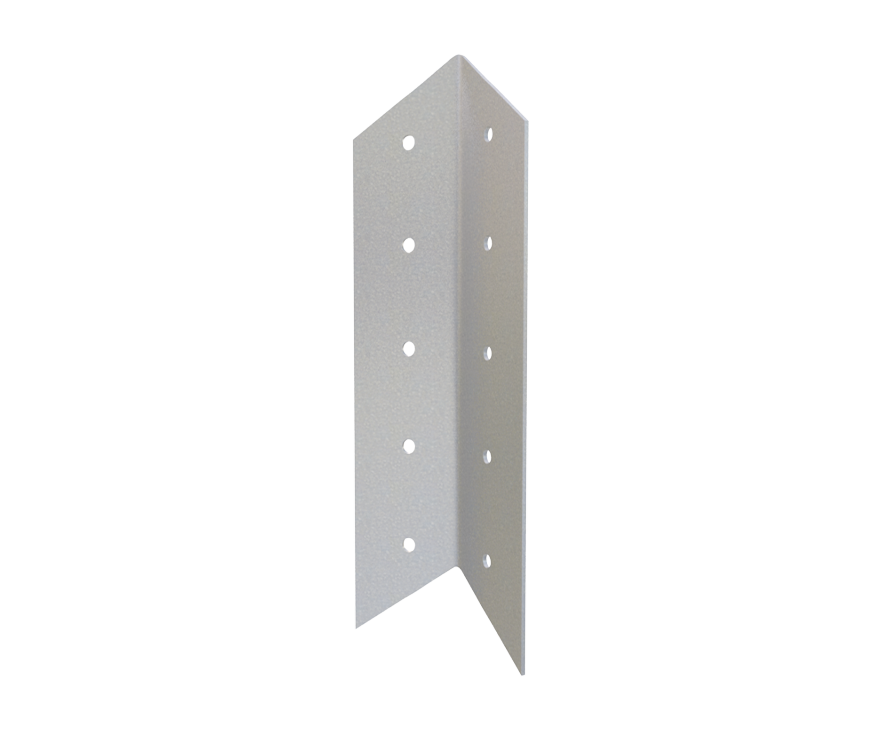

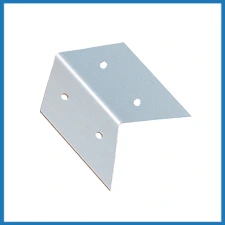

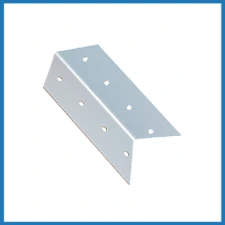

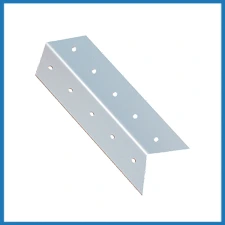

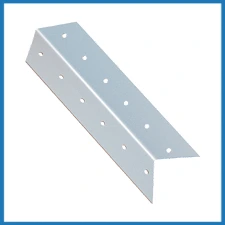

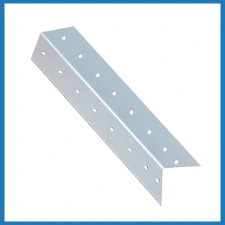

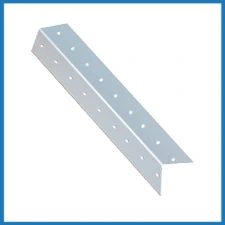

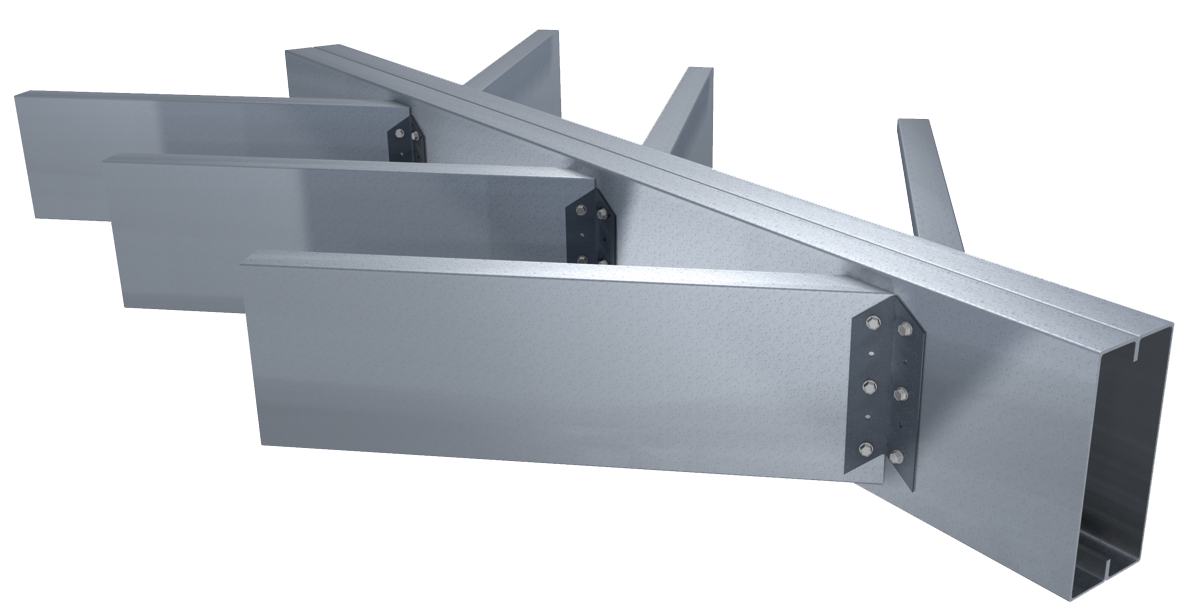

StiffClip® HC Hip Connector

Features

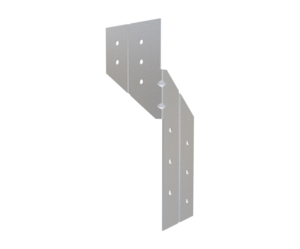

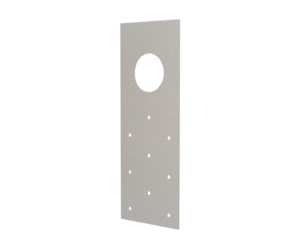

- Guide holes for attachment to framing members (.172” in diameter)

- Engineered for steel members

- Structurally load tested

- Meets all building code criteria

Material Composition

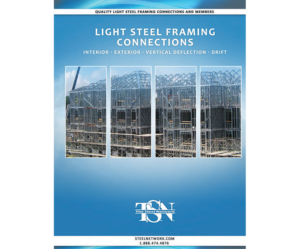

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. StiffClip® HC can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

Order Information

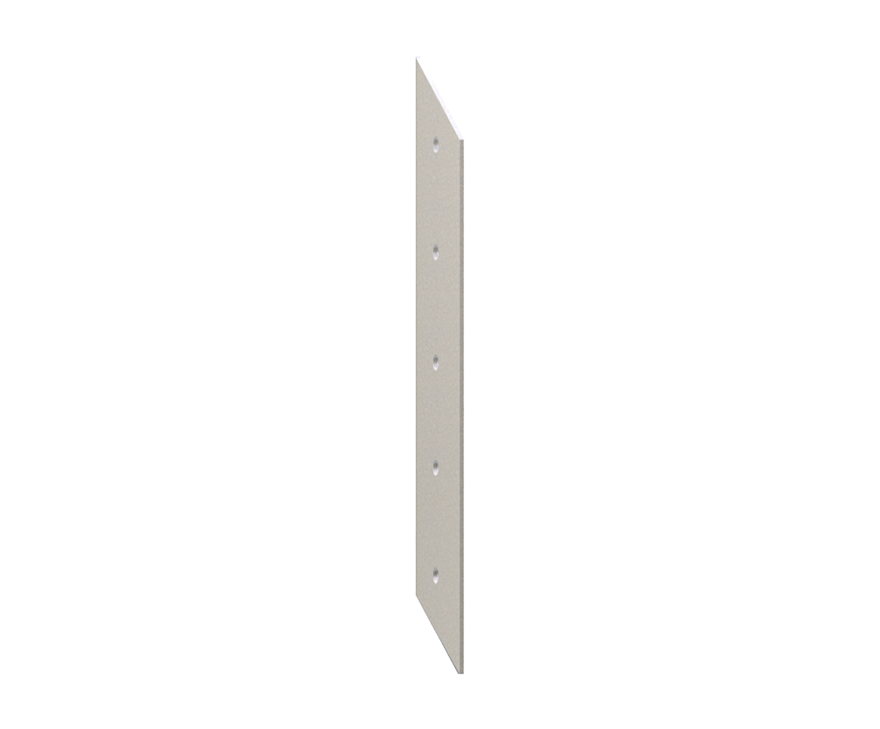

Nomenclature

StiffClip HC is designated by multiplying joist depth by 100, then listing material thickness.

Example: 6″ stud depth, 68mil steel thickness

Designate: StiffClip® HC600-68

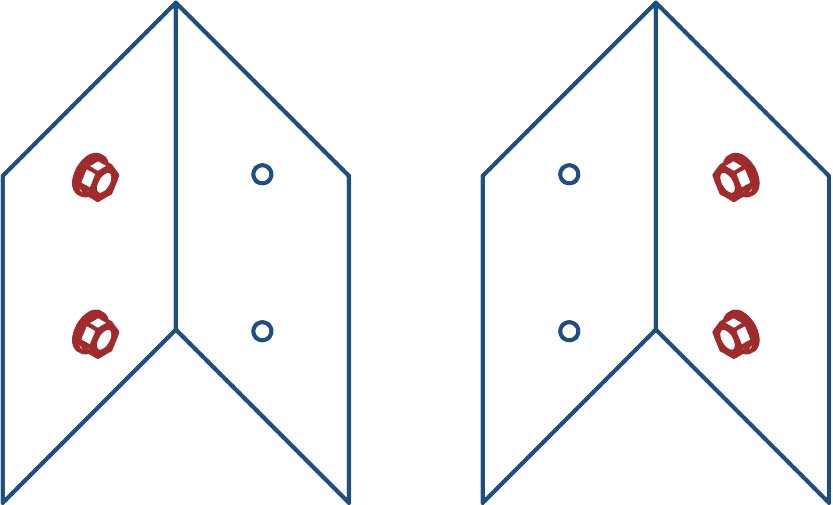

* Standard angle bend is 135°. Other angle shapes are available.

StiffClip® HC Downloads

StiffClip® HC Applications

The unique design of MasterClip allows it to be installed either as a vertical deflection connection or a rigid connection. Attachment to the primary structure may be made with a PAF, screw/bolt anchors, or weld and is dependent upon the base material (steel or concrete) and the design configuration.

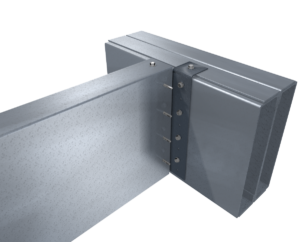

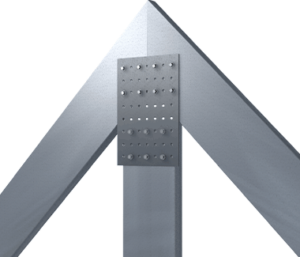

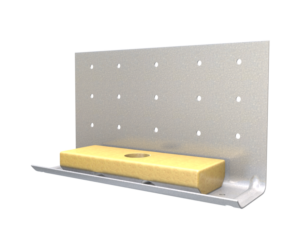

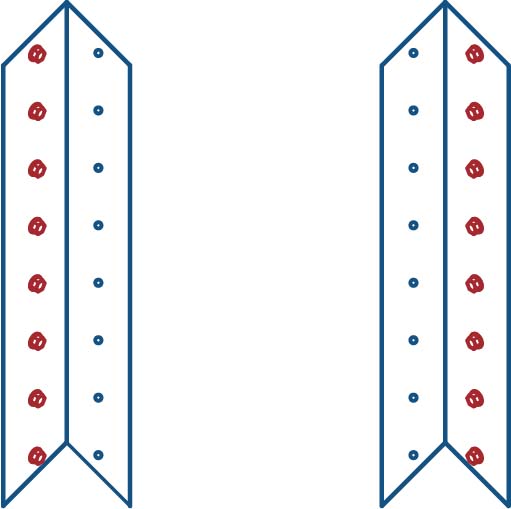

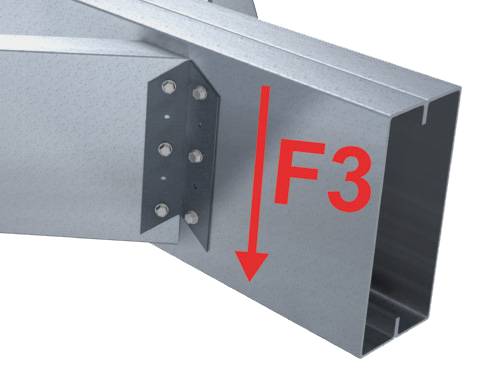

Roof Joist Hip Connection

Installation Instructions

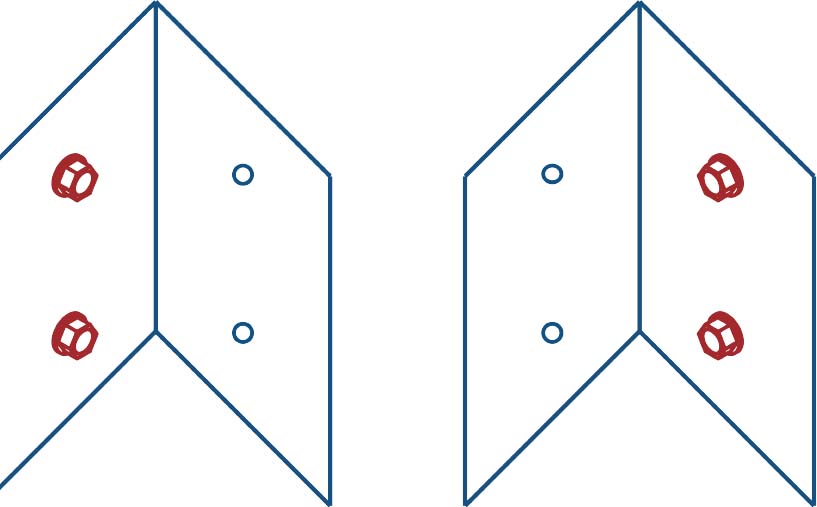

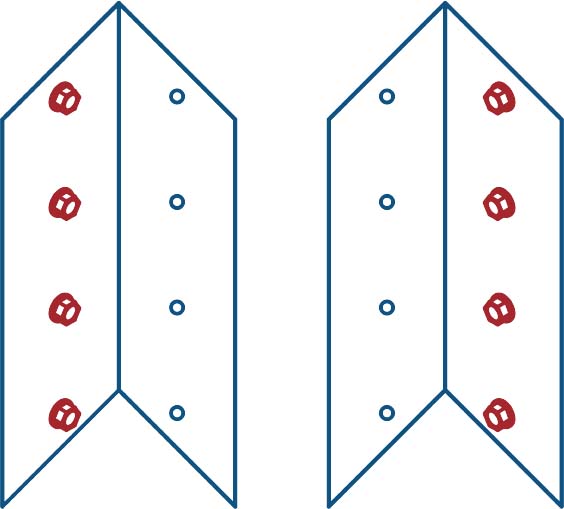

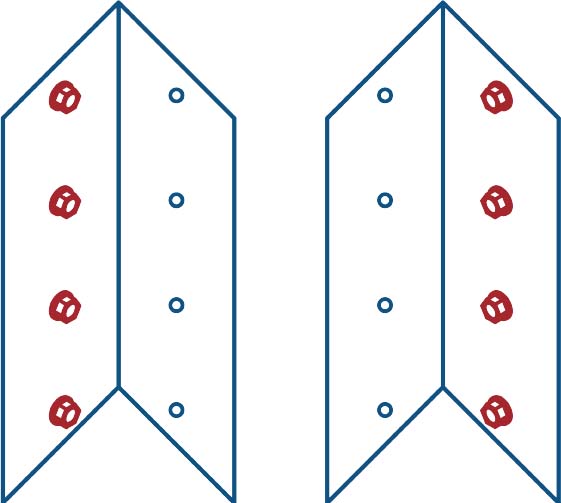

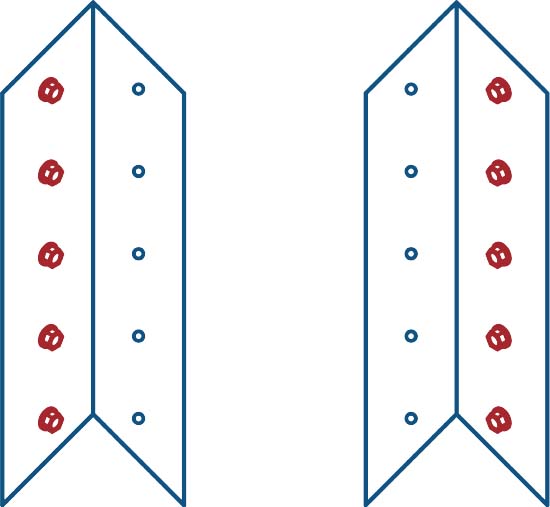

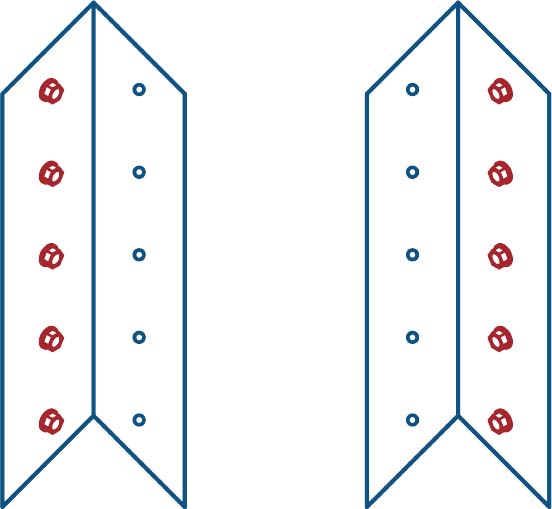

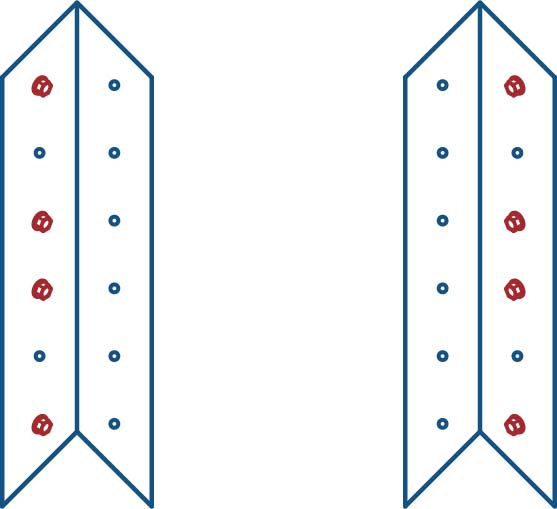

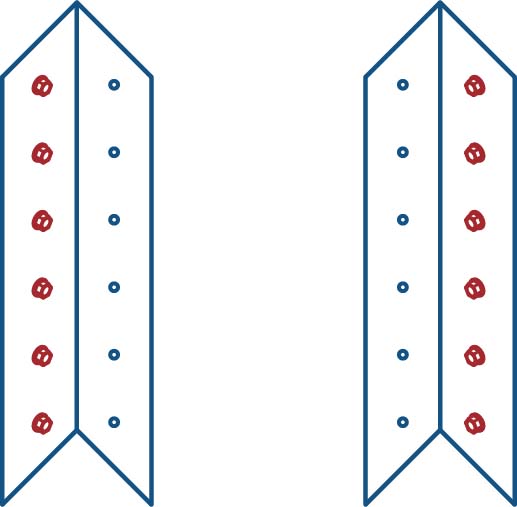

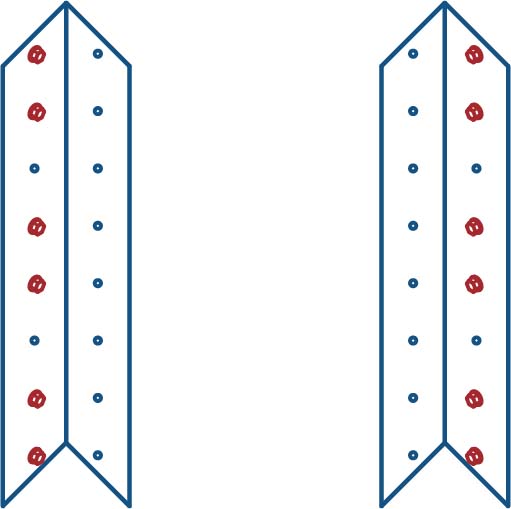

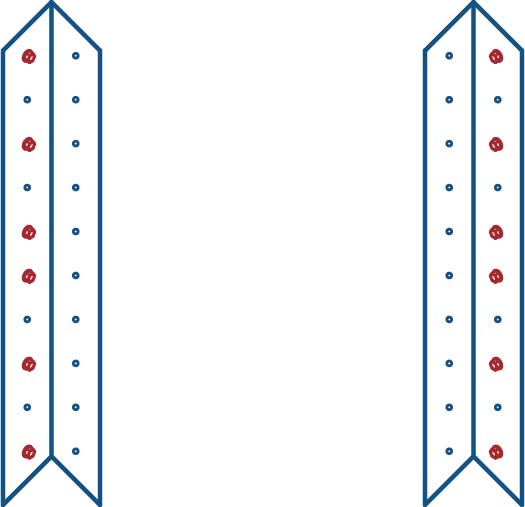

- Attach end of StiffClip HC to hip beam with required number of fasteners.

- Next, attach StiffClip HC to roof joist framing member with required number of screws.

Load Table Notes:

- Design loads are for attachment of StiffClip HC to cold formed framing only. Load tables reflect vertical loads (F3).

- Design loads consider loads on the clip and #12 screw fasteners in each leg.

- Torsional effects are considered on screw group for F3 allowable loads. It is assumed that half of the torsional moment is taken by screw group in each leg of clip .

- Allowable loads have not been increased for wind, seismic, or other factors.

- For LRFD strengths contact TSN technical services.

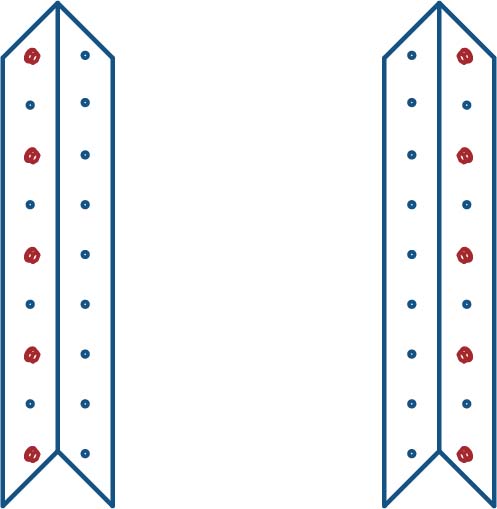

2 Screws

2 Screws 2 Screws

2 Screws 4 Screws

4 Screws 4 Screws

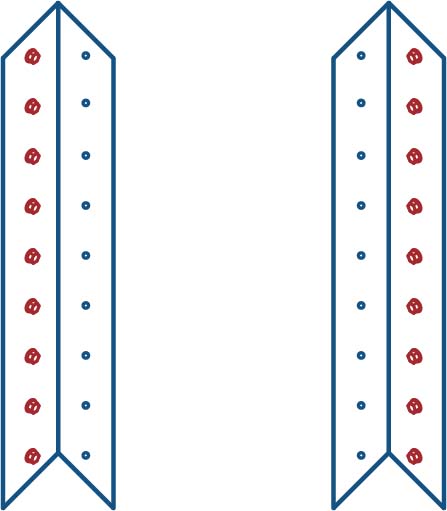

4 Screws 5 Screws

5 Screws 5 Screws

5 Screws 4 Screws

4 Screws 6 Screws

6 Screws 6 Screws

6 Screws 8 Screws

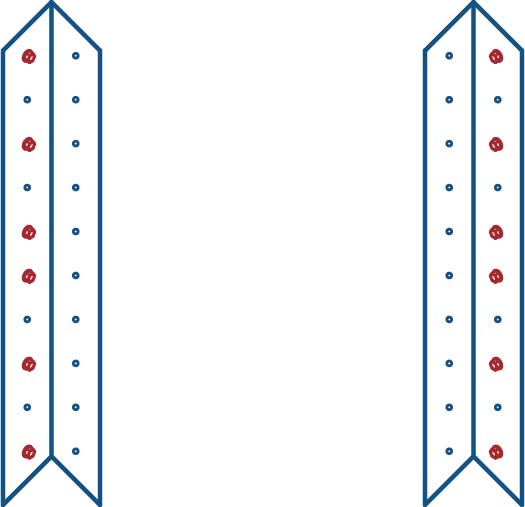

8 Screws 5 Screws

5 Screws 9 Screws

9 Screws 6 Screws

6 Screws 10 Screws

10 Screws

Load Direction

More Rigid Connectors

Follow us on Social Media