StiffClip® PLC

Features

- Safely lift and place assembled wall components

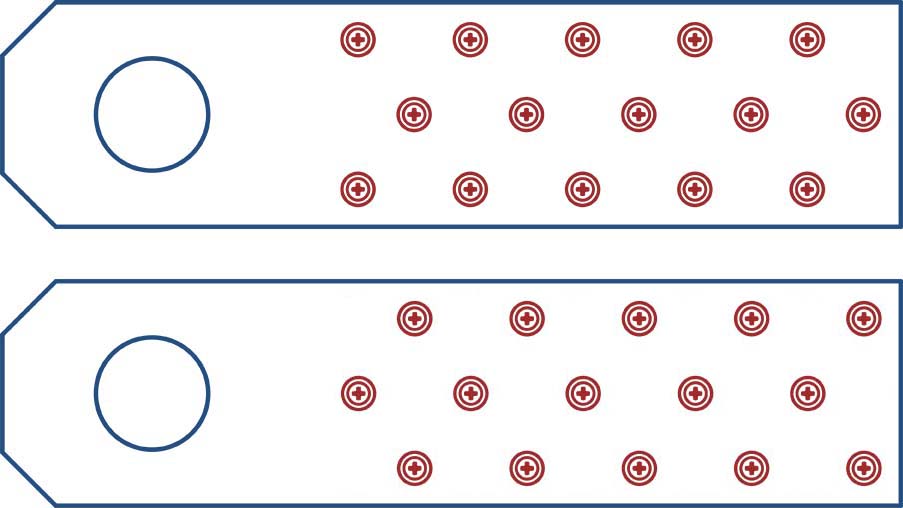

- Attaches easily through pre-punched guide holes

- Utilizes only certified, 50ksi steel

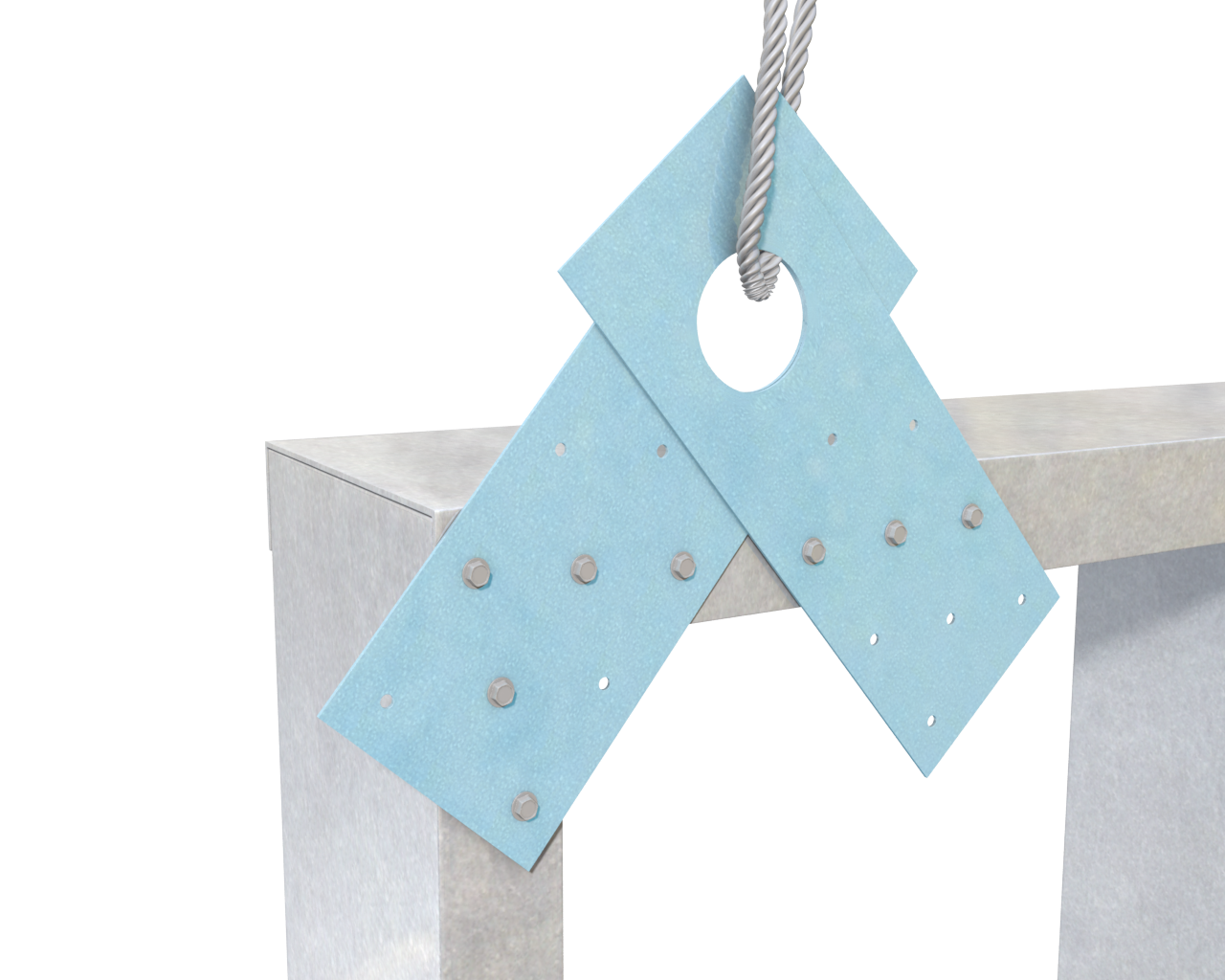

- Adaptable for multiple configurations

Material Composition

Catalogs

TSN’s Product Catalogs are an essential resource for the design of cold formed steel. Developed by Engineers, the catalogs contain design data for members, connectors, and fasteners. StiffClip® PLC can be found in the following Catalogs:

For a full list of our product catalogs, specification sections, inspection checklists, and research reports please click here.

Order Information

Nomenclature

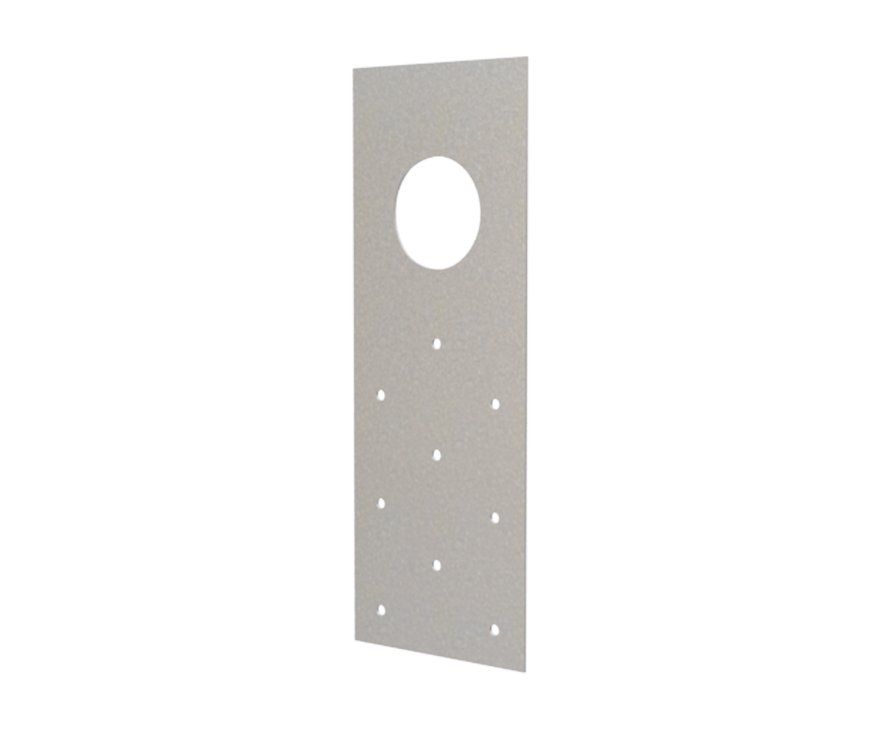

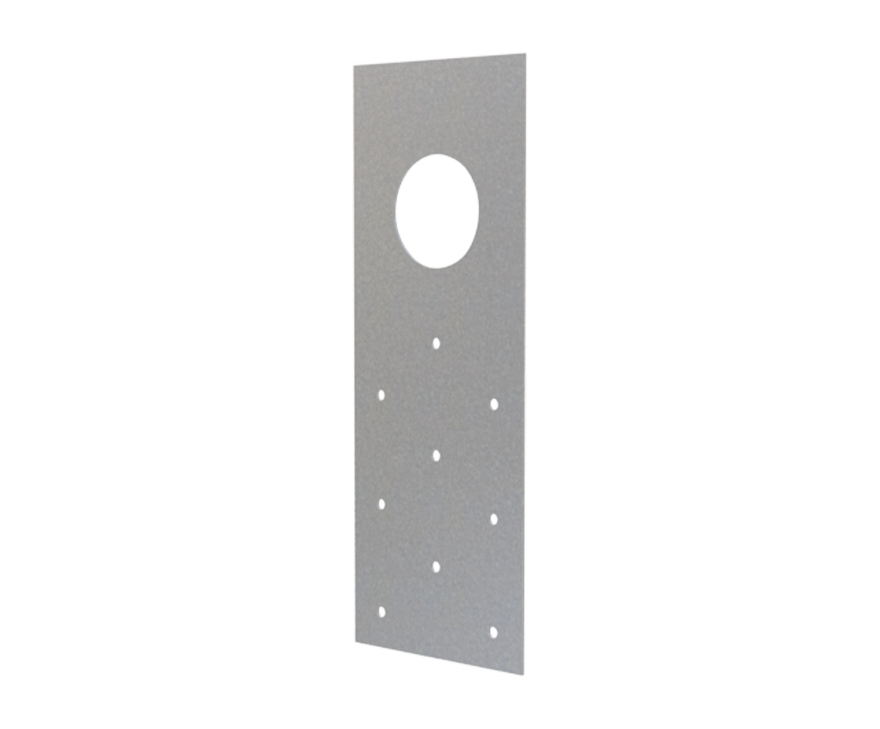

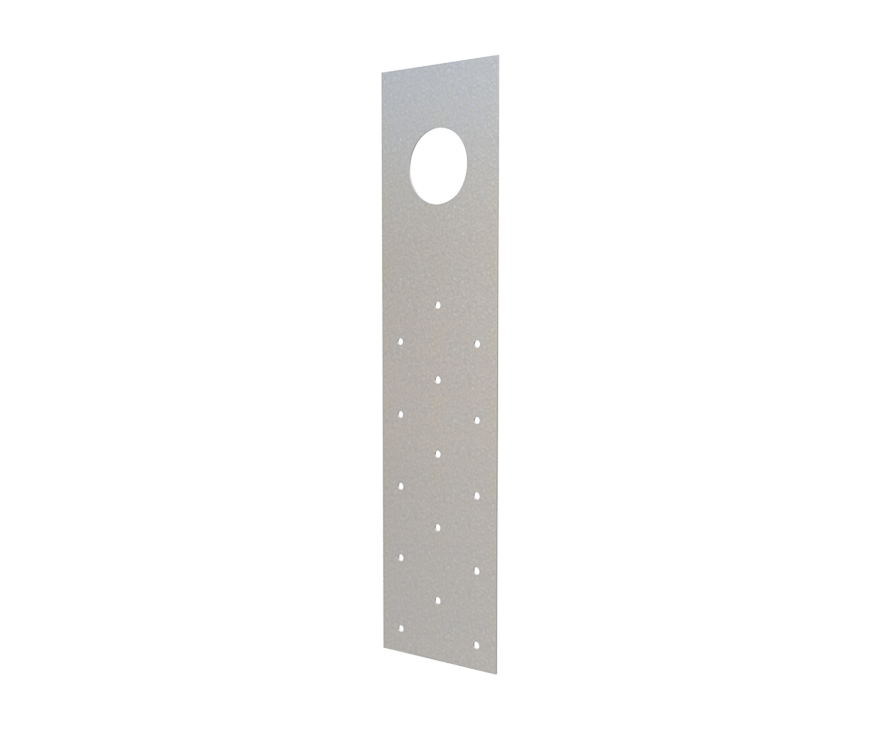

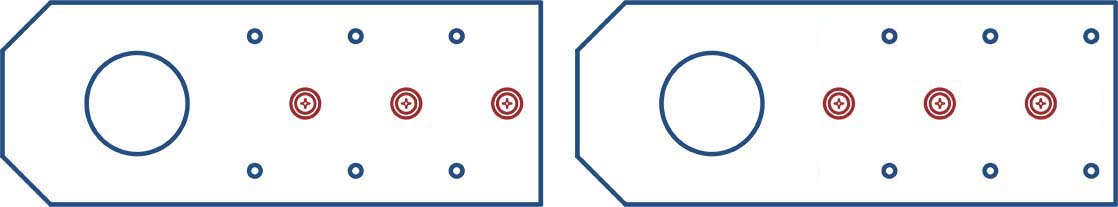

StiffClip PLC is available in two sizes and is designated by the length of the clip, followed by mil thickness (-97).

Example: 8″ connector

Designate: StiffClip® PLC-8-97

StiffClip® PLC Downloads

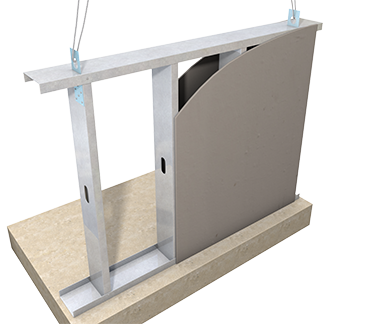

StiffClip® PLC Applications

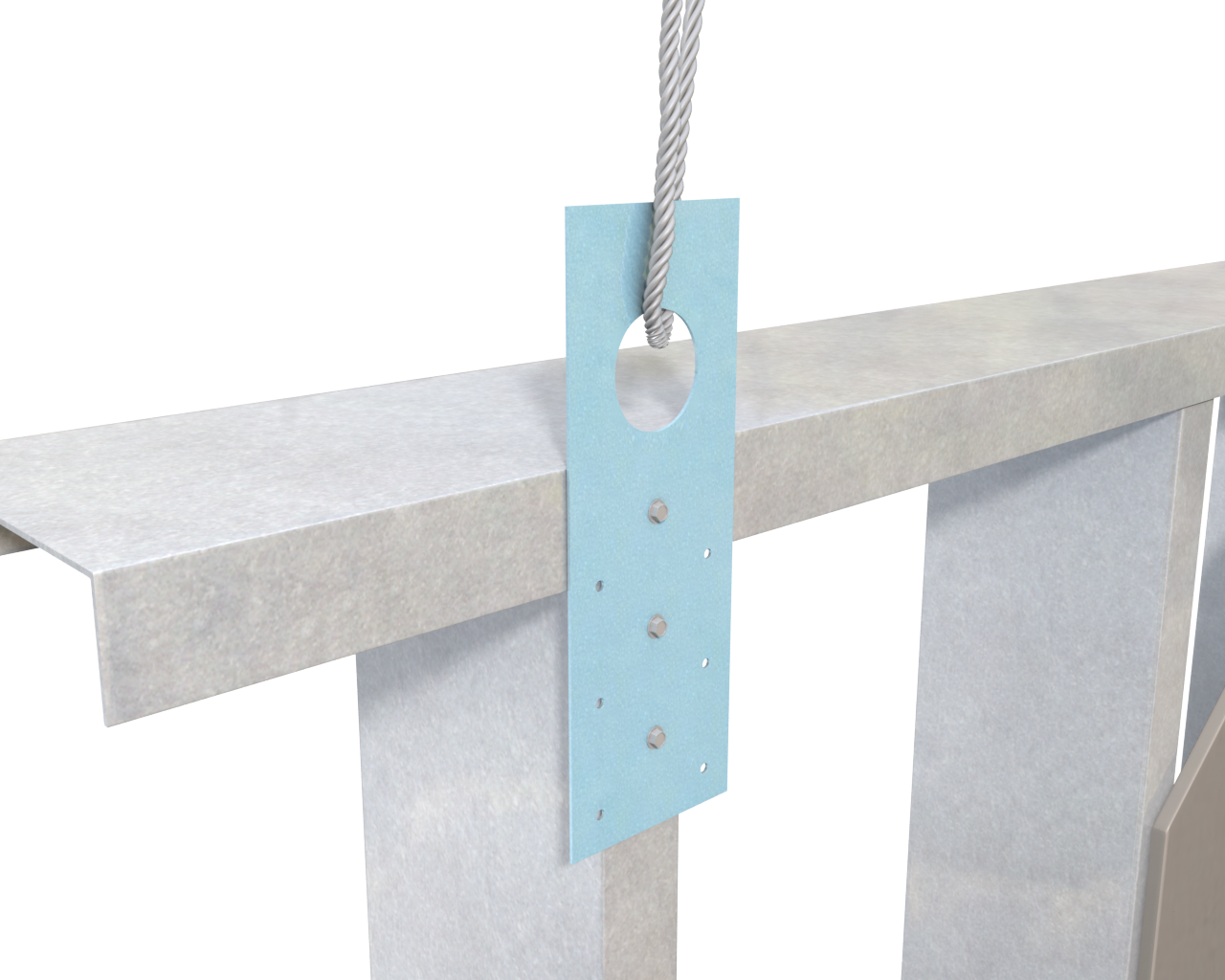

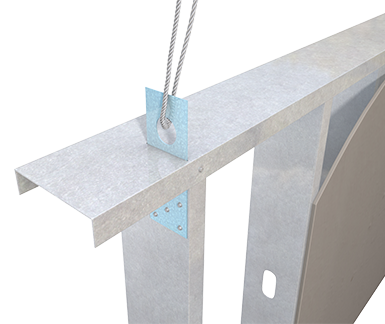

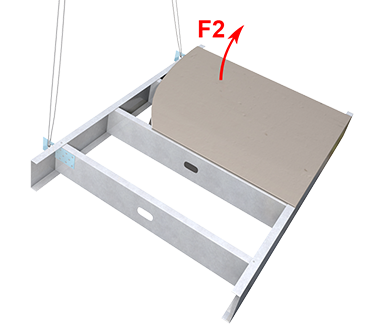

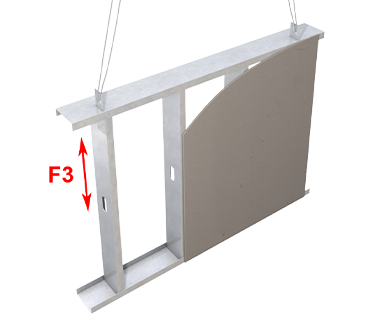

Lifting Panel into Position

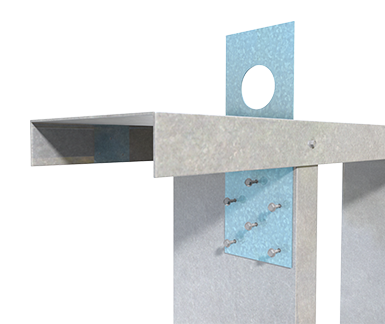

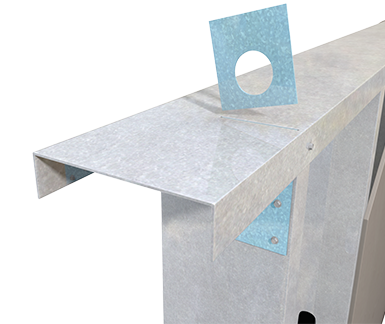

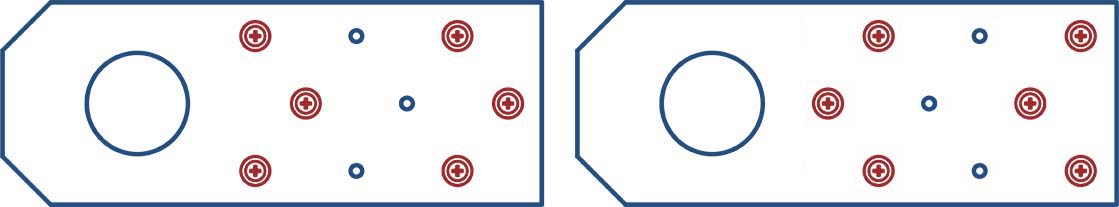

Attachment to Wall at Intermediate Stud

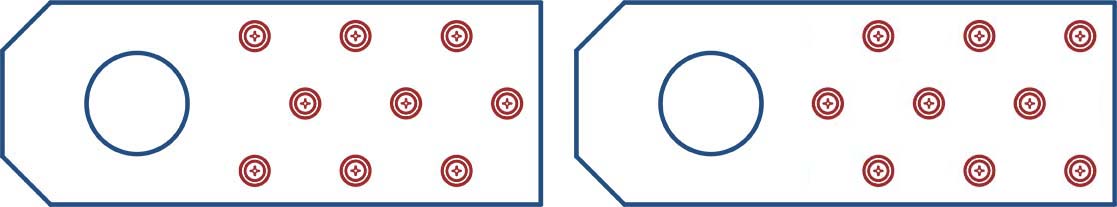

Double Attachment to Wall at End Stud

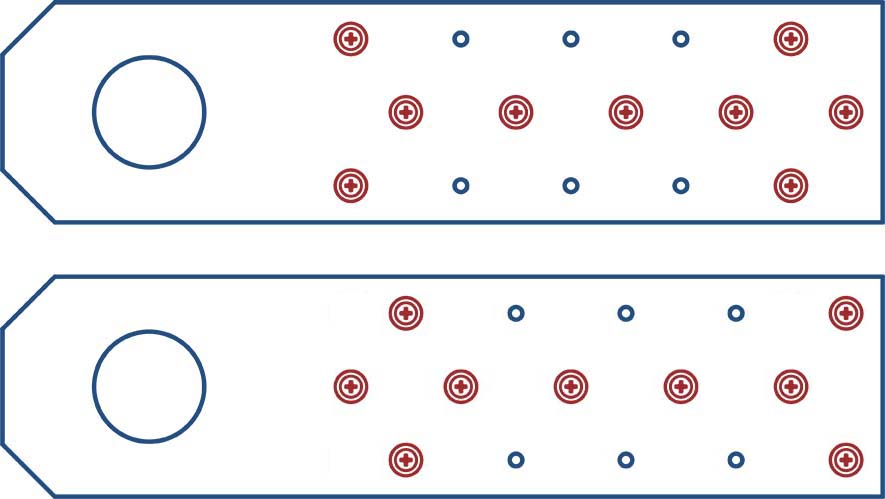

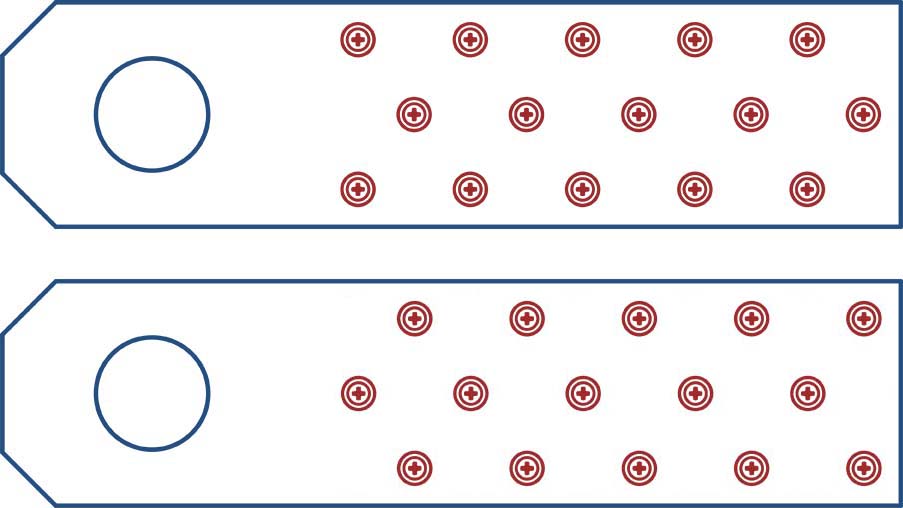

Attachment to Stud Web

Installation Instructions

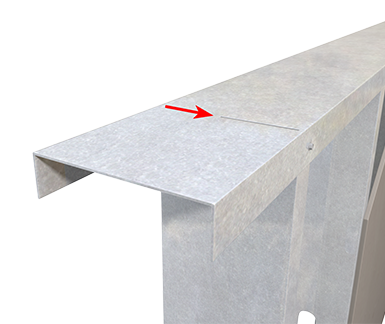

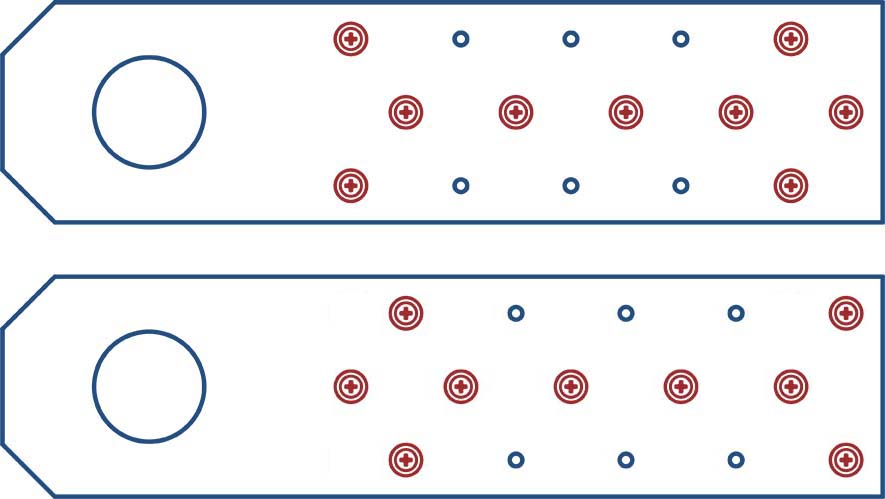

Step 1: Cut slot in top track of panel

Step 2: Insert PLC through slot

Step 3: Attach StiffClip® PLC to stud through guide holes with approved screws

Step 4: Insert lifting cable through 1.5" hole

Step 5: Lift panel into place

Step 6: Trim top of clip flush with the top track of installed panel

Allowable Loads

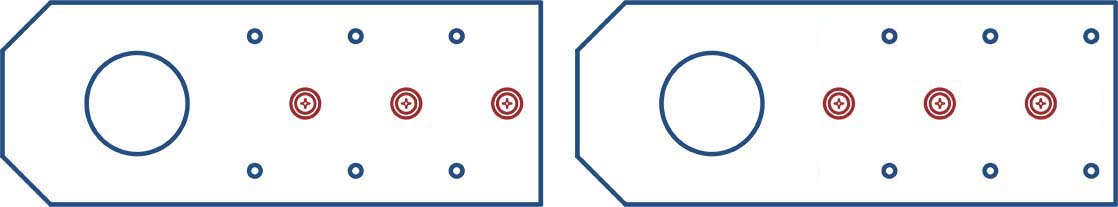

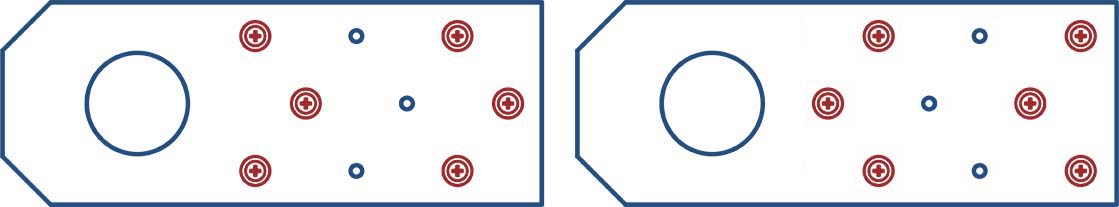

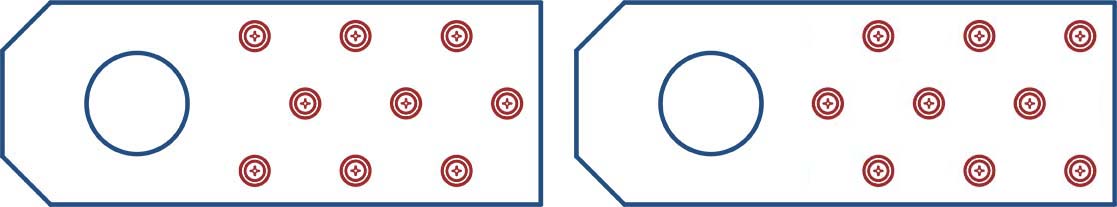

3 Screws

3 Screws 6 Screws

6 Screws 9 Screws

9 Screws 5 Screws

5 Screws 9 Screws

9 Screws 15 Screws

15 Screws 3 Screws

3 Screws 6 Screws

6 Screws 9 Screws

9 Screws 5 Screws

5 Screws 9 Screws

9 Screws 15 Screws

15 ScrewsLoad Table Notes

- Design loads consider loads on the clip and #10 screw fasteners to steel framing.

- Spacing between clips to be controlled by the weight of panel and presence of a spreader bar or a load distribution member

- For screw patterns other than standard patterns shown, contact TSN technical services.

- For LRFD strengths contact TSN technical services.

F2 Load Direction

F3 Load Direction

Follow us on Social Media