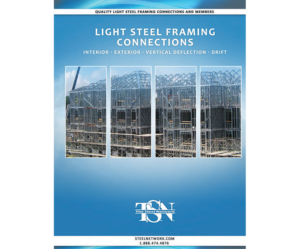

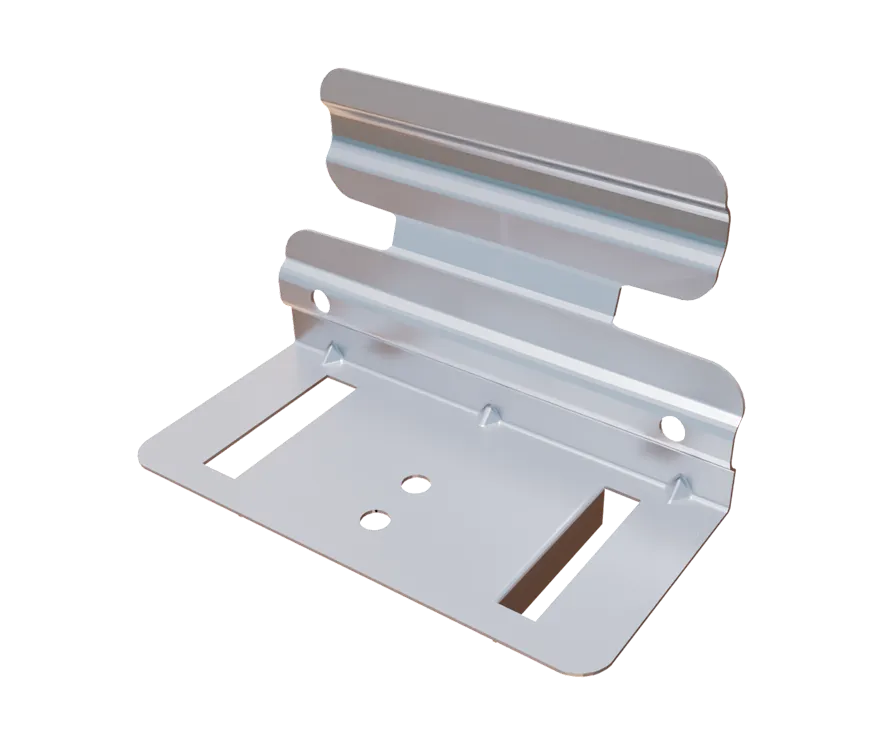

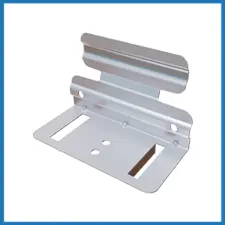

BridgeClip® Bridging Channel Clip

Features

- Fast installation

- No clamping

- No welding

- Guide holes provided for quick and accurate fastener placement

- Rounded edges for safety

- Laborers are working on installation, not cutting angle

- Certified, 50ksi steel, G90 galvanized coating

- 33 Mil thickness (BC-33)

- 43 Mil thickness (BC-43, BC600 & BC800)

Material Composition

BC-33: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 33mil minimum thickness (20 gauge, 0.0346″ design thickness) with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating.

BC-43, BC600 & BC800: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 43mil minimum thickness (18 gauge, 0.0451″ design thickness) with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating.

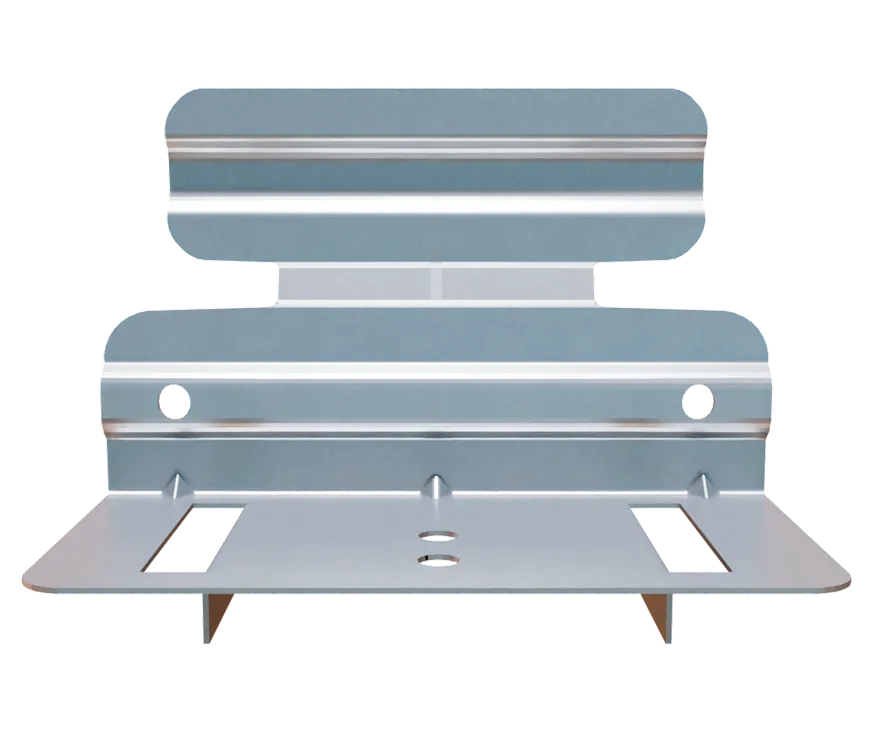

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. BridgeClip® can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

US Patents #5,904,023

BridgeClip® is engineered for fast, positive attachment at each stud, ensuring code compliance and labor savings. For complete load tables and engineering guidelines, see our Cold-Formed Steel Bridging Design Requirements.

Order Information

Nomenclature

BridgeClip is available in 3⅝”, 6″ and 8″ and is designated by the type, BC. Designations are BC-33, BC-43, BC600 & BC800.

Example: 6″ Stud

Designate: BC600

BridgeClip Downloads

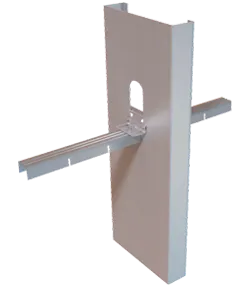

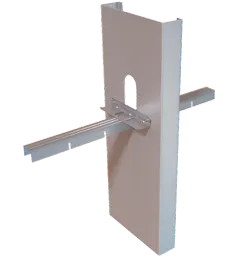

BridgeClip® Applications

BridgeClip for 3" & 4" Studs

BridgeClip for 6" & 8" Studs

Installation Instructions

Allowable Loads

Table Nomenclature:

Notes:

- Listed ASD allowable loads are based on ultimate test data divided by a factor of safety.

- Listed ASD allowable loads are limited by screw shear or pullout at stud web.

Load Direction

Follow us on Social Media