How do you ensure that your project’s cold-formed steel (CFS) framing has the right design?

Answer: You follow the code requirements. For complex commercial construction, you hire a professional engineer who understands proper design. Engineers can match the strength of the framing with the proper design loads and know what documents provide guidance on the overall process.

Module 3: “Engineering Requirements” of AWCI’s Steel—Doing It Right® describes the role of engineers — both structural engineers of record (SERs) and specialty structural engineers (SSEs) — and the engineering principles, design considerations and documents providing guidance related to the CFS framing design process.

Ability to resist loads

Buildings have multiple complex systems that must work together to meet the needs of the building owner and the occupants. CFS framing is only one part of one system, the structural system, but it’s integral that it be designed properly to work together with all other systems and components of a building.

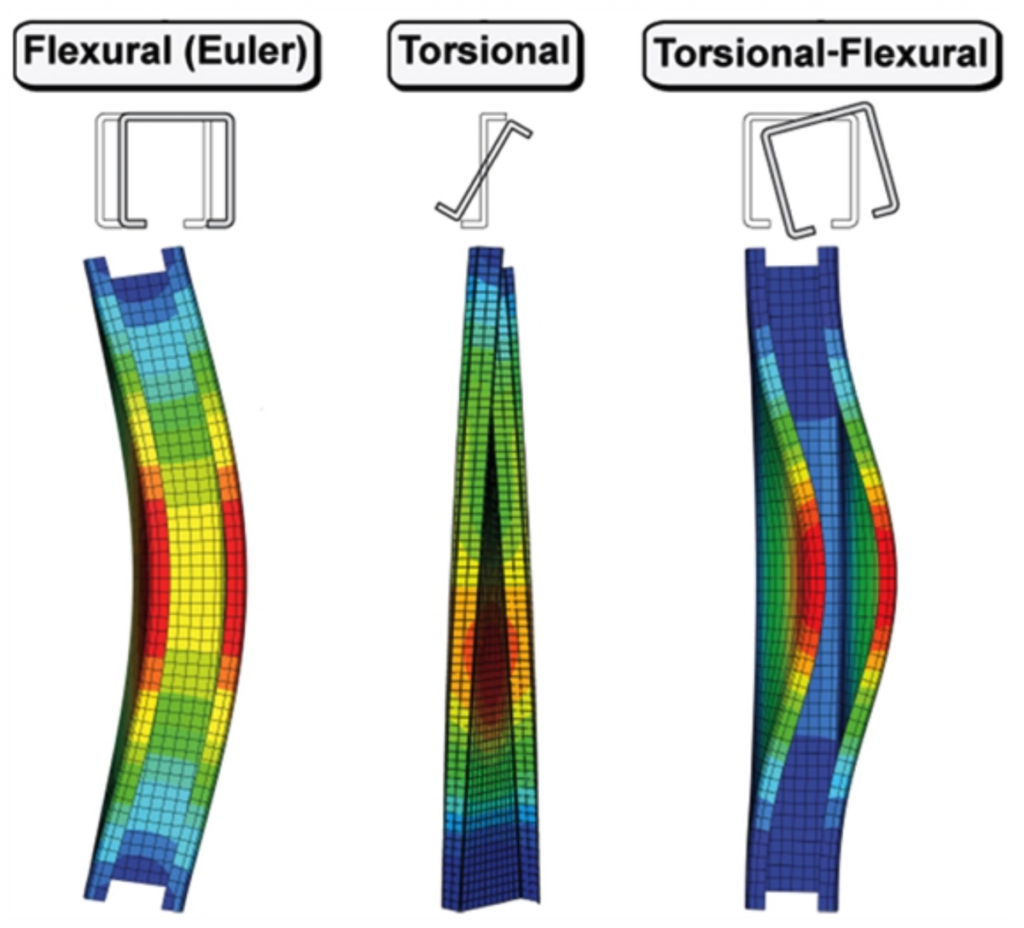

CFS framing follows different design principles than hot rolled steel. Here are some principles that relate to the ability of CFS framing systems to resist loads.

Bridging, Bracing and Blocking

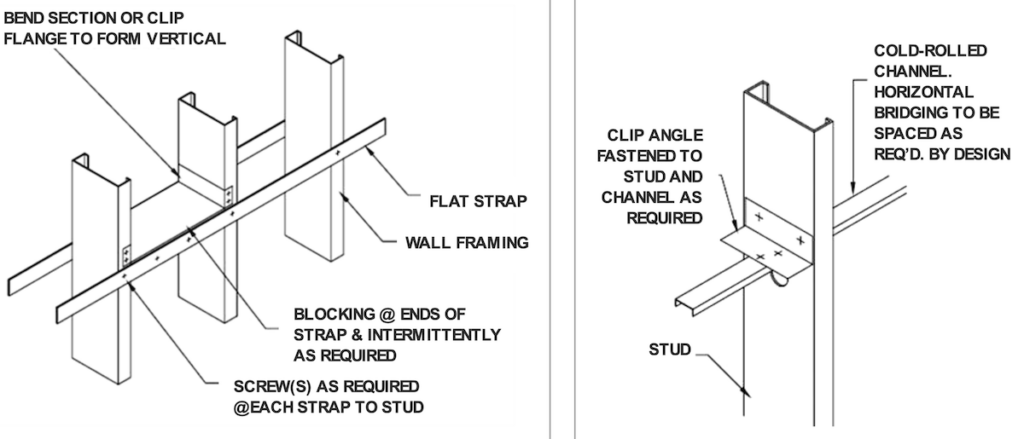

CFS strength is achieved by using bridging, bracing and blocking. These design considerations, which are not always part of the design of other structural materials, are why it’s important to hire an engineer with CFS experience and training.

Bracing, bridging and blocking are important to resist buckling. While this article won’t cover the engineering behind bracing, bridging and blocking, these diagrams show what they can involve:

Importance of Engineers

Structural engineer of record (SER) and the specialty structural engineer (SSE) are responsible for getting the right design to the contractor for installation.

- Structural engineer of record: The SER designs the primary structural system and oversees all aspects of the structural engineering

- Specialty structural engineer: The SER may delegate the design of certain specialty systems to an SSE who has the expertise and experience to perform a more detailed design of the systems

- Framing contractor: Any changes to the building structural support system made in the field must be approved by the SER before implementation

CFS Resources

When engineers do not have a formal education in CFS design, resources from various organizations can be helpful.

- The Cold-Formed Steel Engineers Institute (CFSEI) has educational materials and an annual conference that can help bring engineers up to speed

- The Steel Framing Industry Association (SFIA) has a variety of educational programs and technical publications for engineers, contractors, building owners and others

Framing Contractors

Framing contractors need to accurately bid their work. The framing contractor may want to hire an engineer who is ordinarily an SER to design the CFS framing. But because very few undergraduate engineering programs offer training in CFS design, some engineers may not have the training necessary to develop a complete and easy to build CFS framing design. If this is the case, the SER may delegate the CFS design to an SSE.

This delegated design usually comes under the scope of the framing contractor. This requirement is most often in Section 54000 of the specification or in the structural general notes. But sometimes it is hidden in the CFS details or in another section of the specifications.

- Check your contract documents carefully

- Don’t take on this responsibility yourself unless you have the proper training with CFS design

Develop a relationship with a specialty structural engineer with CFS experience before you bid projects. This way you can minimize the risk of submitting a bid based on the wrong thickness of steel or the wrong type of material.

Article cited from BuildSteel