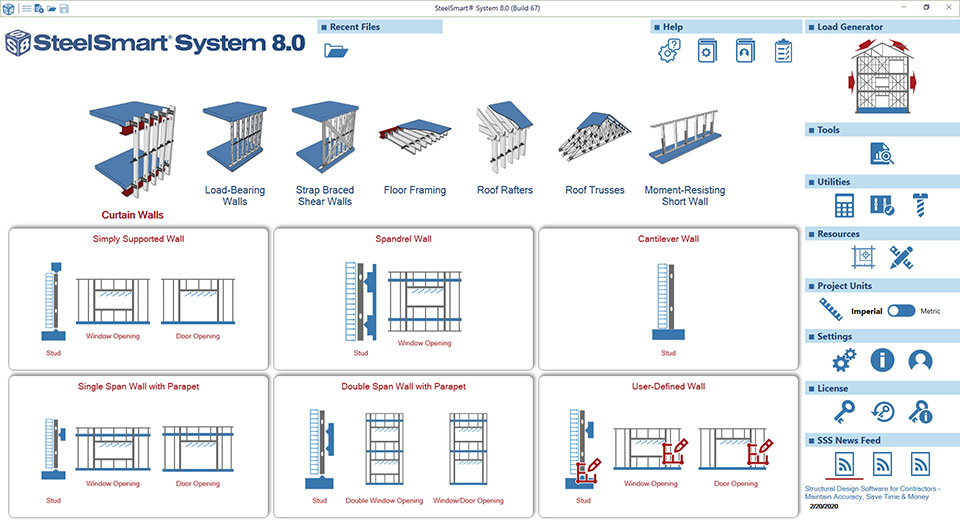

The simplest way to design TSN’s StiffWall X-Braced Shear wall is to utlize the X-Braced Shear Wall design module in SteelSmart System. Lateral and vertical loads for wind, seismic, and snow can also be automatically calculated based on your building’s shape and be imported into the X-Braced Shear Wall module to streamline shear wall design.

SteelSmart® System

SteelSmart System (SSS) provides structural engineers with a structural design software tool engineered for optimal design and detailing of light steel framing studs, joists, shear walls, and connectors.

X-Braced Shear Wall Design

Module

SteelSmart® System’s X-Brace Shear Wall design module enables users to quickly design the innovative StiffWall® shear wall system as an alternative shear wall system.

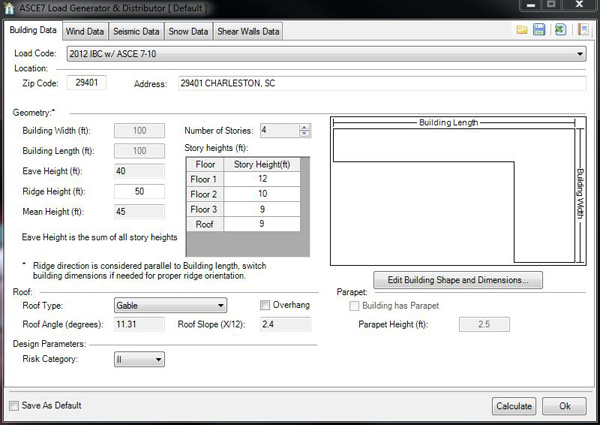

Load Generator and Distributor

The Load Generator and Distributor tool uses the dimensions and load specification for a building to calculate automatically the lateral wind and seismic forces according to ASCE 7 “Minimum Design Loads for Buildings and Other Structures” using the project zip code.

Follow us on Social Media