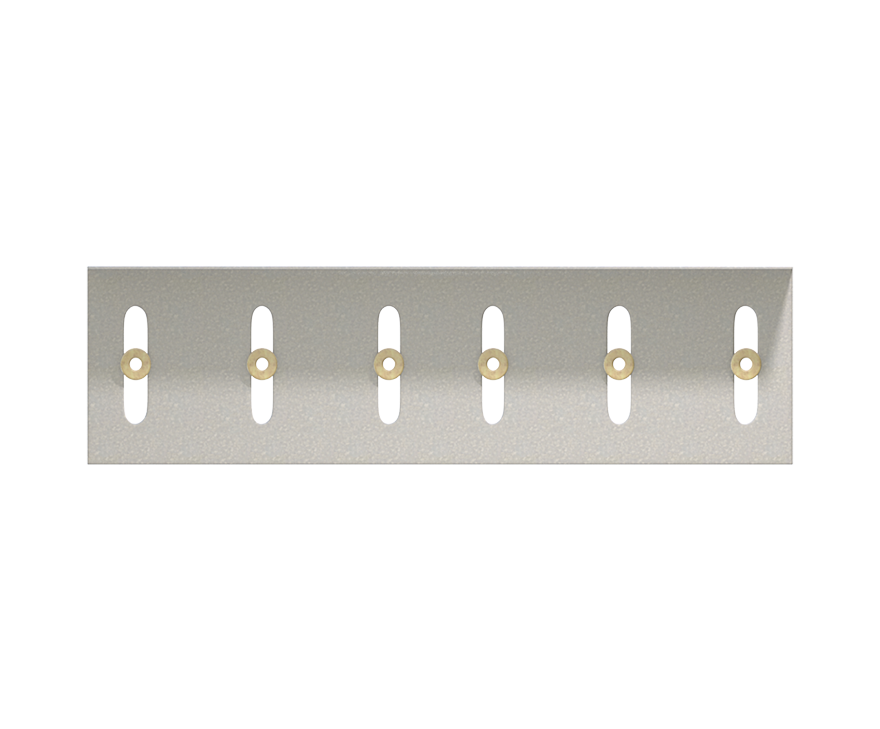

VertiClip® SLS

This vertical deflection strut is used to connect exterior cold-formed steel curtain wall studs to structural steel frame when large stand-off conditions exist, bypassing the primary structure, while allowing for a vertical deflection of the structure up to 1 ½” (¾” up and ¾” down). TSN’s patented Step Bushing Technology® provides an anti-friction and anti-seizure connection between the clip and the stud web surface.

Features

- Variety of lengths available

- ICC-ES Approved, report #ESR-2049

- LARR Approved, report #25631

- Load-rated positive mechanical attachment at each stud

- Patented Step Bushing Technology® provides friction-free motion for smooth vertical deflection

- Eliminates loose friction-held assemblies, heavy deep-leg track, & top row of wall bridging/strapping

- Load-rated #12 screws provided for vertical deflection connection to stud web

- Manufactured with certified, 50ksi, 68mil, G90 cold-formed steel

Material Composition

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. VertiClip® SLS can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

US Patents #5,467,566 & #5,906,080

Order Information

Qty/Box

SLS362/400-9*

SLS362/400-12*

SLS600-12

SLS600-15

SLS600-18

SLS600-20

SLS600-24

SLS600-30

SLS600-36

SLS800-12

SLS800-15

SLS800-18

SLS800-20

Lbs/Box

SLS362/400-9*

SLS362/400-12*

SLS600-12

SLS600-15

SLS600-18

SLS600-20

SLS600-24

SLS600-30

SLS600-36

SLS800-12

SLS800-15

SLS800-18

SLS800-20

Qty/Skid

SLS362/400-9*

SLS362/400-12*

SLS600-12

SLS600-15

SLS600-18

SLS600-20

SLS600-24

SLS600-30

SLS600-36

SLS800-12

SLS800-15

SLS800-18

SLS800-20

Lbs/Skid

SLS362/400-9*

SLS362/400-12*

SLS600-12

SLS600-15

SLS600-18

SLS600-20

SLS600-24

SLS600-30

SLS600-36

SLS800-12

SLS800-15

SLS800-18

SLS800-20

Nomeclature

VertiClip SLS is designated by stud depth and clip length required. Clip length includes a minimum of 3″ for steel (5.5″ for concrete) of clip material for attachment to structure added to stud depth, plus the distance of the stud from the structure.

Example:6″ stud, 6″ tolerance, 3″ to structure

Designate:VertiClip® SLS600-15

* Use of strengthening ribs and return bends varies with each clip.

VertiClip SLS Downloads

VertiClip® SLS Applications

The attachment of VertiClip SLS to the primary structure may be made with PAFs, screw/bolt anchors or weld and is dependent upon the base material (steel or concrete) and the design configuration.

Steel Frame Bypass

Installation Instructions

- Attach SLS to structure with engineered attachment. Allow recommended minimum clip area for attachment.

- Align studs to SLS for plumb wall assembly.

- Fasten SLS to wall stud with provided screws through Step Bushings

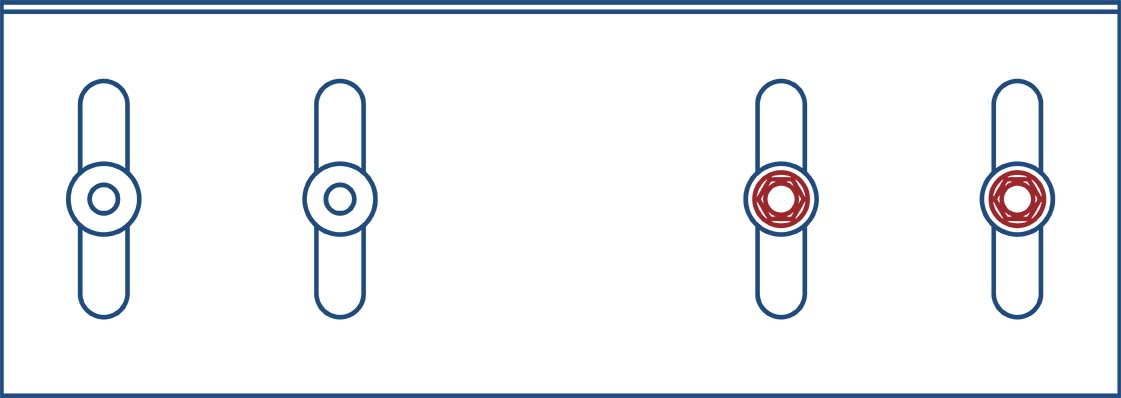

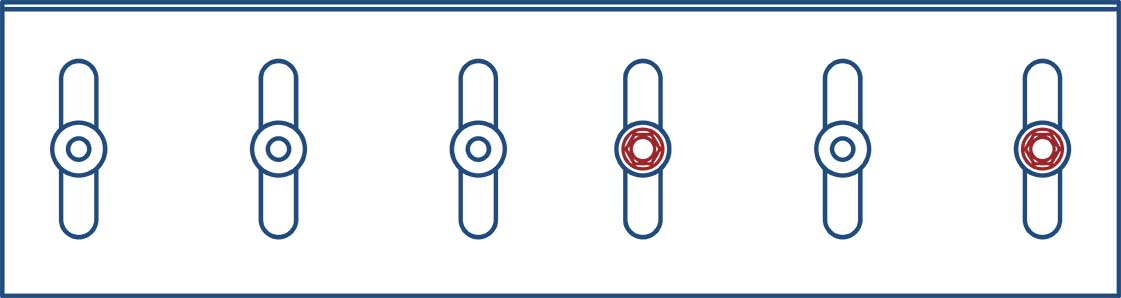

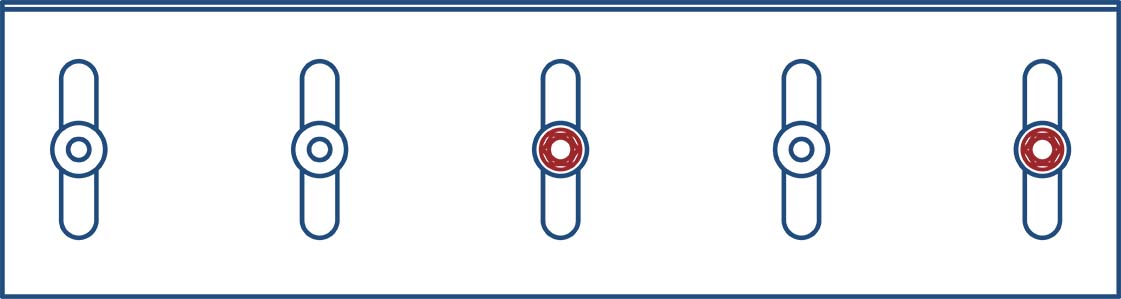

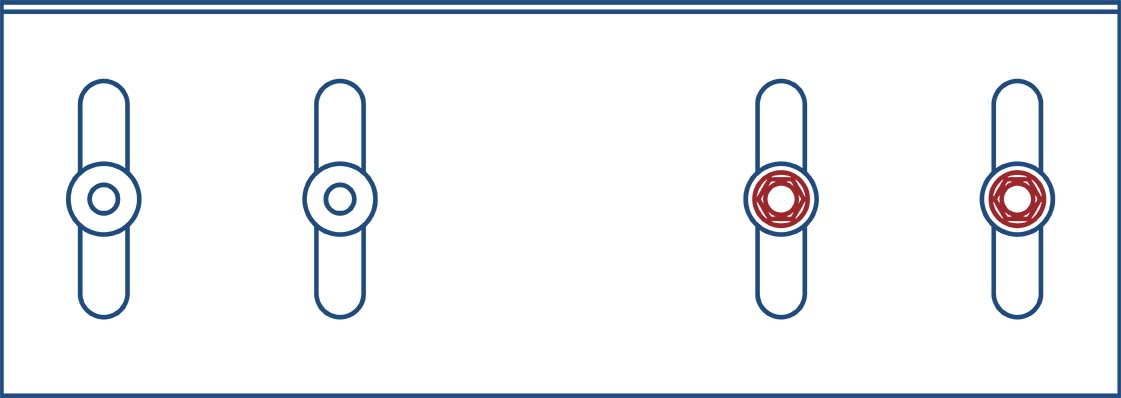

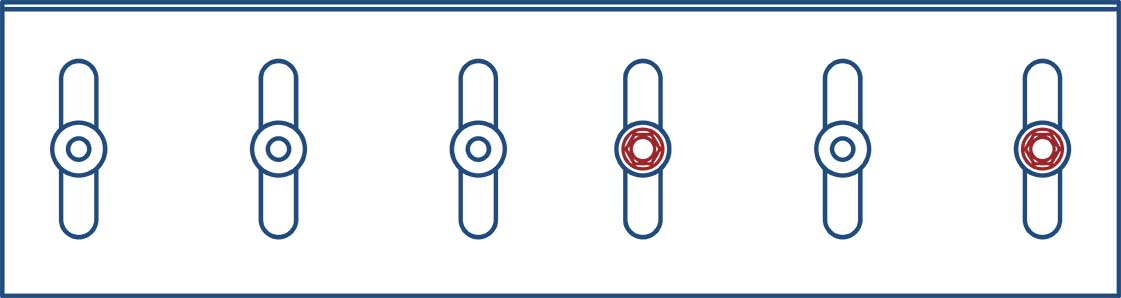

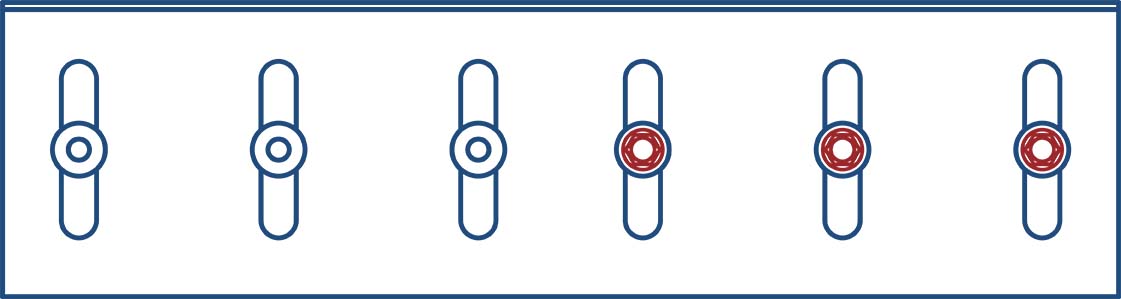

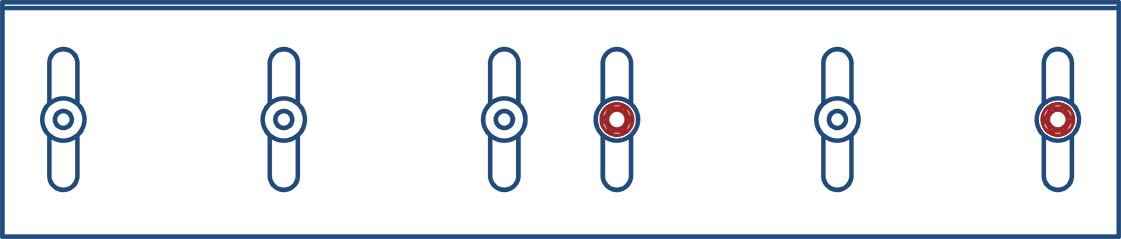

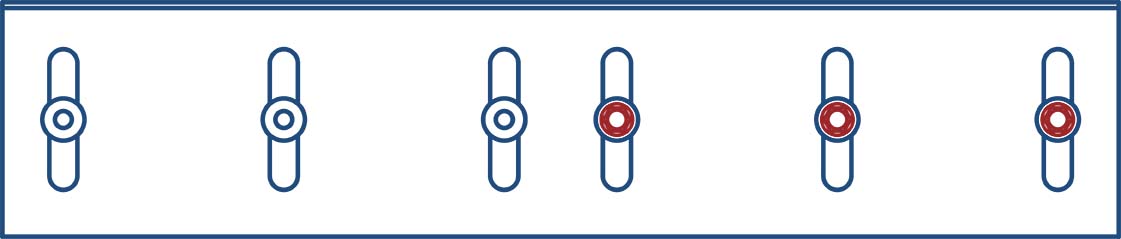

This Connector Features Step Bushing Technology!

Step Bushing Technology is transforming the performance of deflection clips. Designed for optimal movement and reliability, Step Bushings eliminate the need for costly, specialized shoulder screws and the tedious adjustments they require. Instead, they deliver friction-free connections that enable smooth, consistent deflection and exceptional performance.

See the Difference

Watch the video for a side-by-side comparison of a clip deflecting with Step Bushings versus a generic clip using specialized screws. Step Bushing Technology is more than an innovation—it’s a game-changer for efficiency, durability, and simplicity on the job site.

Allowable Loads

w/2 #12 Screws

w/2 or 3 #12 Screws

w/2 or 3 #12 Screws

w/2 or 3 #12 Screws

w/2 or 3 #12 Screws

w/2 or 3 #12 Screws

w/2 #12 Screws

w/2 #12 Screws

w/3 #12 Screws

w/2 #12 Screws

w/3 #12 Screws

w/2 #12 Screws

w/3 #12 Screws

w/2 #12 Screws

w/3 #12 Screws

Notes:

- VertiClip SLS is designed to support horizontal loads, and should not be used in axial load-bearing walls.

- Allowable loads have not been increased for wind, seismic, or other factors.

- Return lip added for clips longer than 20″.

- #12 screws are provided with each step bushing for attachment to the stud web.

- Minimum 3″ of SLS required for attachment to steel structure and minimum 5-1/2″ for attachment to concrete structure.

- Fasten within 3/4″ of the angle heel (centerline of the 1-1/2″ leg) to minimize eccentric load transfer.

- Total vertical deflection of up to 1-1/2″ (3/4″ up and 3/4″ down). Deflection requirements greater than 3/4″ (up and down) are available.

- Allowable load tables incorporate eccentric loading of fasteners. Values with welded connection may increase.

- For LRFD strengths contact TSN technical services.

Load Direction

Follow us on Social Media