Photo Credits: The Steel Network

The Element by Weston is a 7-story hotel located in Chattanooga, Tennessee. The Steel Network (TSN), a member of the SFIA, supplied load-bearing cold-formed steel (CFS) framing for the construction of the 131-room hotel. By using CFS, the construction time per floor was reduced from weeks to days, saving time and money for the construction of the hotel.

Efficient Load-Bearing Walls

The $24 million hotel project featured the use of TSN’s SigmaStud® for the light steel framed walls of the Element by Weston.

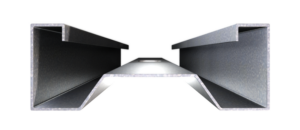

According to the TSN website, SigmaStud’s are load-bearing steel stud members that produce increased load capacity when compared with conventional “C” shaped metal studs. Their unique configuration provides installation and design advantages which create efficiencies for load-bearing walls.

SigmaStud’s load-bearing steel studs produce increased load capacity when compared with conventional “C” shaped metal studs.

Each bend made to a flat piece of light gauge metal increases load capacity over a standard stud section with the same material thickness – 6 extra bends result in delivering a more efficient light load-bearing stud member.

For the Element Hotel, SigmaStuds allowed the installers to use a lighter gauge material that was easier to install and did not require the lengthy drying time of block and plank construction.

Project Completed 3-Months Early

Lucas Drywall, a certified level 5 drywall installer and finisher, leveraged TSN’s products to reduce construction time required for the project.

In the early design phases, Lucas Drywall worked with TSN to analyze different types of building materials. They compared the use of load-bearing metal studs to traditional CMU block, more commonly called block and plank.

“Technically, those floors (CMU block) take a mason three weeks to stand up and grout,” said Jason Patel, vice president of Lucas Drywall. “The benefit of using load-bearing cold-formed metal studs was we’re able to bring the building up faster.“

Load-bearing steel framing, combined with hollow core floors, was easier to install and did not require the lengthy drying time of block and plank construction.

By using steel framing, Lucas Drywall was able to reduce construction time per floor from 3 weeks to 3 days.

“We are flying the walls in 2 days and we are temporary, bracing and getting them ready the third day,” said Patel. “So typically we’re turning that floor now in 3 days versus the traditional method that would have taken 3 weeks per floor.”

Over the course of the 7-story project, Patel estimated that the project was completed 3 months earlier using CFS framing.

View additional photos of this project and learn more about TSN’s solutions for all standard light steel framing applications, including load-bearing mid-rise construction systems, curtain wall systems, rigid connectors, vertical deflection connectors, lateral drift connectors and short wall connectors.

Cited from BuildSteel