DriftTrak® for Head of Wall

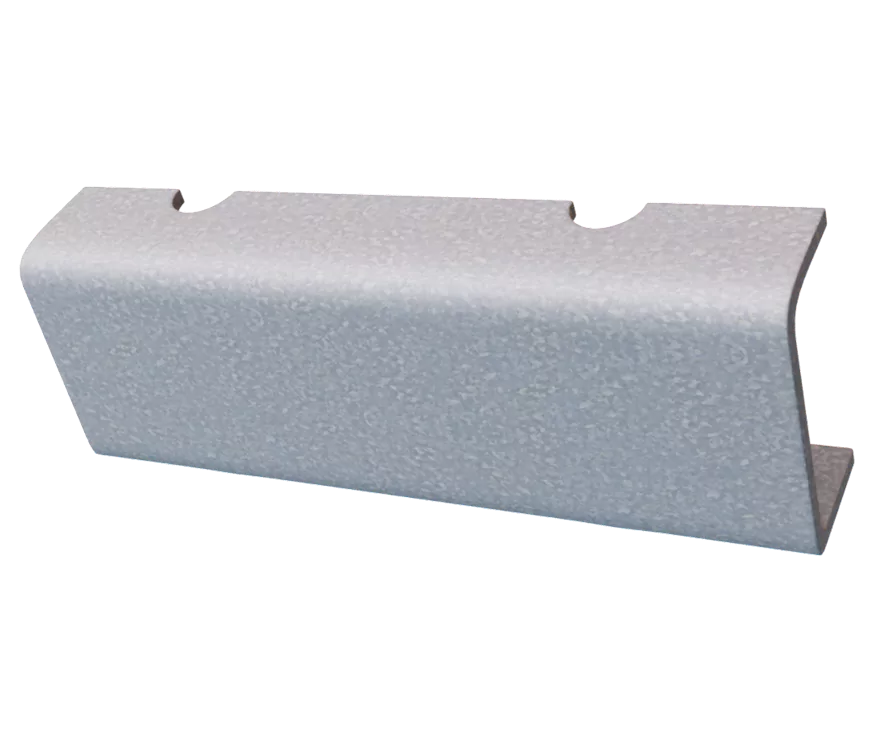

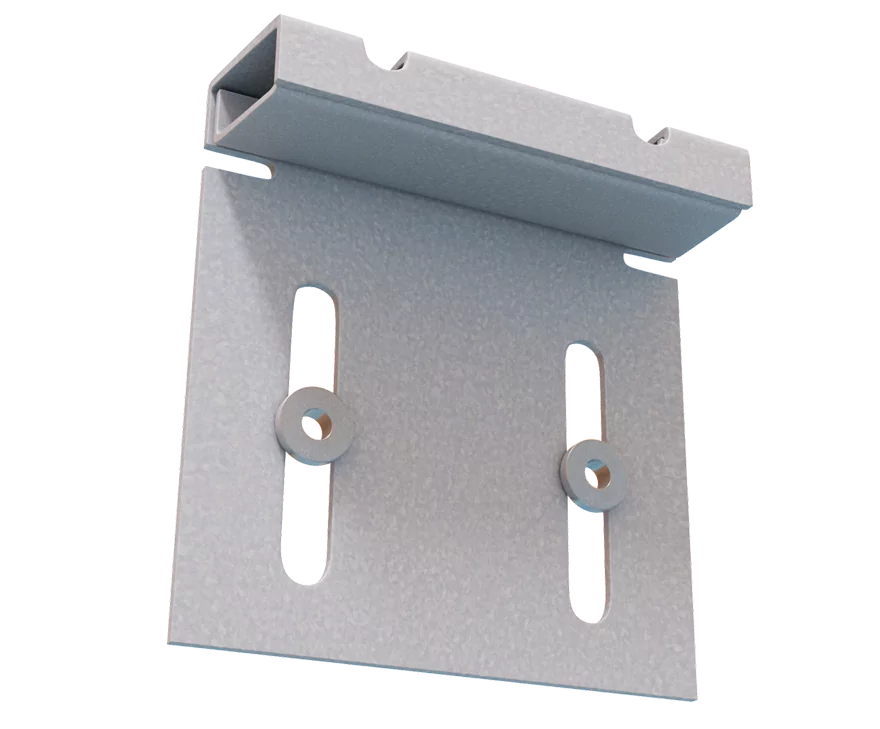

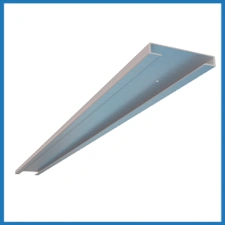

This drift slide track incorporates the DriftTrak member with the DriftTrak DTSL slide angle and is used to connect exterior cold-formed steel curtain wall studs to the primary structure at the head of wall, while allowing for up to 2” vertical deflection (1” up and down) and free lateral drift within the DrifTrak. TSN’s patented Step Bushing Technology® provides an anti-friction and anti-seizure connection between the clip and both the stud web surface & track.

Features

- ICC-ES Approved, report #ESR-2049

- Grooves in 1” leg pass over fastener heads

- DriftTrak is available in 12’ lengths.

- DriftTrak does not provide wall closure. A top track will be required for closure of the wall assembly.

- Load-rated positive mechanical attachment at each stud

- Patented Step Bushing Technology® provides friction-free motion for smooth vertical deflection

- Eliminates loose friction-held assemblies, heavy deep-leg track, & top row of wall bridging/strapping

- Load-rated #12 screws provided for vertical deflection connection to stud web

- Track manufactured with certified, 50ksi, 97mil, G90 cold-formed steel

- Clip manufactured with certified, 50ksi, 68mil, G90 cold-formed steel

Material Composition

Clip Material: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 68mil minimum thickness (14 gauge, 0.0713” design thickness) with ASTM A653/A653M G90 (Z275) hot dipped galvanized coating.

Track Material: ASTM A1003/A1003M Structural Grade 50 (340) Type H, ST50H (ST340H): 50ksi (340MPa) minimum yield strength, 65ksi (450MPa) minimum tensile strength, 97mil minimum thickness (12 gauge, 0.1017” design thickness) with ASTM A653/A653M G60 (Z180) hot dipped galvanized coating.

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. DriftTrak® Head of Wall can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

Order Information

Nomenclature

DT-12ft & DTSL is available in one size for all stud depths over 3 ⅝”.

Example:6″ stud depth

Designate: DT-12ft & DTSL

* A top track is required for closure of the wall assembly.

** Clips and track sold separately.

DriftTrak® Head of Wall Downloads

DriftTrak® Head of Wall Applications

The attachment of DriftTrak DTSL to the primary structure utilizes step bushings designed for #8 (0.164″) screws. Designing this connection is the responsibility of the Structural Engineer of Record, and a minimum of two fasteners must be used.

Drywall Head of Wall Drift Track Connection

Installation Instructions

- Fit DriftTrak into top track and secure to deck with approved fastener.

- Twist clip into place within DriftTrak. Ensure stiffener is in place prior to installation.

- Fasten to stud using provided screws through Step Bushings.

Note: Allow a minimum of 0.875” from the structure to the top of the stud to allow for the attachment of DriftTrak inside the standard track.

DriftTrak® Head of Wall:

Load Table Notes:

- Design loads are for attachment of DriftTrak DT w/ DTSL to stud only.

- Allowable loads have not been increased for wind, seismic, or other factors.

- Clips are manufactured to fit into DriftTrak DT. DriftTrak DT w/ DTSL allows up to 2″ of vertical deflection (1″ up and 1″ down), and free lateral movement of the structure.

- #12 screws are provided for each step bushing attachment to studs.

- Attachment of structure to be engineered by others.

- One row of bridging is recommended at a maximum distance of 18″ from DriftTrak DT w/ DTSL to resist torsional effects.

- DriftTrak DT w/ DTSL does not provide wall closure. A top track will be required for closure of the wall assembly.

- Allow a minimum of 7/8″ from the structure to the top of the stud to allow for the attachment of the DriftTrak DT inside the standard track.

- For LRFD strengths contact TSN technical services.

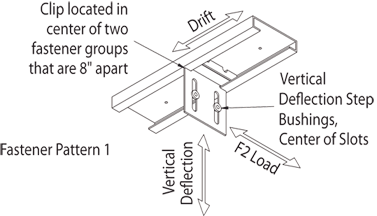

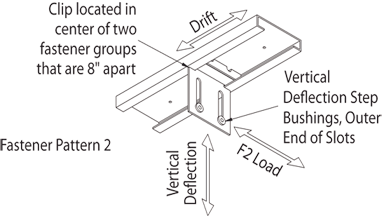

Load Direction

F2 Load Directions

Screw Pattern 1

Screw Pattern 2

Follow us on Social Media