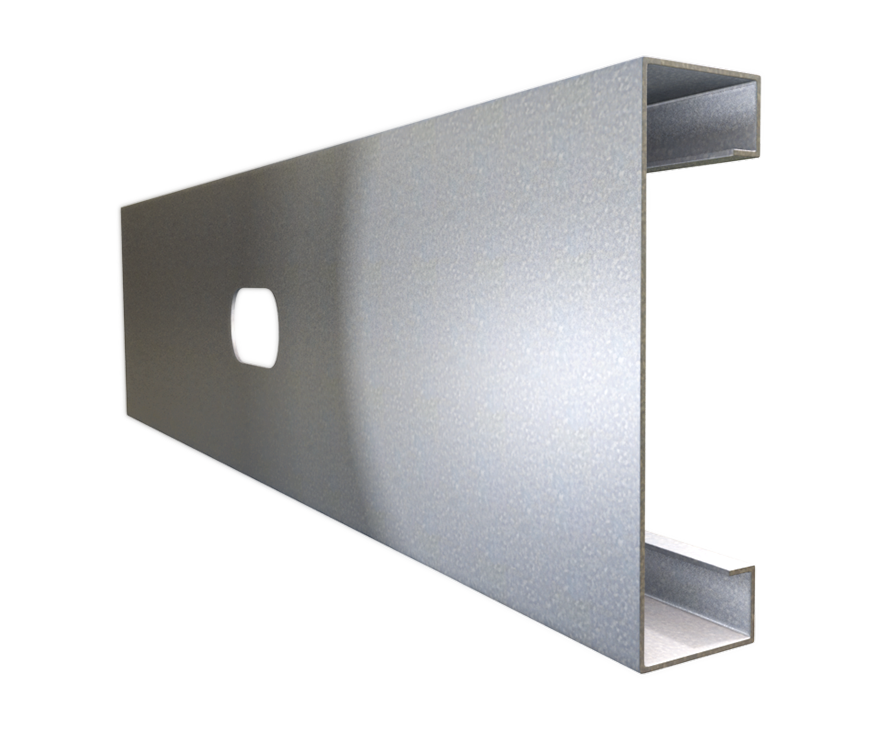

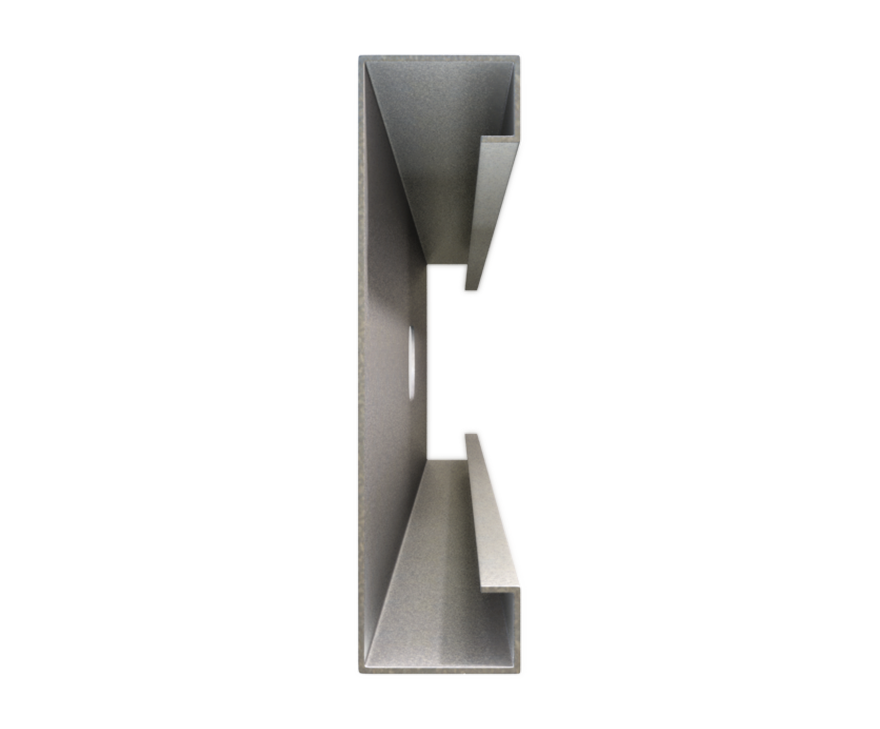

PrimeJoist®

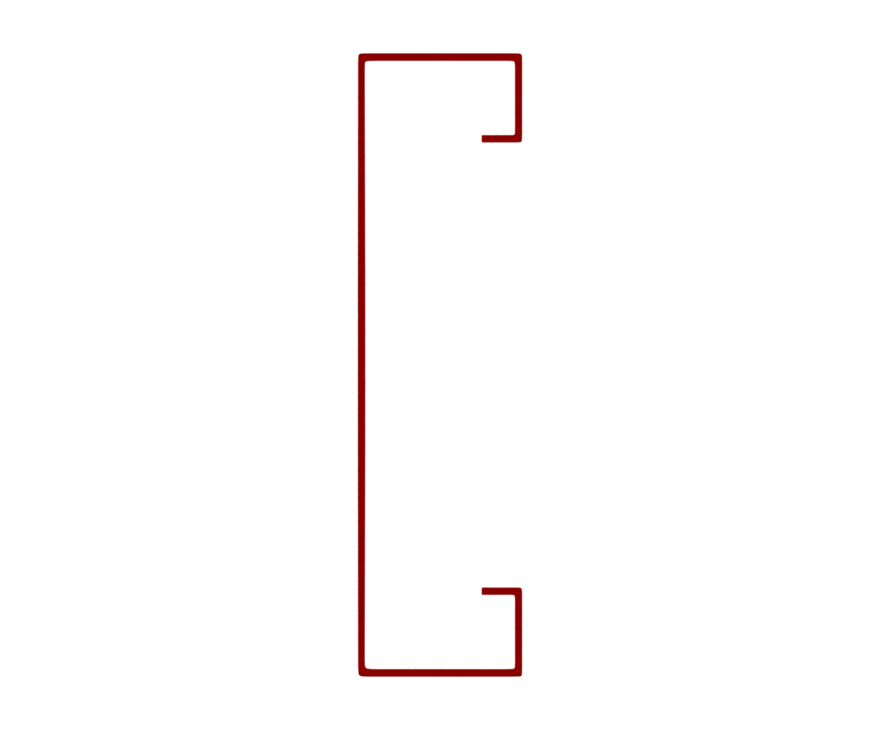

PrimeJoist produces significant economies in both design and installation when compared with conventional “C” Shaped joists. PrimeJoist’s unique configuration delivers increased strength and stiffness, minimizing or eliminating the use of built-up joist sections in floor assemblies.

Available in all common floor joist depths, PrimeJoist streamlines the design and construction process. PrimeJoist’s shape is easily differentiated from the typical c-shape, enabling the selection of the most optimal member sizes to fit project conditions.

Features

- Increases load capacity over a standard “C-shaped” joist of the same thickness

- Enables selection of optimal thickness of flooring members and reduction in joist packs required, simplifying floor sysetem design & reducing overall materials needed

- Lighter weight results in shipping efficiencies and easier handling

- No welding or fastening built-up members (joist packs) together

Nomenclature

Material Composition

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. PrimeJoist® can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

PrimeJoist® Downloads

PrimeJoist® Application

Cold-formed Steel Floor Joist

Installation Instructions

- Place MasterClip® angle against structural pour stop.

- Attach VLB to structure with required fasteners.

- For vertical deflection connection: Fasten VLB to stud with provided screws through integrated Step Bushings.

- For rigid connection: Fasten VLB to stud with required screws through pre-drilled guide holes.

|

|

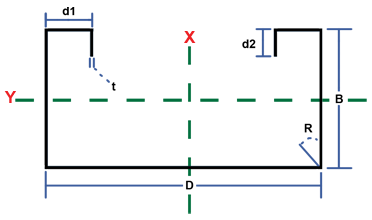

| PrimeJoist® Product Profile | |||||||

| Section (All 50 ksi) |

Overall Depth | Flange Width | Return Lip 1 | Return Lip 2 | Inside Bend | Design Thickness | Unit Weight |

| D | B | d1 | d2 | R | t | (lbs/ft) | |

| (in) | (in) | (in) | (in) | (in) | (in) | ||

| 600PJ250-33 | 6 | 2.5 | 0.589 | 0.5 | 0.105 | 0.0346 | 1.49 |

| 600PJ250-43 | 6 | 2.5 | 0.61 | 0.5 | 0.105 | 0.0451 | 1.94 |

| 600PJ250-54 | 6 | 2.5 | 0.633 | 0.5 | 0.105 | 0.0566 | 2.42 |

| 600PJ250-68 | 6 | 2.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 3.04 |

| 600PJ250-97 | 6 | 2.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 4.3 |

| 600PJ250-118 | 6 | 2.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 5.22 |

| 600PJ350-68 | 6 | 3.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 3.53 |

| 600PJ350-97 | 6 | 3.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 5 |

| 600PJ350-118 | 6 | 3.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 6.06 |

| 800PJ250-43 | 8 | 2.5 | 0.61 | 0.5 | 0.105 | 0.0451 | 2.24 |

| 800PJ250-54 | 8 | 2.5 | 0.633 | 0.5 | 0.105 | 0.0566 | 2.81 |

| 800PJ250-68 | 8 | 2.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 3.53 |

| 800PJ250-97 | 8 | 2.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 5 |

| 800PJ250-118 | 8 | 2.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 6.06 |

| 800PJ350-68 | 8 | 3.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 4.01 |

| 800PJ350-97 | 8 | 3.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 5.69 |

| 800PJ350-118 | 8 | 3.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 6.9 |

| 1000PJ250-43 | 10 | 2.5 | 0.61 | 0.5 | 0.105 | 0.0451 | 2.55 |

| 1000PJ250-54 | 10 | 2.5 | 0.633 | 0.5 | 0.105 | 0.0566 | 3.19 |

| 1000PJ250-68 | 10 | 2.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 4.01 |

| 1000PJ250-97 | 10 | 2.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 5.69 |

| 1000PJ250-118 | 10 | 2.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 6.9 |

| 1000PJ350-68 | 10 | 3.5 | 0.663 | 0 .5 | 0.105 | 0.0713 | 4.5 |

| 1000PJ350-97 | 10 | 3.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 6.38 |

| 1000PJ350-118 | 10 | 3.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 7.75 |

| 1200PJ250-54 | 12 | 2.5 | 0.633 | 0.5 | 0.105 | 0.0566 | 3.58 |

| 1200PJ250-68 | 12 | 2.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 4.5 |

| 1200PJ250-97 | 12 | 2.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 6.38 |

| 1200PJ250-118 | 12 | 2.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 7.75 |

| 1200PJ350-68 | 12 | 3.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 4.98 |

| 1200PJ350-97 | 12 | 3.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 7.07 |

| 1200PJ350-118 | 12 | 3.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 8.59 |

| 1400PJ250-54 | 14 | 2.5 | 0.633 | 0.5 | 0.105 | 0.0566 | 3.96 |

| 1400PJ250-68 | 14 | 2.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 4.98 |

| 1400PJ250-97 | 14 | 2.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 7.07 |

| 1400PJ250-118 | 14 | 2.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 8.59 |

| 1400PJ350-68 | 14 | 3.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 5.47 |

| 1400PJ350-97 | 14 | 3.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 7.76 |

| 1400PJ350-118 | 14 | 3.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 9.44 |

| 1600PJ250-68 | 16 | 2.5 | 0.663 | 0.5 | 0.105 | 0.0713 | 5.47 |

| 1600PJ250-97 | 16 | 2.5 | 0.723 | 0.5 | 0.105 | 0.1017 | 7.76 |

| 1600PJ250-118 | 16 | 2.5 | 0.768 | 0.5 | 0.105 | 0.1242 | 9.44 |

Notes:

- Effective properties incorporate the strength increase from the cold-work of forming as applicable per AISI A7.2.

- Tabulated gross properties are based on the full-unreduced cross section of the studs, away from punchouts.

- Tabulated gross properties are based on the full-unreduced cross section of the studs, away from punchouts.

- Allowable moment is the lesser of Mal and Mad. Stud distortional buckling is based on an assumed kΦ = 0.

- For deflection calculations, use the effective moment of inertia.

- The effective moment of inertia for deflection is calculated at a stress which results in a section modulus such that the stress times the section modulus at that stress is equal to the allowable moment. AISI S100-07 Procedure I for serviceability determination has been used.

| PrimeJoist® Section Properties | |||||||||||||||||||

| Section (All 50 ksi) |

Gross Properties | Effective Properties | Torsional Properties | Lu | |||||||||||||||

| Area | Ix | Sx | Rx | Iy | Ry | Ixe | Sxe | Mal | Mad | Vag | Va(net) | Jx1000 | Cw | Xo | m | Ro | ß | ||

| (in2) | (in4) | (in3) | (in) | (in4) | (in) | (in4) | (in3) | (kips-in) | (kips-in) | (lbs) | (lbs) | (in4) | (in6) | (in) | (in) | (in) | (in) | ||

| 600PJ250-332 | 0.438 | 2.522 | 0.841 | 2.4 | 0.402 | 0.958 | 0.175 | 3.209 | -2.094 | 1.269 | 3.326 | 0.604 | 53.3 | ||||||

| 600PJ250-43 | 0.569 | 3.261 | 1.087 | 2.394 | 0.519 | 0.955 | 3.239 | 0.919 | 27.5 | 23.66 | 1,432 | 1,235 | 0.386 | 4.15 | -2.088 | 1.266 | 3.317 | 0.604 | 53.3 |

| 600PJ250-54 | 0.712 | 4.058 | 1.353 | 2.387 | 0.644 | 0.951 | 4.058 | 1.174 | 35.14 | 32.38 | 2,843 | 1,942 | 0.76 | 5.163 | -2.082 | 1.263 | 3.307 | 0.604 | 53.4 |

| 600PJ250-68 | 0.894 | 5.055 | 1.685 | 2.378 | 0.801 | 0.947 | 5.055 | 1.526 | 45.68 | 44.25 | 5,350 | 2,882 | 1.514 | 6.431 | -2.074 | 1.259 | 3.295 | 0.604 | 53.5 |

| 600PJ250-973 | 1.265 | 7.047 | 2.349 | 2.361 | 1.111 | 0.937 | 7.047 | 2.305 | 77.07 | 76.03 | 10,653 | 3,964 | 4.36 | 8.956 | -2.058 | 1.25 | 3.269 | 0.604 | 53.8 |

| 600PJ250-1183 | 1.533 | 8.447 | 2.816 | 2.348 | 1.327 | 0.93 | 8.447 | 2.816 | 95.91 | 95.91 | 12,905 | 3,888 | 7.855 | 10.726 | -2.045 | 1.244 | 3.25 | 0.604 | 54.1 |

| 600PJ350-68 | 1.036 | 6.309 | 2.103 | 2.467 | 1.799 | 1.318 | 6.023 | 1.628 | 48.76 | 47.85 | 5,350 | 2,882 | 1.756 | 14.285 | -3.006 | 1.771 | 4.106 | 0.464 | 71.5 |

| 600PJ350-97 | 1.468 | 8.816 | 2.939 | 2.451 | 2.513 | 1.308 | 8.729 | 2.534 | 75.86 | 77.71 | 10,653 | 3,964 | 5.061 | 20.02 | -2.99 | 1.763 | 4.081 | 0.463 | 72 |

| 600PJ350-118 | 1.781 | 10.588 | 3.529 | 2.438 | 3.017 | 1.302 | 10.588 | 3.341 | 100.02 | 100.89 | 12,905 | 3,888 | 9.127 | 24.09 | -2.978 | 1.757 | 4.063 | 0.463 | 72.5 |

| 800PJ250-43 | 0.659 | 6.378 | 1.595 | 3.11 | 0.572 | 0.931 | 6.368 | 1.225 | 36.66 | 32.25 | 1,060 | 1,060 | 0.447 | 7.513 | -1.869 | 1.159 | 3.746 | 0.751 | 52.3 |

| 800PJ250-54 | 0.825 | 7.949 | 1.987 | 3.103 | 0.71 | 0.927 | 7.949 | 1.7 | 50.89 | 44.46 | 2,102 | 2,102 | 0.881 | 9.34 | -1.862 | 1.156 | 3.736 | 0.752 | 52.2 |

| 800PJ250-68 | 1.036 | 9.923 | 2.481 | 3.095 | 0.883 | 0.923 | 9.923 | 2.26 | 67.68 | 61.31 | 4,219 | 3,368 | 1.756 | 11.624 | -1.854 | 1.151 | 3.724 | 0.752 | 52.2 |

| 800PJ250-973 | 1.468 | 13.893 | 3.473 | 3.076 | 1.225 | 0.914 | 13.893 | 3.409 | 113.95 | 106.91 | 10,885 | 6,032 | 5.061 | 16.161 | -1.838 | 1.142 | 3.698 | 0.753 | 52.2 |

| 800PJ250-1183 | 1.781 | 16.707 | 4.177 | 3.063 | 1.464 | 0.907 | 16.707 | 4.177 | 142.27 | 140.45 | 16,235 | 7,312 | 9.127 | 19.33 | -1.825 | 1.136 | 3.679 | 0.754 | 52.3 |

| 800PJ350-68 | 1.179 | 12.165 | 3.041 | 3.212 | 1.99 | 1.299 | 11.749 | 2.406 | 72.03 | 65.37 | 4,219 | 3,368 | 1.998 | 25.787 | -2.733 | 1.648 | 4.413 | 0.616 | 70.5 |

| 800PJ350-97 | 1.671 | 17.065 | 4.266 | 3.195 | 2.782 | 1.29 | 16.927 | 3.711 | 111.11 | 107.52 | 10,885 | 6,032 | 5.762 | 36.082 | -2.717 | 1.64 | 4.388 | 0.617 | 70.7 |

| 800PJ350-118 | 2.029 | 20.553 | 5.138 | 3.183 | 3.341 | 1.283 | 20.553 | 4.87 | 145.82 | 140.85 | 16,235 | 7,312 | 10.398 | 43.367 | -2.705 | 1.633 | 4.37 | 0.617 | 70.9 |

| 1000PJ250-431 | 0.75 | 10.814 | 2.163 | 3.798 | 0.611 | 0.903 | 10.814 | 1.532 | 45.86 | 40.54 | 842 | 842 | 0.508 | 12.166 | -1.696 | 1.072 | 4.257 | 0.841 | 51.5 |

| 1000PJ250-54 | 0.939 | 13.49 | 2.698 | 3.791 | 0.76 | 0.9 | 13.49 | 2.106 | 63.06 | 56.25 | 1,668 | 1,668 | 1.002 | 15.121 | -1.69 | 1.068 | 4.247 | 0.842 | 51.4 |

| 1000PJ250-68 | 1.179 | 16.864 | 3.373 | 3.782 | 0.945 | 0.895 | 16.864 | 3.055 | 91.46 | 78.17 | 3,344 | 3,344 | 1.998 | 18.812 | -1.682 | 1.064 | 4.235 | 0.842 | 51.3 |

| 1000PJ250-973 | 1.671 | 23.674 | 4.735 | 3.764 | 1.312 | 0.886 | 23.674 | 4.649 | 155.43 | 138.05 | 9,766 | 7,190 | 5.762 | 26.138 | -1.666 | 1.055 | 4.21 | 0.843 | 51.2 |

| 1000PJ250-1183 | 2.029 | 28.529 | 5.706 | 3.75 | 1.568 | 0.879 | 28.529 | 5.706 | 194.34 | 183.17 | 16,235 | 9,733 | 10.398 | 31.25 | -1.653 | 1.048 | 4.192 | 0.844 | 51.1 |

| 1000PJ350-68 | 1.321 | 20.378 | 4.076 | 3.927 | 2.14 | 1.273 | 19.895 | 3.095 | 92.66 | 83.08 | 3,344 | 3,344 | 2.239 | 41.705 | -2.513 | 1.545 | 4.833 | 0.73 | 69.9 |

| 1000PJ350-97 | 1.875 | 28.656 | 5.731 | 3.91 | 2.993 | 1.263 | 28.567 | 5.03 | 150.59 | 138.04 | 9,766 | 7,190 | 6.463 | 58.323 | -2.497 | 1.536 | 4.808 | 0.73 | 69.9 |

| 1000PJ350-118 | 2.277 | 34.576 | 6.915 | 3.897 | 3.595 | 1.257 | 34.576 | 6.57 | 196.71 | 182.15 | 16,235 | 9,733 | 11.669 | 70.072 | -2.485 | 1.53 | 4.79 | 0.731 | 69.9 |

| 1200PJ250-541 | 1.052 | 20.909 | 3.485 | 4.459 | 0.799 | 0.871 | 19.92 | 2.417 | 72.37 | 67.25 | 1,382 | 1,382 | 1.123 | 22.624 | -1.55 | 0.995 | 4.8 | 0.896 | 50.6 |

| 1200PJ250-68 | 1.321 | 26.162 | 4.36 | 4.449 | 0.993 | 0.867 | 25.4 | 3.342 | 100.05 | 94.15 | 2,770 | 2,770 | 2.239 | 28.143 | -1.542 | 0.991 | 4.788 | 0.896 | 50.5 |

| 1200PJ250-97 | 1.875 | 36.799 | 6.133 | 4.43 | 1.379 | 0.858 | 36.661 | 5.692 | 170.41 | 156.46 | 8,080 | 7,420 | 6.463 | 39.093 | -1.526 | 0.981 | 4.764 | 0.897 | 50.3 |

| 1200PJ250-118 | 2.277 | 44.407 | 7.401 | 4.416 | 1.649 | 0.851 | 44.407 | 7.192 | 215.32 | 206.07 | 14,774 | 11,060 | 11.669 | 46.73 | -1.514 | 0.974 | 4.746 | 0.898 | 50.2 |

| 1200PJ350-68 | 1.464 | 31.235 | 5.206 | 4.619 | 2.261 | 1.243 | 30.647 | 3.689 | 110.45 | 100.55 | 2,770 | 2,770 | 2.481 | 62.405 | -2.33 | 1.456 | 5.32 | 0.808 | 69.3 |

| 1200PJ350-97 | 2.078 | 43.997 | 7.333 | 4.601 | 3.162 | 1.234 | 43.997 | 6.488 | 194.25 | 168.62 | 8,080 | 7,420 | 7.165 | 87.257 | -2.314 | 1.447 | 5.296 | 0.809 | 69.2 |

| 1200PJ350-118 | 2.525 | 53.152 | 8.859 | 4.588 | 3.799 | 1.227 | 53.152 | 8.439 | 252.66 | 223.92 | 14,774 | 11,060 | 12.94 | 104.824 | -2.301 | 1.44 | 5.278 | 0.81 | 69.1 |

| 1400PJ250-541 | 1.165 | 30.431 | 4.347 | 5.111 | 0.83 | 0.844 | 28.394 | 2.847 | 85.24 | 77.15 | 1,180 | 1,180 | 1.244 | 31.939 | -1.433 | 0.932 | 5.375 | 0.929 | 49.9 |

| 1400PJ250-68 | 1.464 | 38.104 | 5.443 | 5.102 | 1.032 | 0.84 | 36.334 | 3.948 | 118.21 | 108.77 | 2,364 | 2,364 | 2.481 | 39.728 | -1.425 | 0.928 | 5.363 | 0.929 | 49.7 |

| 1400PJ250-97 | 2.078 | 53.672 | 7.667 | 5.082 | 1.434 | 0.831 | 52.784 | 6.793 | 203.38 | 183.22 | 6,891 | 6,891 | 7.165 | 55.181 | -1.41 | 0.918 | 5.339 | 0.93 | 49.5 |

| 1400PJ250-118 | 2.525 | 64.839 | 9.263 | 5.068 | 1.714 | 0.824 | 64.835 | 8.651 | 259.03 | 243.57 | 12,592 | 11,304 | 12.94 | 65.96 | -1.398 | 0.912 | 5.321 | 0.931 | 49.3 |

| 1400PJ350-68 | 1.607 | 45.02 | 6.431 | 5.293 | 2.36 | 1.212 | 44.368 | 4.287 | 128.34 | 117.37 | 2,364 | 2,364 | 2.723 | 88.183 | -2.174 | 1.378 | 5.85 | 0.862 | 68.7 |

| 1400PJ350-97 | 2.282 | 63.495 | 9.071 | 5.275 | 3.301 | 1.203 | 63.495 | 7.93 | 237.41 | 198.55 | 6,891 | 6,891 | 7.866 | 123.298 | -2.158 | 1.369 | 5.825 | 0.863 | 68.5 |

| 1400PJ350-118 | 2.773 | 76.777 | 10.968 | 5.262 | 3.967 | 1.196 | 76.777 | 10.475 | 313.63 | 265.25 | 12,592 | 11,304 | 14.211 | 148.12 | -2.146 | 1.362 | 5.807 | 0.863 | 68.4 |

| 1600PJ250-681 | 1.607 | 52.973 | 6.622 | 5.742 | 1.065 | 0.814 | 49.61 | 4.553 | 136.33 | 121.82 | 2,062 | 2,062 | 2.723 | 53.658 | -1.326 | 0.873 | 5.949 | 0.95 | 49 |

| 1600PJ250-97 | 2.282 | 74.702 | 9.338 | 5.722 | 1.478 | 0.805 | 72.453 | 7.893 | 236.32 | 207.81 | 6,007 | 6,007 | 7.866 | 74.527 | -1.311 | 0.864 | 5.925 | 0.951 | 48.7 |

| 1600PJ250-118 | 2.773 | 90.321 | 11.29 | 5.707 | 1.767 | 0.798 | 89.314 | 10.113 | 302.79 | 278.66 | 10,972 | 10,972 | 14.211 | 89.083 | -1.3 | 0.857 | 5.908 | 0.952 | 48.4 |

Notes:

- Web-height-to-thickness ratio exceeds 200. Web stiffeners are required at all support points and concentric loads. Suitability of web holes must be evaluated independently.

- When web-height-to thickness ratio exceeds 260, or flange-width-to-thickness ratio exceeds 60, effective properties are not calculated (limitations in AISI Section B1).

- Allowable moment includes cold-work of forming.

Follow us on Social Media